Saw band with a profiled back

A saw band and special-shaped technology, which is applied in the direction of band saws, saw blades, manufacturing tools, etc., can solve the problems of reduced service life of saw bands, high cutting force, high wear, etc., and achieve the effect of reducing cutting force and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

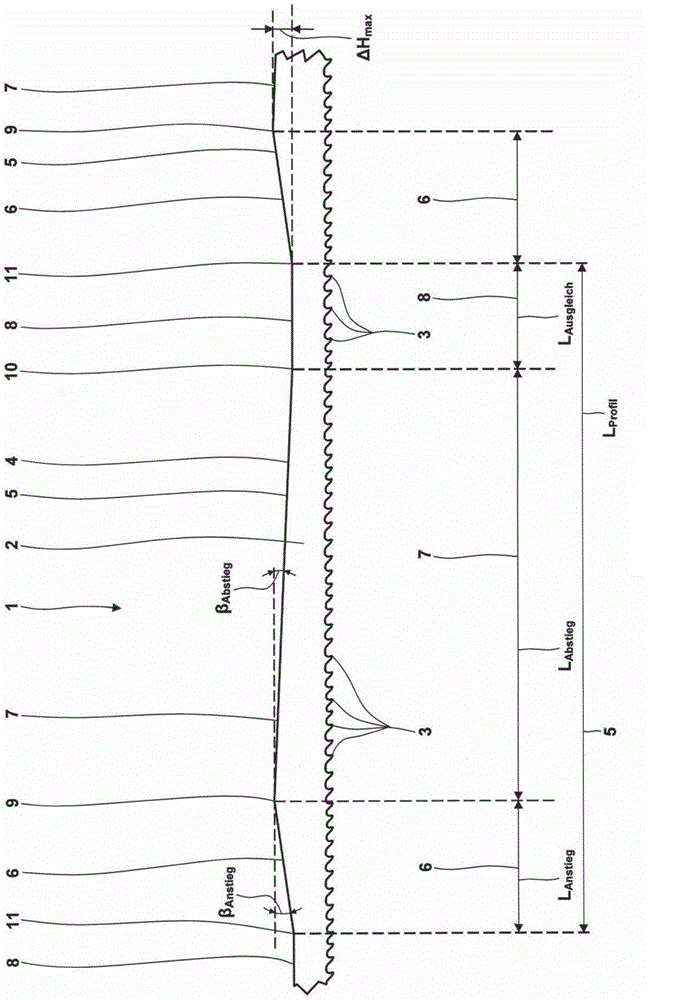

Embodiment 1

[0063] parameter unit value Inclination angle β Anstieg Spend 0.69 Inclination angle β Abstieg Spend 0.21 The length of the rising area L Anstieg mm 100 The length of the drop zone L Abstieg mm 320 The length of the compensation area L Ausgleich mm 80 Length L of back profiled section Profil mm 500 Maximum height difference △H max mm 1.2

[0064] Figure 4 and Figure 5 A second exemplary embodiment of the new saw band 1 corresponding to figure 1 and figure 2 view. In this case, the belt back 4 has a symmetrically shaped belt back profile section 5 . This means that the ascending region 6 and the descending region 7 have a uniform length and a uniform inclination in terms of value.

[0065] The corresponding values for this example are summarized in the table below:

