Conversion method for hydrocarbon oil

A hydrocarbon oil and catalyst technology, applied in the field of hydrocarbon oil conversion, can solve the problem of not being able to increase the conversion rate of hydrocarbon oil and hydrogen production rate at the same time, and achieve the effect of easy cracking, increase conversion rate of hydrocarbon oil, and increase production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This example is used to illustrate the hydrocarbon oil conversion method provided by the present invention.

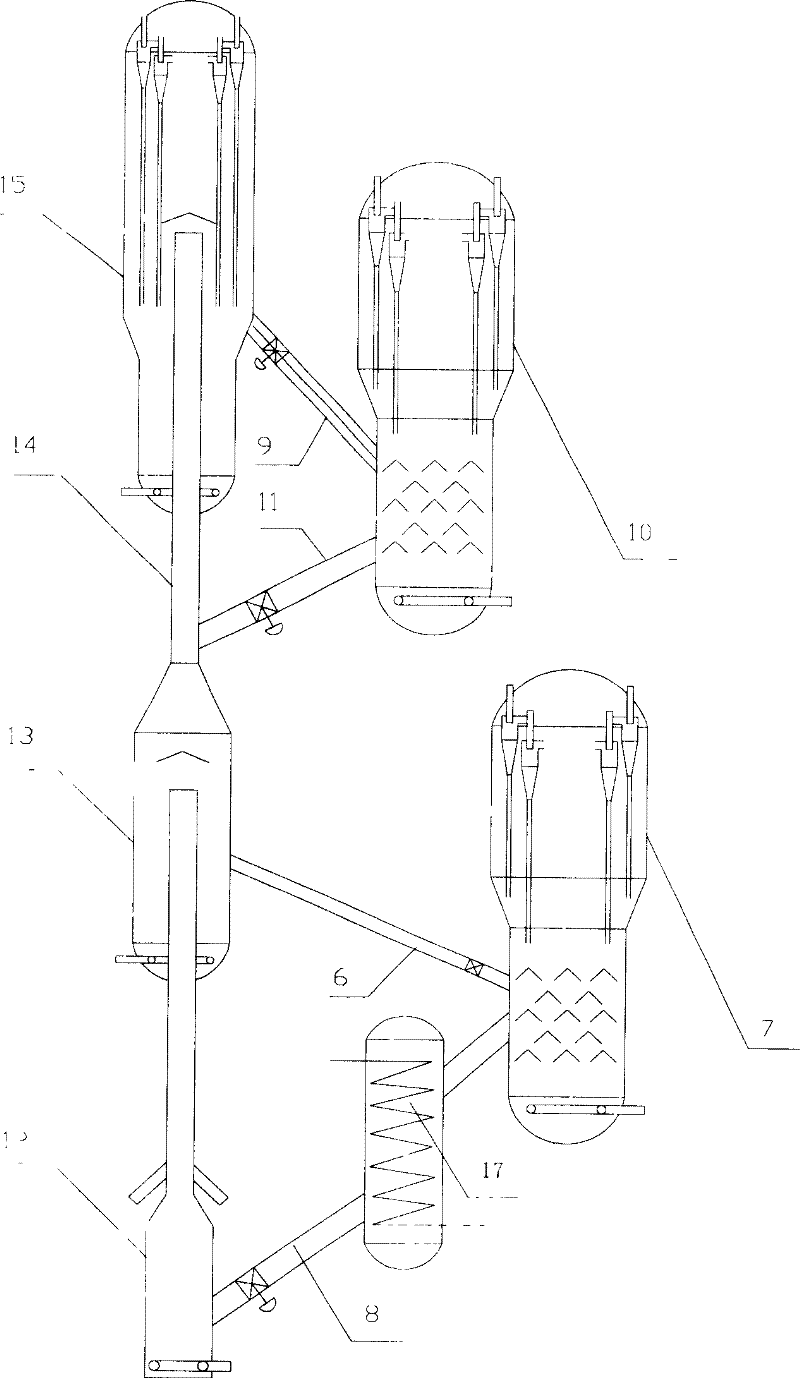

[0054] Such as figure 2 As shown, the regenerated hydrogen production catalyst enters the bottom of the first riser reactor 12 from the first regenerator 7 through the transfer line 8 after being cooled by the cooler 17, and its temperature is cooled from 927°C to 650°C. The hydrogen production catalyst is contacted with hydrocarbon oil at a temperature of 200°C in the first riser reactor. The reaction conditions are as follows: the reaction temperature is 480°C, the reaction pressure is 120 kPa (table), the weight ratio of hydrogen production catalyst to hydrocarbon oil is 4:1, and the reaction time is 3 seconds.

[0055]The above-mentioned reaction products and the hydrogen production catalyst to be produced enter the first settler 13 and are separated there. The separated standby hydrogen production catalyst enters the first regenerator 7 after steam strip...

