A kind of lc shaped steel and its manufacturing method

A manufacturing method and section steel technology, applied in the field of steel manufacturing, can solve the problems of high labor intensity of workers, limited welding speed, and many processes, and achieve the effects of low labor intensity of workers, reduction of manpower and electricity, and environmental protection of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

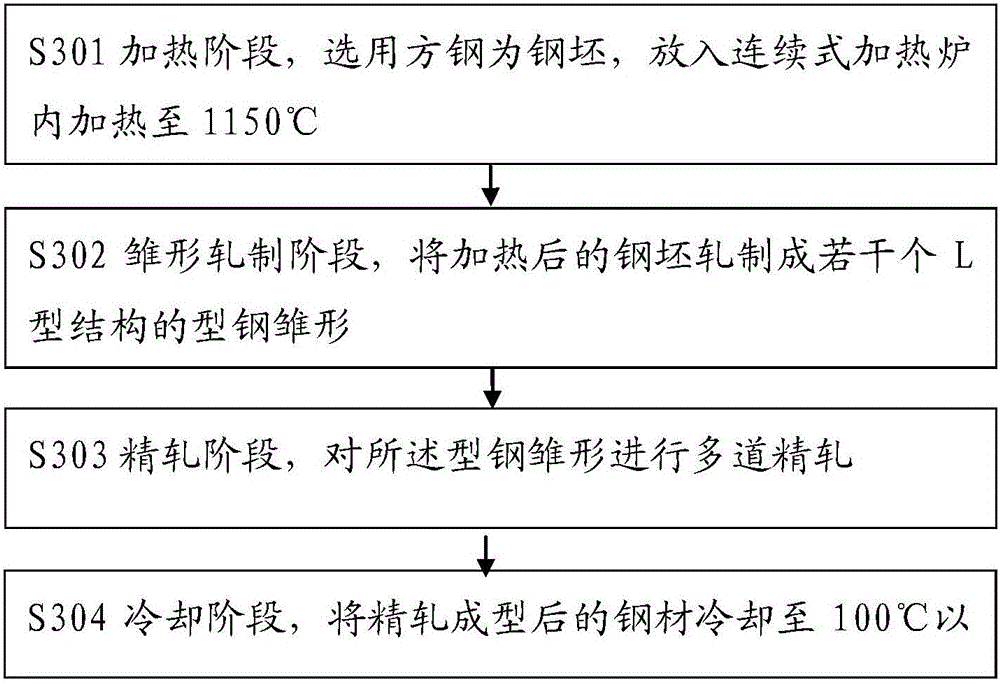

Method used

Image

Examples

Embodiment

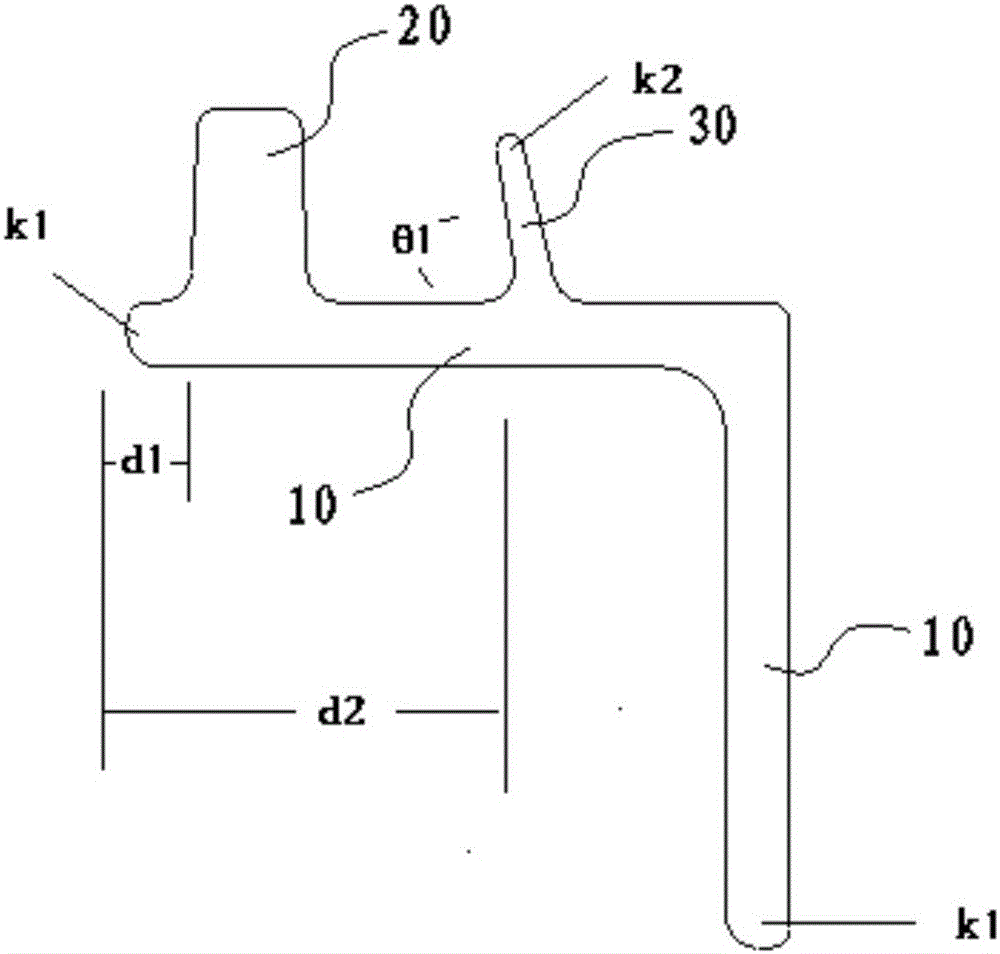

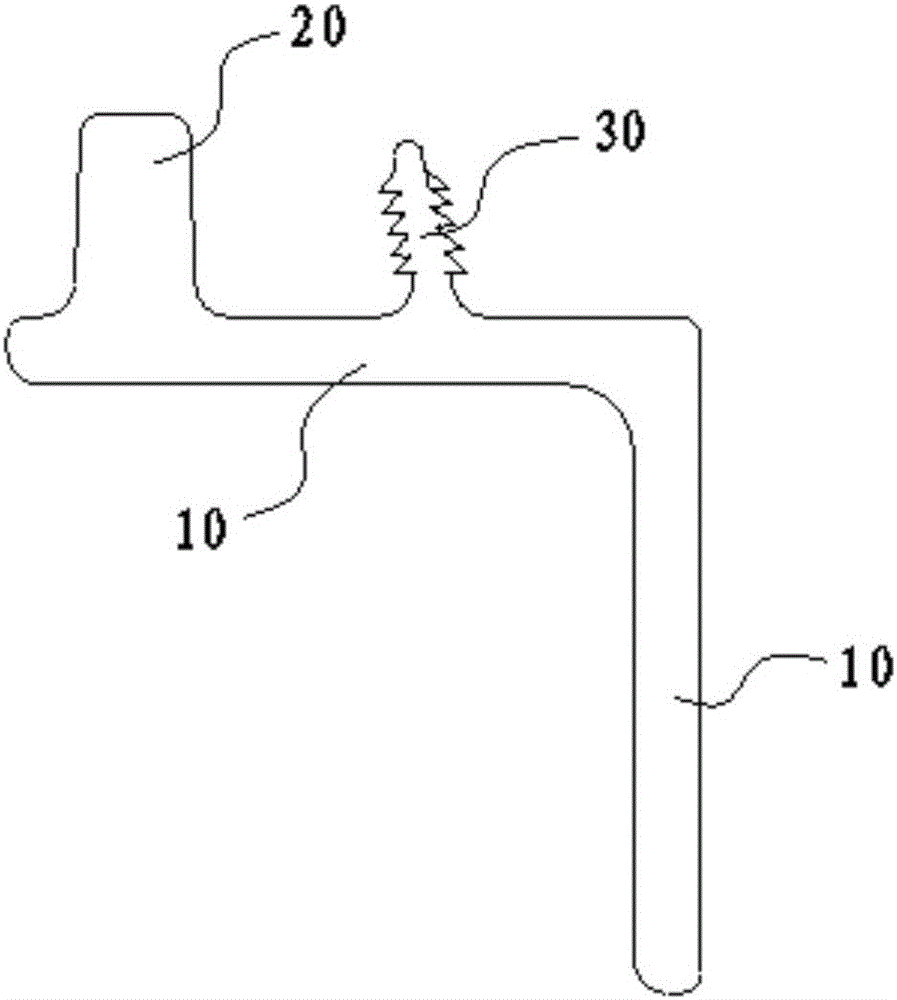

[0058] Such as figure 1 As shown, a kind of LC section steel, it comprises the section steel main body 10 that is inverted L shape and the first steel body and the second steel body that are arranged at the top of section steel main body 10, and described first steel body 20, second steel body 30 are positioned at On the upper surface side of the top of the steel body 10, the first steel body 20 is perpendicular to the top of the steel body 10, and the angle θ1 between the second steel body 30 and the top of the steel body 10 is less than 90° and is inclined toward the first steel body 20. The first The steel body 20 and the second steel body 30 are integrally connected with the top of the shaped steel body 10 respectively.

[0059] In this embodiment, the cross-sectional edge k1 of the shaped steel main body 10 is in the shape of an arc protruding outward. The cross-sectional edge k2 of the second steel body 30 is in the shape of an arc protruding outward. The thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com