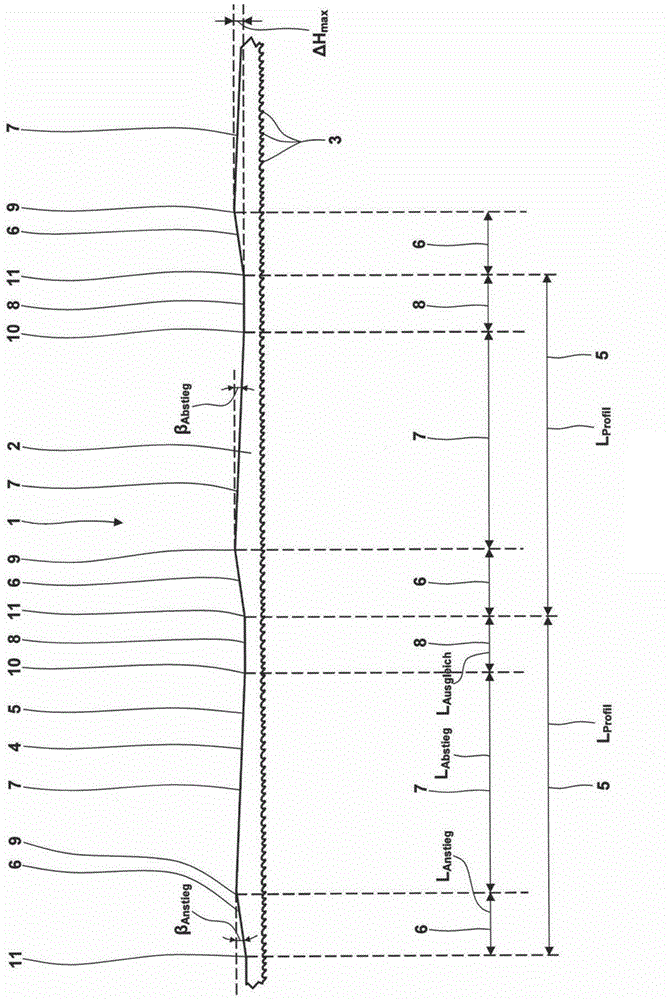

Embodiment 2

[0067] parameter unit value Inclination angle β Anstieg Spend 0.33 Inclination angle β Abstieg Spend 0.33 The length of the rising area L Anstieg mm 210 The length of the drop zone L Abstieg mm 210 The length of the compensation area L Ausgleich mm 80 Length L of back profiled section Profil mm 500 Maximum height difference △H max mm 1.2

[0068] Figures 6A to 6E The novel movement of the saw band 1 in the saw machine is shown. The saw machine itself is generally constructed so that no detailed illustration or description is required. In this case, the saw band 1 has a symmetrical profiled belt-back profiled section 5 . The compensation area 8 is a recessed area.

[0069] The saw machine has guide elements 12 , which are each designed here as individual rollers 13 . The belt back 4 and thus the saw band 1 are guided by the guide element 12 in the region of the workpiece to be sawed (not shown)...

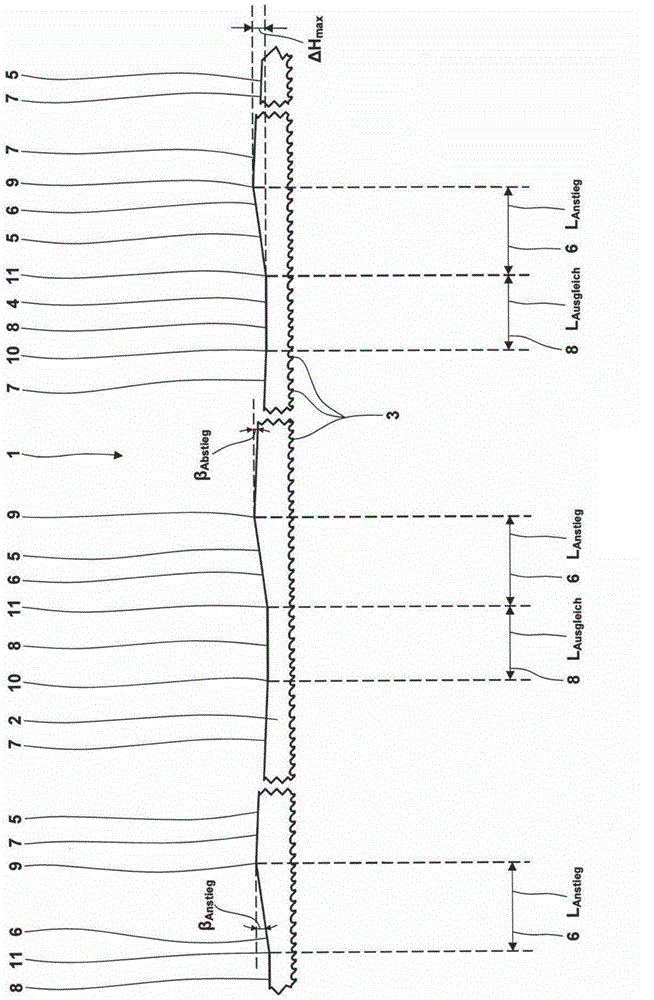

Embodiment 3

[0087] parameter unit value Inclination angle β Anstieg Spend 0.46 Inclination angle β Abstieg Spend 0.13 The length of the rising area L Anstieg mm 150 The length of the drop zone L Abstieg mm 520 The length of the compensation area L Ausgleich mm 80 Length L of back profiled section Profil mm 750 Maximum height difference △H max mm 1.2

[0088] exist Figure 8 An asymmetrically profiled saw band 1 is shown in , which is arranged here in a band saw machine (not shown in detail), which has a guide element 12 designed as a double roller 14 . In the position shown, the left double roller 14 is in contact with the beginning of the drop zone 7. The right double roller 14 is in contact with the beginning of the next rising area 6 on the right, so that overall a counterclockwise tipping position results.

[0089] Figure 9 The saw band 1 shown in has an asymmetrically shaped belt-back profiled section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com