Cutting fluid spraying device for OCV valve

A cutting fluid and spool technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of high processing waste rate, scratching inner hole, affecting the smoothness of inner hole, etc., and achieve a high scrap rate Low, guaranteed cleanliness, high product precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

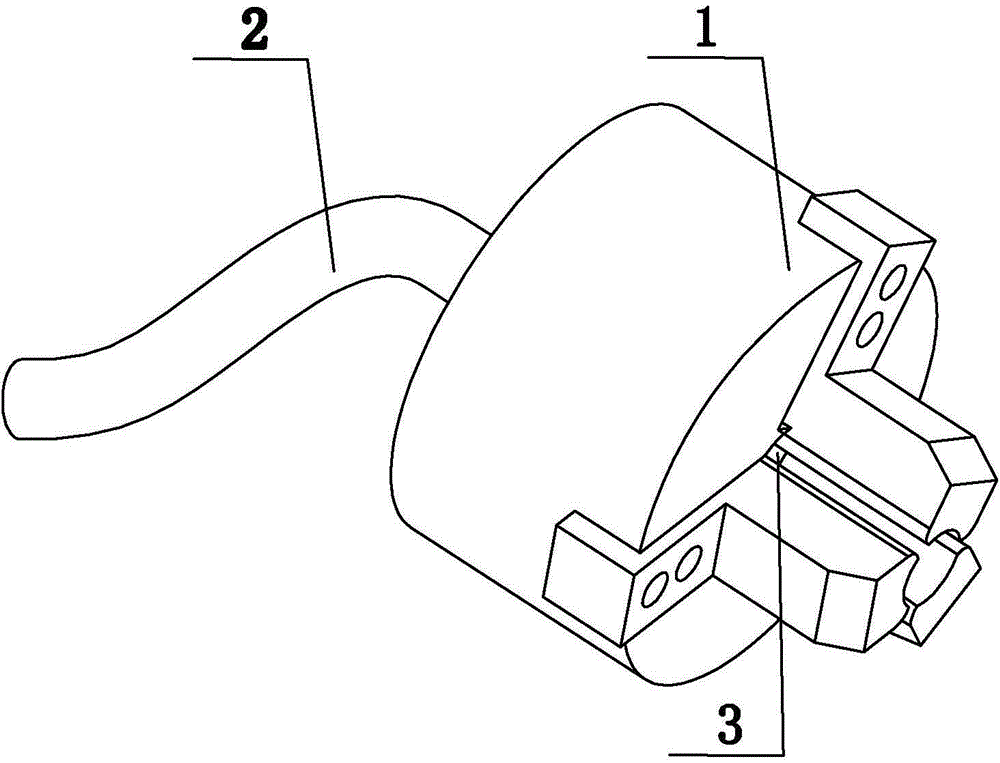

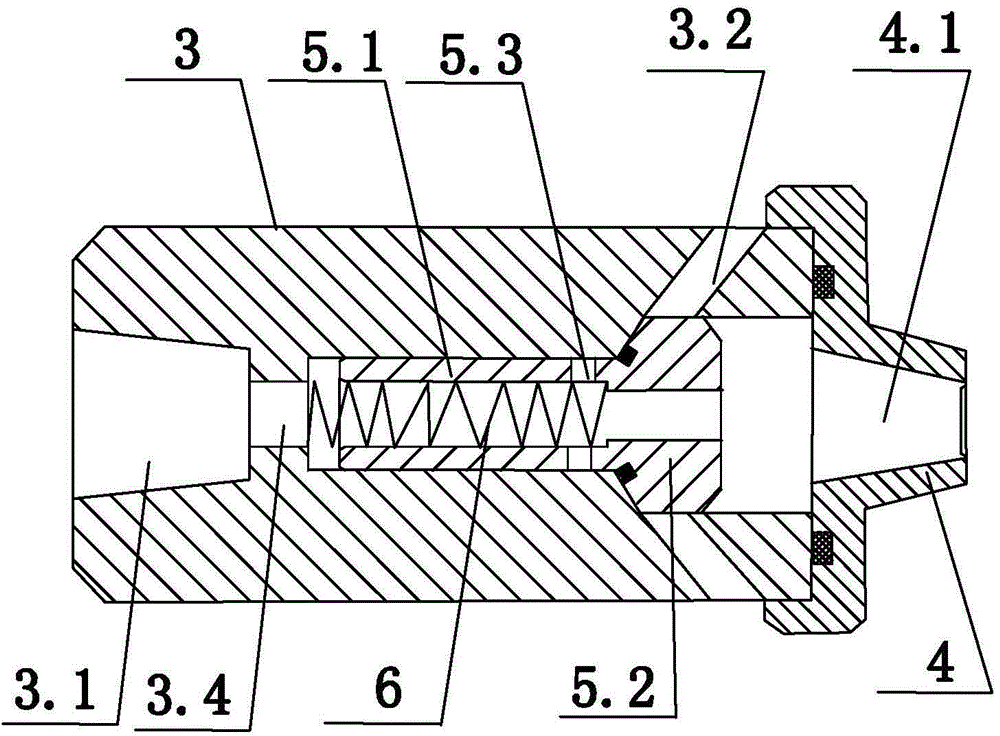

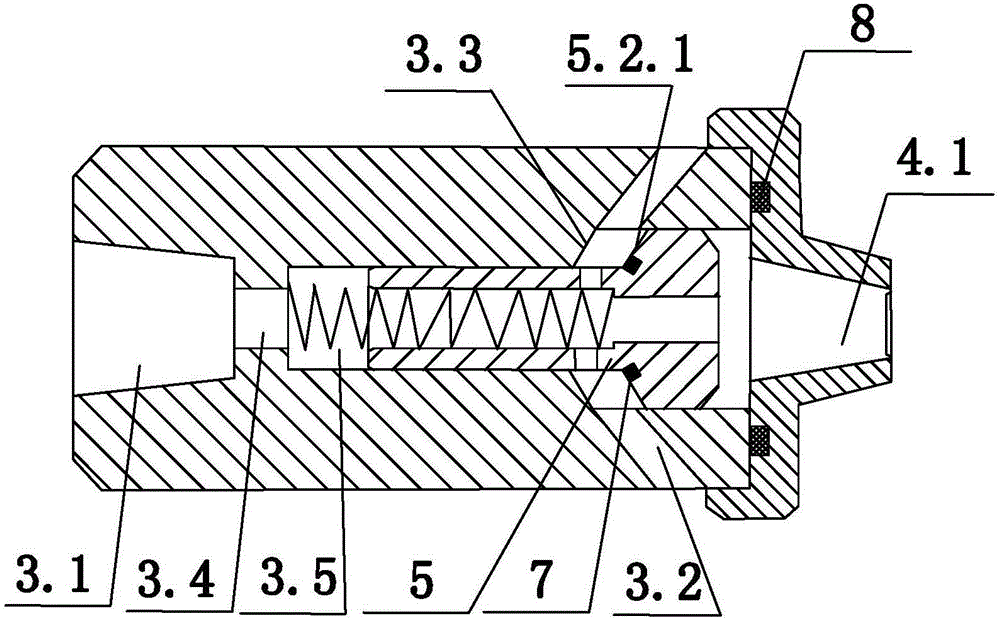

[0017] Such as Figure 1-3 As shown, a cutting fluid ejection device for OCV valves includes a three-jaw chuck 1 for clamping workpieces, and it also includes a liquid inlet pipe 2, a liquid outlet joint 3, a spring 6 and a valve core 5, The liquid inlet pipe 2 is connected to the rear end of the three-jaw chuck 1, and the liquid outlet joint 3 is arranged in the inner cavity of the three-jaw chuck 1 and placed close to the movable jaw. position, one end of the liquid outlet joint 3 is provided with a liquid inlet 3.1 for connecting with the liquid inlet pipe 2, and the liquid outlet joint 3 is provided with a hollow inner chamber 3.5 for slidingly fitting with the valve core 5, The valve core 5 is composed of a straight part 5.1 and a protruding part 5.2 in turn, and the wall of the hollow inner cavity 3.5 of the liquid outlet joint 3 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com