Turnover mechanism for guitar coating

A flipping mechanism and guitar technology, applied to the surface coating liquid device, coating, spraying device, etc., can solve the problems of high cost, complex structure, unreliable flipping of the guitar frame, etc., and achieve the effect of smooth and reliable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

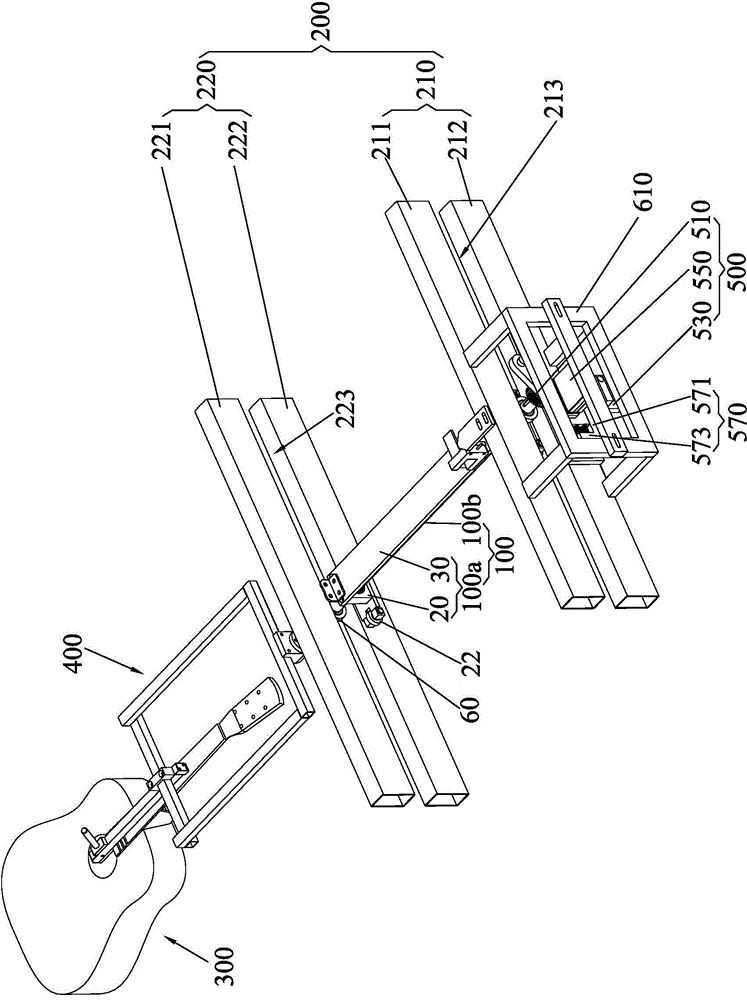

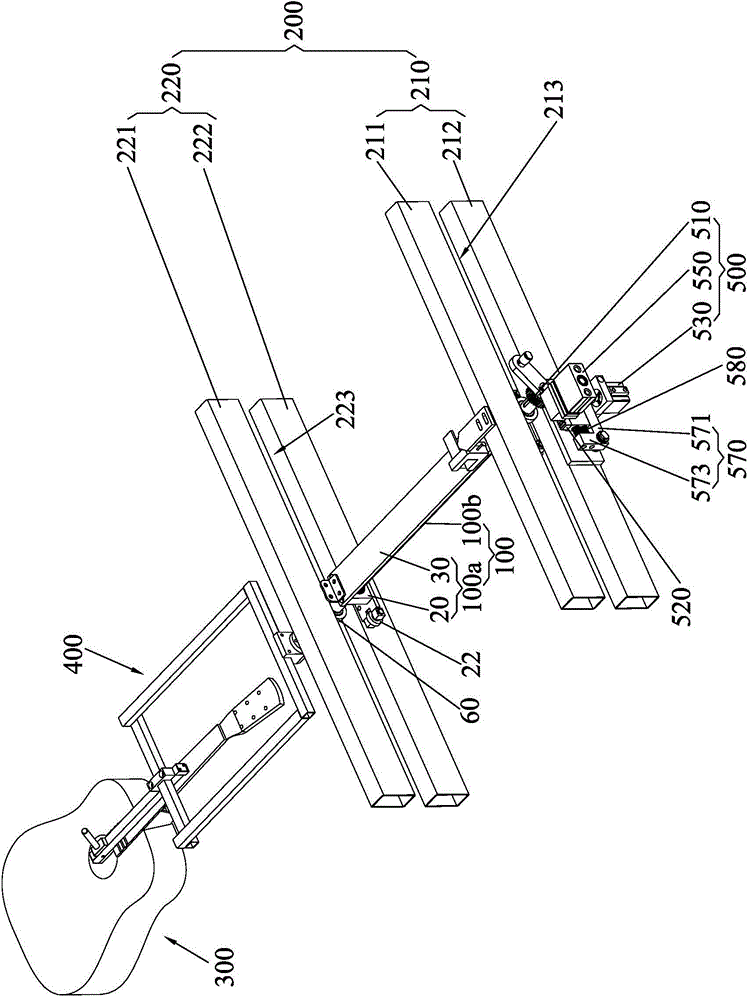

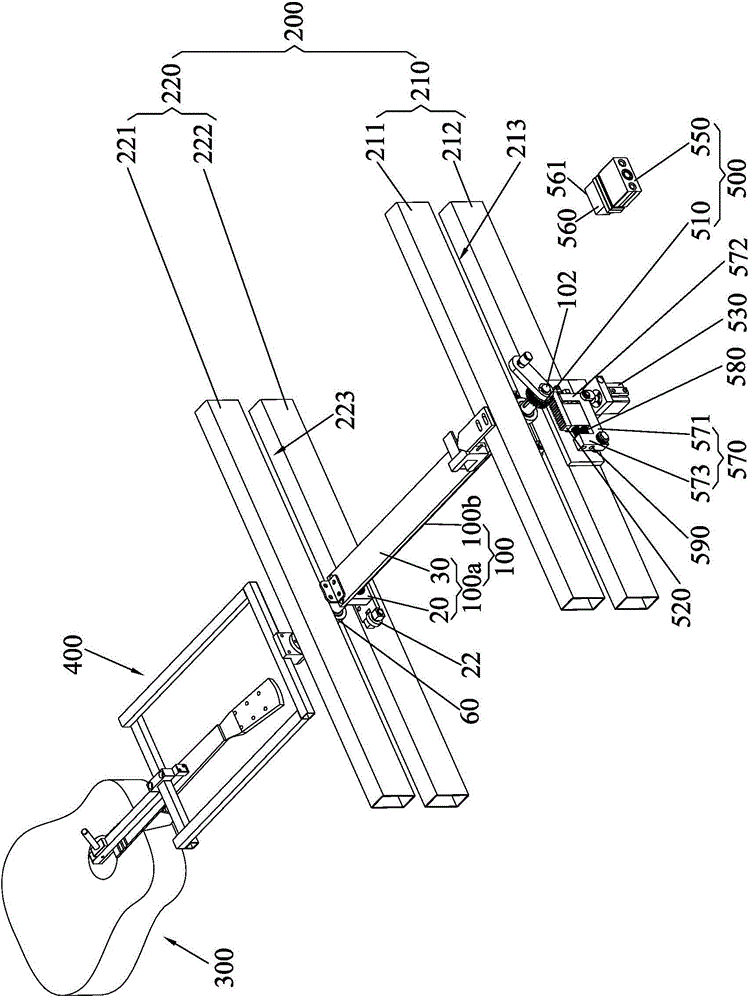

[0031] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

[0032] see Figure 1 to Figure 3 , the turning mechanism 500 for guitar painting of the present invention is suitable for turning the horizontal translation guitar frame 300 carried by the running mechanism 100 from the first position to the second position, specifically, as figure 1 , figure 2 or image 3 As shown, the sound hole 312 of the guitar frame body 300 is defined upwards as the first position, and correspondingly, the sound hole 312 of the guitar frame body 300 is defined as the second position downwards. Of course, in other embodiments, the guitar frame body 300 The sound hole 312 of the guitar frame body 300 is positioned as the first position facing downwards or other states, and correspondingly, the sound hole 312 of the guitar frame body 300 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com