Gap inducing cracking method for stripping layer during spinning drawing process of thin-walled tube

A technology of peeling layer and thin-walled pipe, which is applied in the field of thin-walled pipe spinning and deep drawing technology, can solve the problems of pipe surface quality defects and inability to draw deep, and achieve the effect of low cost and improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A method for notch-induced cracking of peeled layers in spinning and deep-drawing of thin-walled tubes, the specific steps of which are:

[0019] (1) Prefabricated gaps on the tube blank before deep drawing

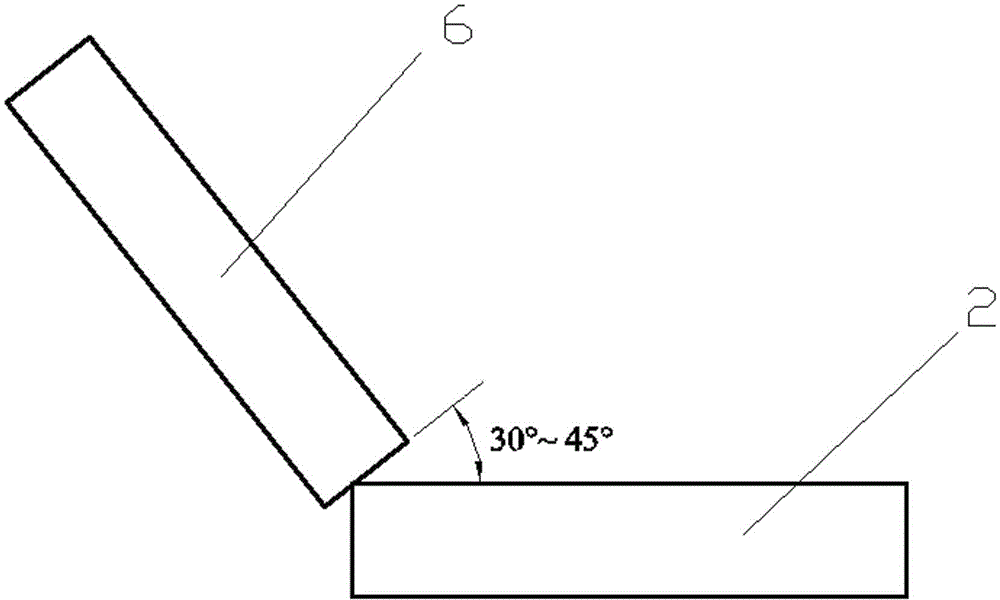

[0020] Use a sharp cutting tool to carve out dents at the rounded corners of the outer surface of the tube blank before deep drawing with an appropriate force, the depth is 0.1~0.3mm, and the angle between the cutting edge of the cutting tool and the tube wall is 30°~45°, such as figure 2 shown.

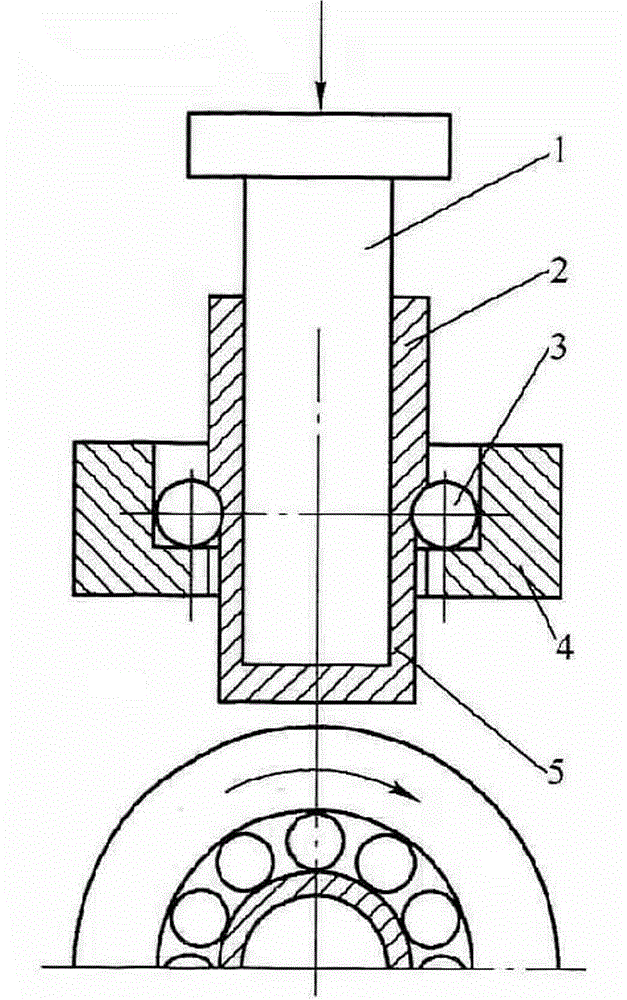

[0021] (2) Spinning and deep drawing of the tube blank with prefabricated gap

[0022] The tube blank with the prefabricated notch is spun and drawn on the mold. The drawing process starts from the end of the tube blank with the notch. The tube blank contacts the ball and becomes thinner and produces a peeling layer. Under the induction of the dent, the surface layer When the metal is peeled off, the notch crack is formed spontaneously, and it is maintained in the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com