Embodiment 2

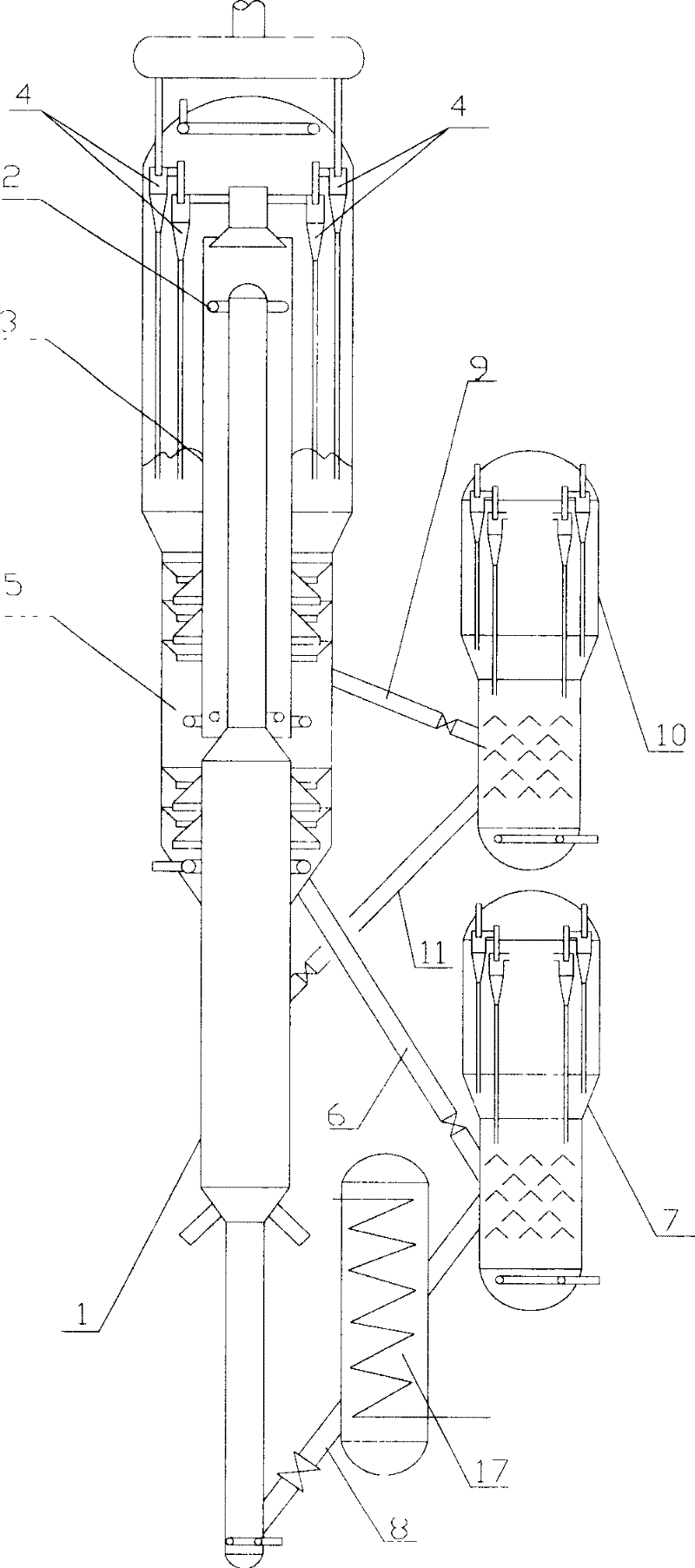

[0066] according to figure 1 The embodiment shown carries out the conversion of hydrocarbon oil, and the reaction conditions for the hydrogen production catalyst and the hydrocarbon oil to contact the lower part of the riser reactor 1 for the precracking reaction are as follows: the reaction temperature is 500° C., and the reaction pressure is 250 kPa (table), The weight ratio of the hydrogen production catalyst to the hydrocarbon oil is 6:1, and the reaction time is 2 seconds; the conditions for the hydrogen production catalyst to be produced to be in contact with the mixed gas of water vapor and oxygen are: the contact temperature is 1100°C, the pressure is 280 kPa, The molar ratio of water vapor and oxygen in the mixed gas is 2.5:1, and the contact time is 100 seconds. The reaction product after the reaction is in contact with the cracking catalyst in the middle and upper part of the riser reactor 1 to carry out the cracking reaction. The cracking reaction conditions are a...

Embodiment 3

