Tool for machining circular hole in oblique plane and machining method of tool

A processing method and inclined plane technology, which is applied in the direction of drilling molds for workpieces, metal processing equipment, metal processing machinery parts, etc., can solve the problems of affecting the processing quality of round holes, long working hours, and long processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

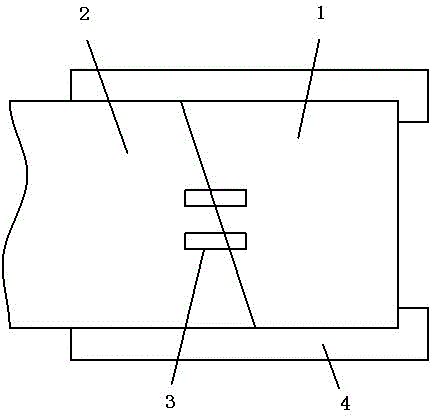

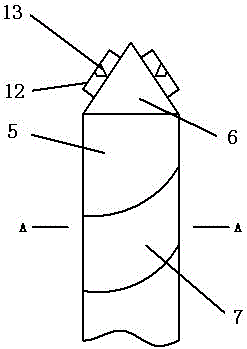

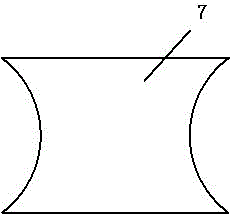

[0030] refer to Figure 1-6 , a specific embodiment of the present invention comprises the spacer 1 that is fixed on the processing slope 2, the inner surface of the spacer 1 contacting with the processing slope 2 is arranged parallel to the processing slope 2, the outer side of the spacer 1 is vertically arranged, and the spacer 1. Two horizontal stoppers 3 are welded on the inner surface in contact with the processing slope 2; a holding mechanism 4 for fixing the pad 1 and the processing slope 2 together; a first drill bit 5 for processing round holes, The top of the first drill bit 5 is provided with the first tapered part 6, and the sidewall of the first drill bit 5 is provided with the first helical cutting groove 7; For the second drill bit 8 of processing circular hole, the top of the second drill bit 8 A second tapered portion 9 is provided, and the side wall of the second drill bit 8 is vertically provided with three second cutting grooves 10, and the side wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com