Large-scale modular vibrating screening device and screening method for dry sand making

A vibrating screening, modular technology, applied in chemical instruments and methods, sieves, solid separation, etc., can solve problems such as inability to achieve screening, and achieve the effect of labor-saving replacement and reduced spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

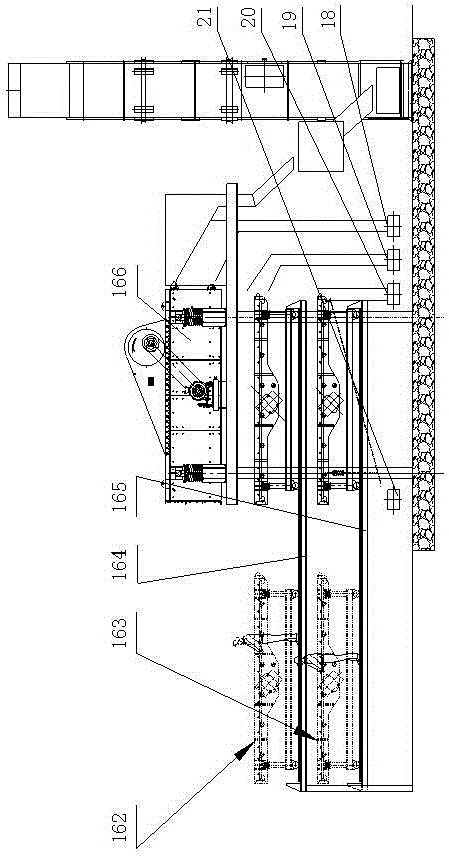

[0015] Embodiment 1: with reference to attached Figure 1-7 . A special modular vibrating screening device for a dry sand production line, consisting of a fixed linear vibrating screen 166, an upper moving linear vibrating screen 162, a lower moving linear vibrating screen 163, an upper linear vibrating screen guide rail 164 and a lower linear vibrating screen guide rail 165 structure; the upper linear vibrating screen guide rail 164 and the lower linear vibrating screen guide rail 165 are arranged in sequence under the fixed linear vibrating screen 166, and the upper linear vibrating screen 162 and the lower movable linear vibrating screen 163 are respectively located on the upper linear vibrating screen guide rail. 164 and the lower linear vibrating screen guide rail 165. The fixed linear vibrating screen 166 is composed of two layers of screens and the distance between the upper screen and the lower screen is greater than 80 cm and less than 100 cm. The upper movable line...

Embodiment 2

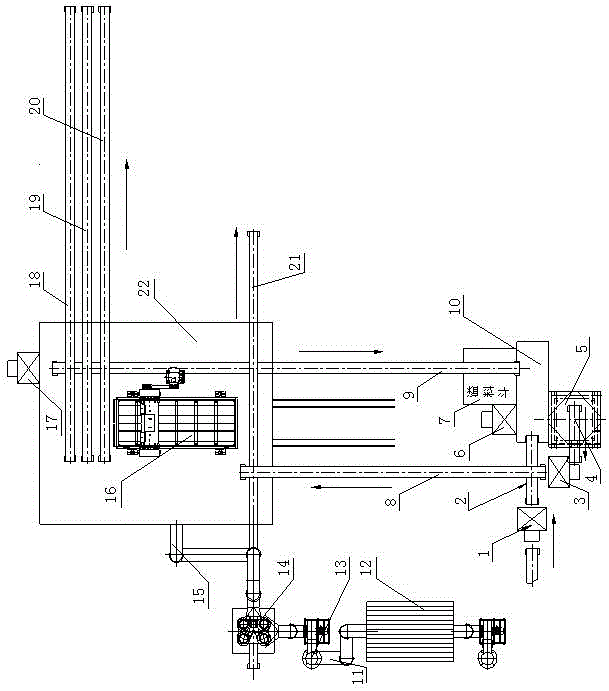

[0018] Embodiment 2: On the basis of Embodiment 1, a screening method of a special modular vibrating screening device for a dry sand production line, the discharge part of the sand mixing conveyor belt 8 discharges the sand to the modular vibrating screening device The upper screen of the fixed linear vibrating screen 166 in 16 sieves the coarse sand and gravel that exceeds the standard and enters the feeding part of the return bucket elevator 17 through the material guide channel; the fixed linear vibrating screen 166 in the modular vibrating screening device 16 The coarse sand sieved by the lower sieve goes directly to the feed end of the coarse sand conveyor belt 18 through the material guide channel, and the coarse sand conveyor belt discharge end guides the coarse sand into the designated coarse sand stockpile; the modular vibrating screening device 16 The medium sand sieved by the upper movable linear vibrating screen 162 goes directly to the feeding end of the medium san...

Embodiment 3

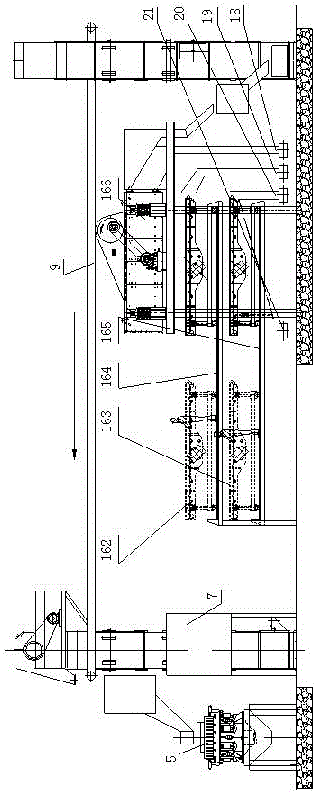

[0019] Embodiment 3: with reference to attached figure 2 and 3. On the basis of Example 1, a dry sand production line, the discharge port of the hopper elevator 1 is connected to the feed port of the hopper 10 through the conveyor belt 2, and the discharge port of the hopper 10 is fed to the conical sand making machine 5 The discharge port of the cone sand making machine 5 is directly facing the feeding part of the sand mixing conveyor belt 4, and the discharging part of the sand mixing conveyor belt 4 is directly facing the feeding part of the sand mixing bucket elevator 3, and the sand mixing The discharge port of the bucket elevator 3 is directly facing the feeding part of the sand mixing conveyor belt 8, and the discharging part of the sand mixing conveyor belt 8 is directly facing the feeding part of the modular vibrating screening device 16, and the modular vibrating screening device The device 16 sieves the coarse sand that exceeds the standard and enters the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com