Anti-cracking high-strength coral mortar and preparation method thereof

A coral sand and high-strength technology, which is applied in the field of construction mortar, can solve the problems of poor workability, irregular shape, and high water absorption of coral mortar, so as to improve the strength and drying shrinkage behavior, reduce the use of cement, and reduce the heat release of hydration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

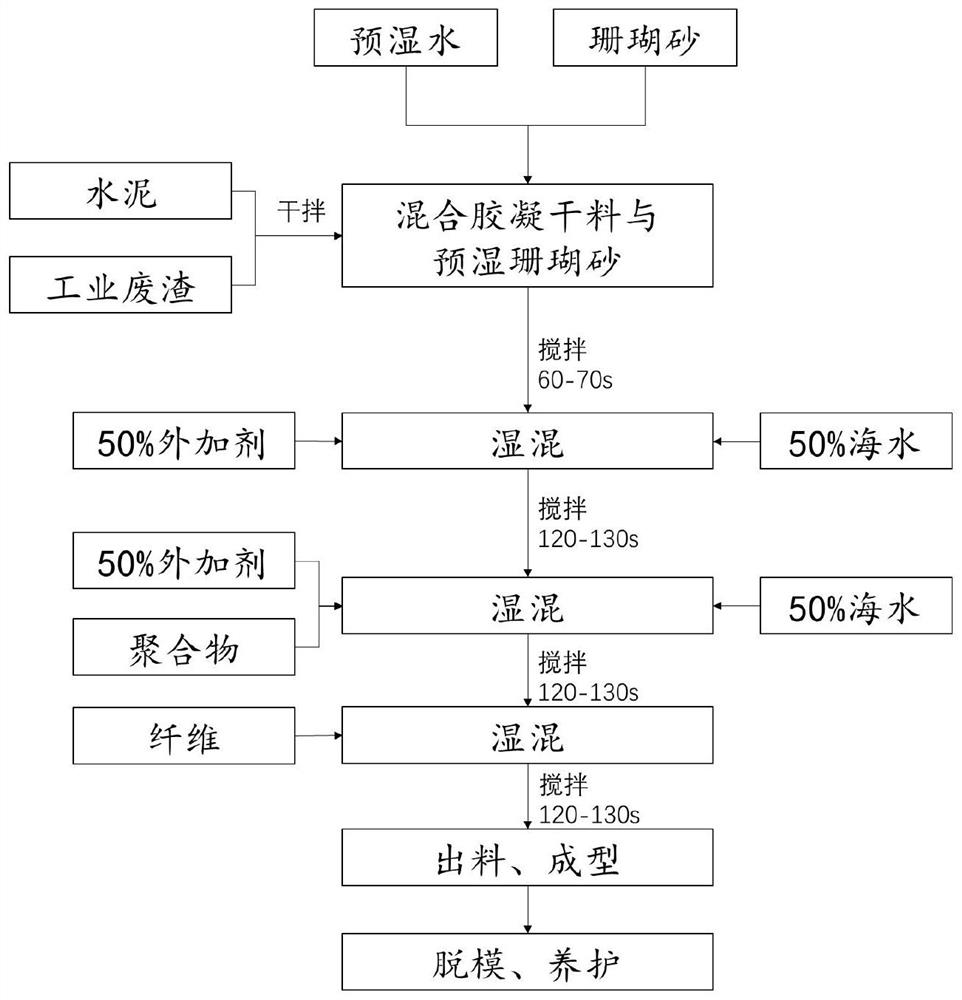

Method used

Image

Examples

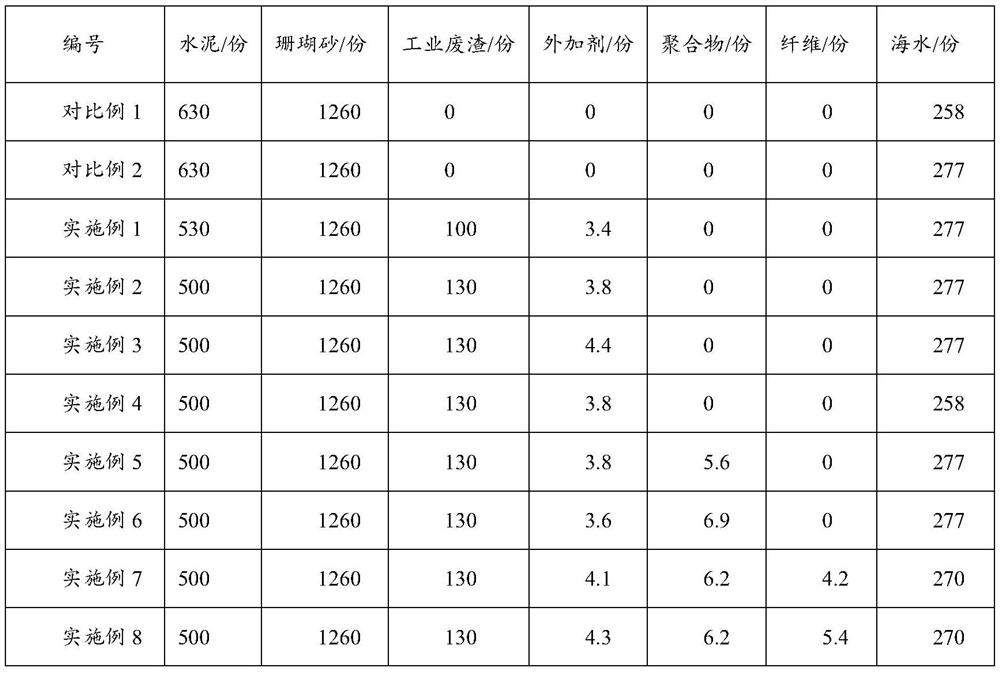

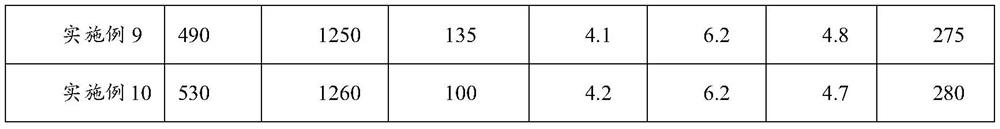

Embodiment 1

[0071] It can be seen from Example 1 and Example 4 that the reduction of the water-to-binder ratio improves the strength of coral mortar, but significantly reduces the fluidity;

[0072] It can be seen from Examples 5-8 that the addition of the polymer improves the tensile bond strength of the mortar and significantly improves the crack resistance of the coral mortar; with the incorporation of fibers, the cracking index decreases significantly; the cracking index increases with the polymer. and decreased with an increase in fiber incorporation;

[0073] It can be seen from Table 2 that the 28-day compressive strength of Examples 7-10 is all super high by 70MPa, which is more than 60% higher than that of Comparative Examples 1-2, and the fluidity is basically controlled between 170-200mm; Compared with the comparative example 1-2, the cracking index of Example 7-10 is greatly reduced; compared with the comparative example, the coral mortar of Example 7-10 has high compressive s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com