A method that can realize differential control of the flow rate of materials in each phase in a slurry bed reactor

A technology of reactor and slurry bed, which is applied in the field of bioenergy conversion, can solve the problem of less coke, and achieve the effects of no coke polycondensation, simple pretreatment, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

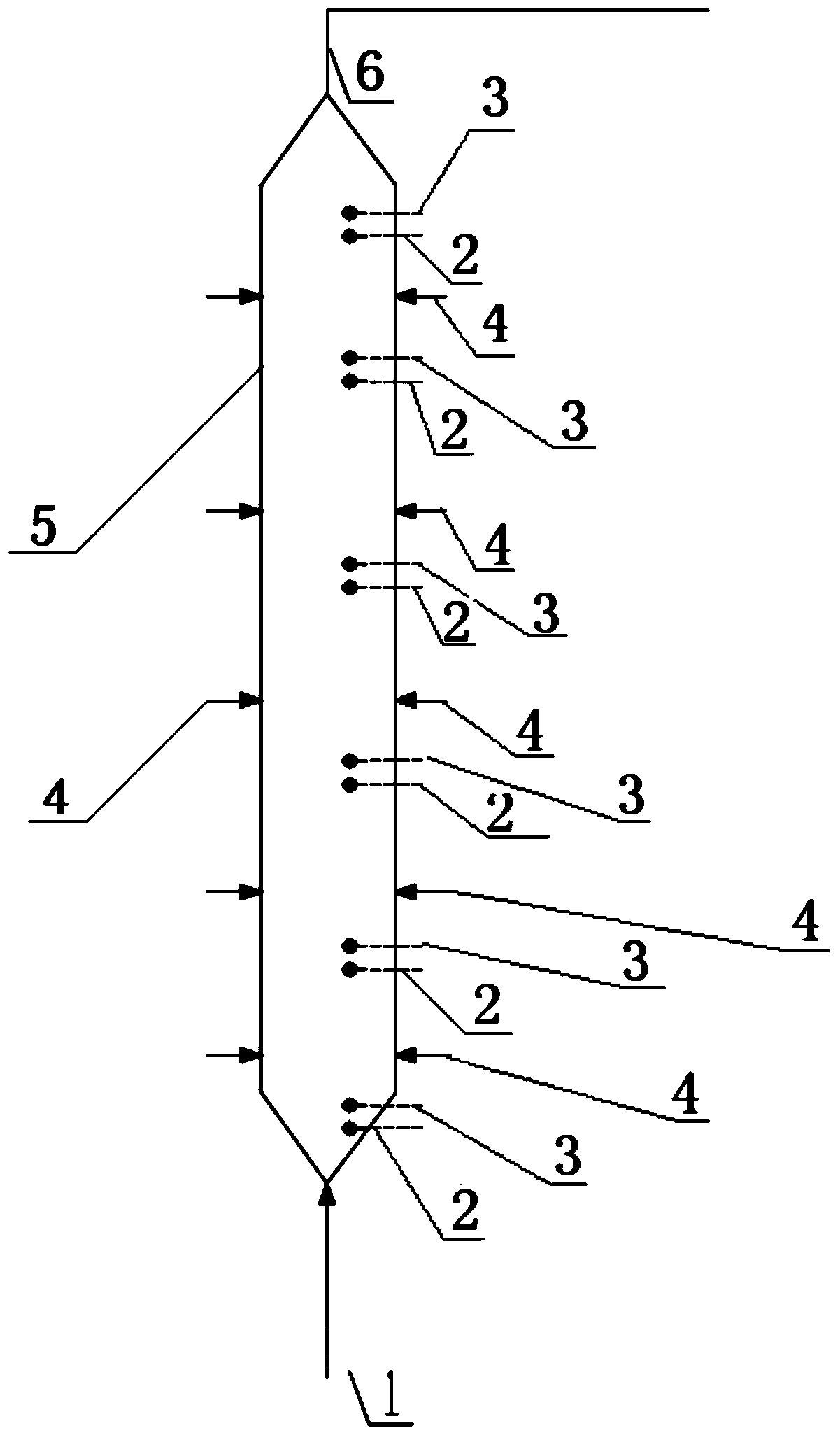

[0037] This embodiment provides a reactor for cracking and hydrogenation controlled by upstream differential velocity, which is a reactor used for the method of controlling the flow rate difference of each phase in a slurry bed reactor, such as figure 1 As shown, the reactor includes a closed shell 5;

[0038] A conical bottom feeding port 1 is located at the bottom of the housing 5;

[0039] A tapered outlet 6 is located on the top of the housing 5;

[0040] The temperature control sensing device 2 and the density measurement sensing device 3 are arranged in pairs on the side wall of the housing 5;

[0041] And the side wall hydrogen injection hole 4, and the side wall hydrogen injection hole 4, the side wall hydrogen injection hole 4 is arranged on the two pairs of the temperature control sensing device 2 and the density measurement sensor arranged in pairs along the cold hydrogen flow direction. On the side wall of the housing between the sensing devices 3.

[0042] The ...

Embodiment 2

[0050] This embodiment provides a method that can realize the difference control of the material flow rate of each phase in the slurry bed reactor. Using the reactor described in Embodiment 1, the aspect ratio of the first reactor used in this embodiment is 15:1. Specific steps are as follows:

[0051] (1) Deash corn stalks with a particle size of 1-50 μm to obtain straw granules, and amorphous alumina loaded with Mo oxides and Ni oxides (with a particle size of 5 μm-50 μm and a specific surface area of 150 m 2 / g; the heap specific gravity of the catalyst is 0.8; the average pore diameter of the catalyst is 5nm) and the mixture obtained by mixing the straw particles and sulfur in a mass ratio of 5:100:0.3 is added to medium-low temperature coal tar to form a Substance 10wt% slurry;

[0052] (2) Inject hydrogen at 60°C and 13MPa into the slurry for the first time until the volume ratio of high-pressure hydrogen to the slurry is 50:1, then raise the temperature of the slurry...

Embodiment 3

[0055] This embodiment provides a method that can realize the difference control of the flow rate of each phase in the slurry bed reactor. Using the reactor described in Embodiment 1, the aspect ratio of the first reactor used in this embodiment is 10:1. Specific steps are as follows:

[0056] (1) Reed particles are obtained after deashing reeds with a particle size of 20-1000 μm, and amorphous alumina loaded with W oxide and Ni oxide (with a particle size of 100 μm-150 μm and a specific surface area of 200 m 2 / g; the bulk specific gravity of the catalyst is 0.7; the average pore diameter of the catalyst is 30nm) and the reed particles and sulfur are mixed in the ratio of iron oxide, reed particles and sulfur in a mass ratio of 2:3:100:0.4 Obtain a mixture, which is added to vegetable oil to form a slurry containing 30 wt% of biomass;

[0057] (2) Inject hydrogen at 70°C and 20MPa into the slurry for the first time until the volume ratio of high-pressure hydrogen to slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com