High-pressure rotary spray gun

A technology of rotating spray guns and rotating nozzles, which is applied to spraying devices, spraying devices with movable outlets, cleaning hollow objects, etc., which can solve problems such as unevenness, laborious, unclean cleaning, etc., and achieve convenient back and forth movement, time-saving and labor-saving processing Quality, mobile-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

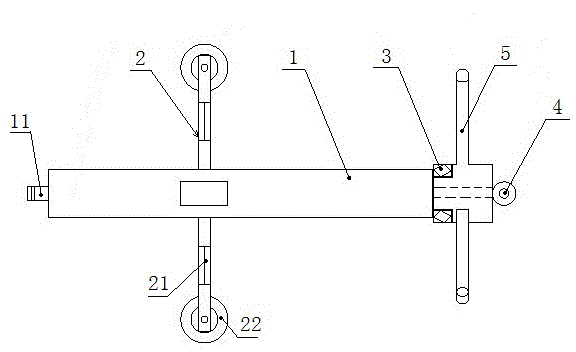

[0013] figure 1 Shown is the structural representation of the present invention.

[0014] The present invention comprises a spray gun rod 1, a telescopic support wheel 2 and a rotating spray head 5, the spray gun rod 1 is provided with a hollow cavity, and its tail is provided with a high-pressure air connection port 11, and the telescopic support wheel 2 is fixed on the spray gun Outside the rod 1, the rotary nozzle 5 is installed on the head of the spray gun rod 1 through the bearing 3,

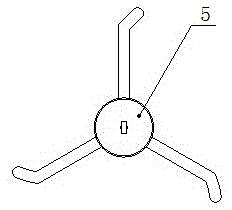

[0015] figure 2 Shown is a schematic structural view of the rotary nozzle of the present invention.

[0016] The rotary spray head 5 is provided with three spray heads with ends bent in the same direction, and the hollow cavity of the spray head communicates with the hollow cavity of the spray gun rod 1 .

[0017] Sealing pads are provided between the rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com