Method and device for variable material conveying of metal coil numerical control punching

A metal coil, feeding device technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of increased equipment input cost, low processing accuracy, poor stability of stamping working conditions, etc., and achieves economical practicability. , The effect of high stamping precision and process improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

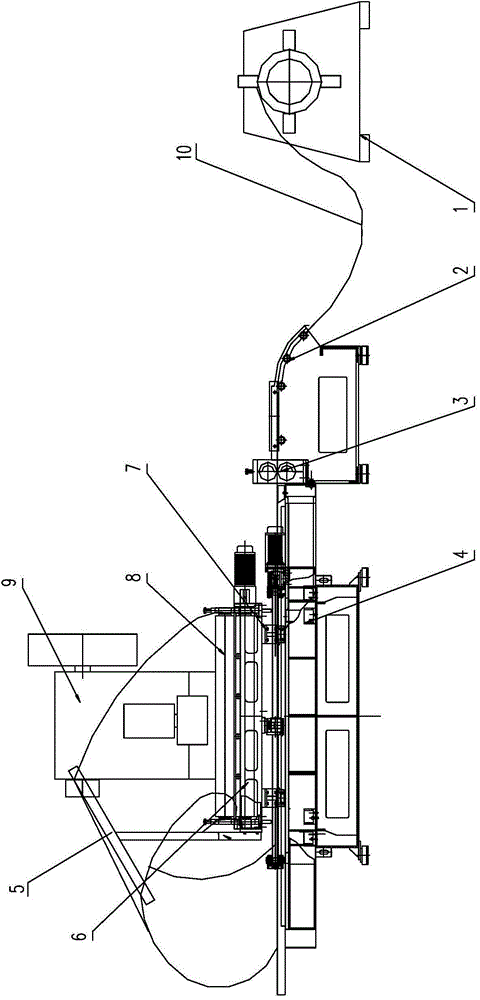

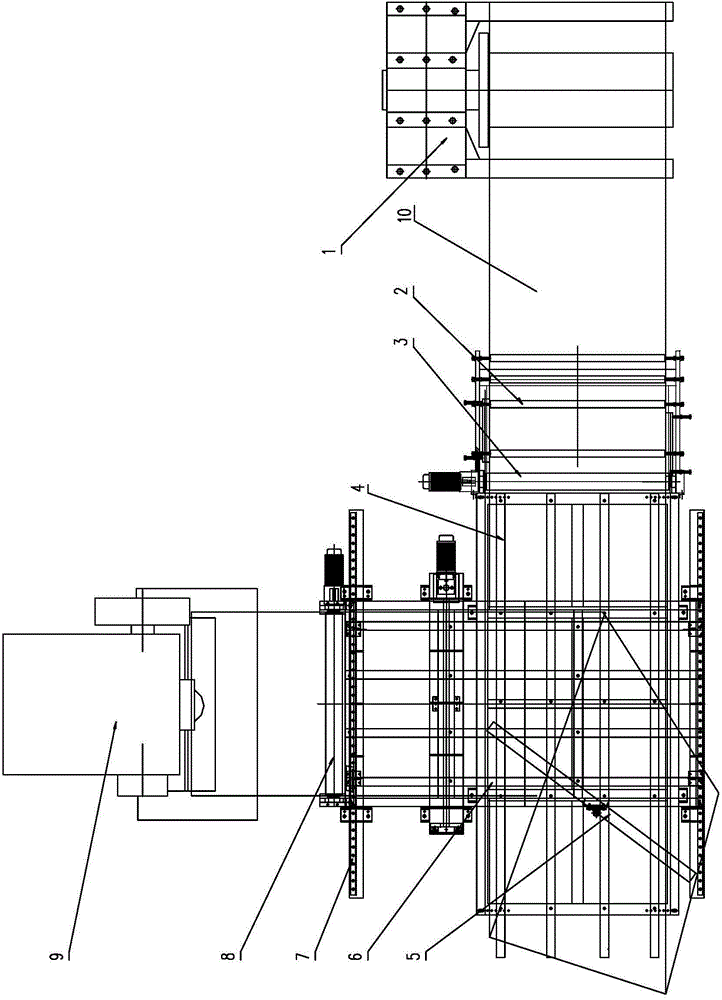

[0026] like Figure 1~2 The shown metal coil numerical control stamping feeding device is mainly composed of an uncoiler 1 used in conjunction with a punching machine 9, a horizontally fixed material receiving platform 4 and a laterally sliding material receiving platform 6 and other components. The uncoiler 1 is arranged on the front side of the punch 9, and the unwinding direction of the metal coil 10 to be processed on the uncoiler 1 is perpendicular to the longitudinal feeding direction of the punch 9 . The horizontally fixed material receiving platform 4 is arranged in front of the punch press 9 and corresponds to the position of the uncoiler 1 . A transverse conveying roller assembly 3 and a guide roller assembly 2 are arranged between the transversely fixed material bearing platform 4 and the uncoiler 1, and the transversely f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com