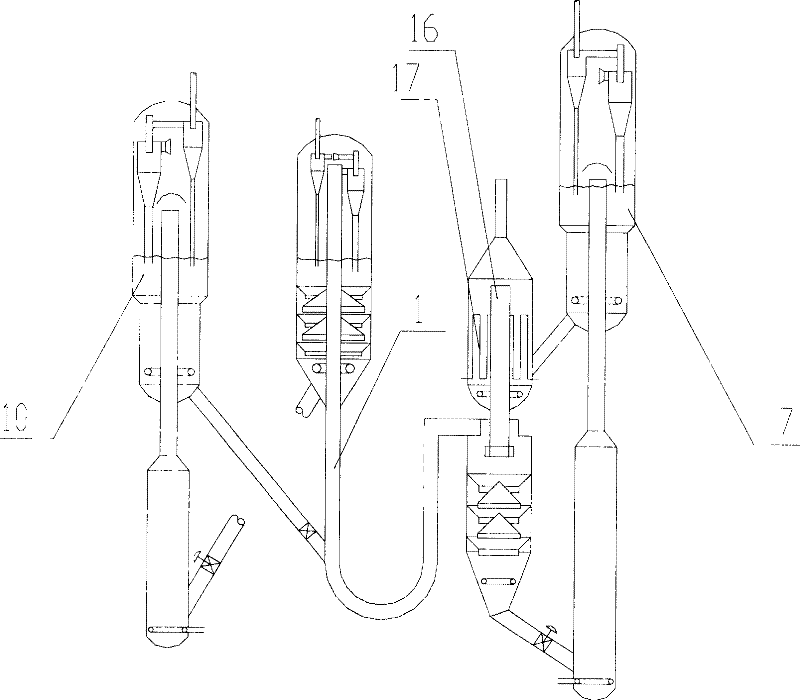

[0068] according to image 3 In the embodiment shown, hydrocarbon oil conversion is carried out. The reaction conditions for the hydrogen production catalyst and hydrocarbon oil to contact in the downcomer for precracking reaction are: the reaction temperature is 520°C, the reaction pressure is 380 kPa (table), the hydrogen production catalyst and the hydrocarbon oil The weight ratio of hydrocarbon oil is 7:1, and the reaction time is 0.3 seconds; the conditions for contacting the raw hydrogen production catalyst with the mixed gas of water vapor and oxygen in the first regenerator are: the contact temperature is 850 ° C, and the pressure is 350 kW Pa (table), the molar ratio of water vapor and oxygen in the mixed gas is 2.8:1, and the contact time is 200 seconds. The reaction product separated after the reaction is contacted with the cracking catalyst in the riser reactor 1 to carry out the cracking reaction. The conditions of the cracking reaction are as follows: the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com