Polishing Expanded Foam Items

An article and foam technology, applied in the field of foam article processing, can solve the problems of increasing the workload of pre-formed foam parts and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

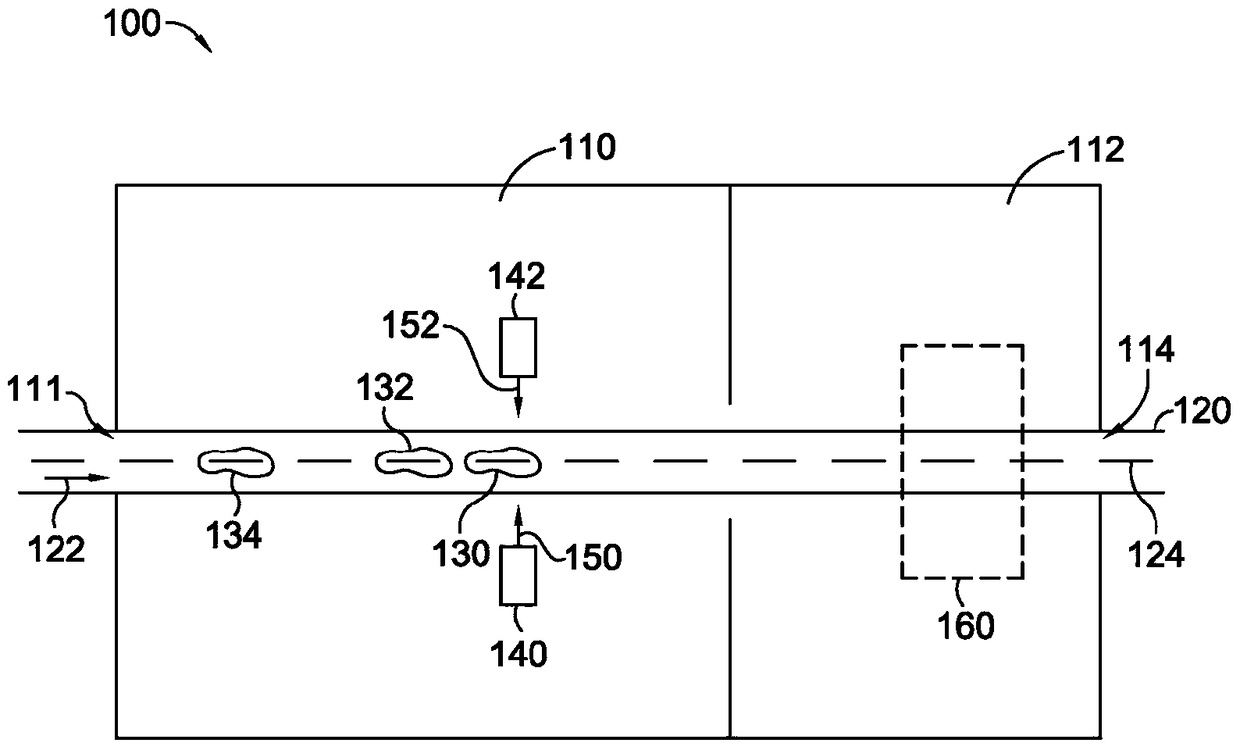

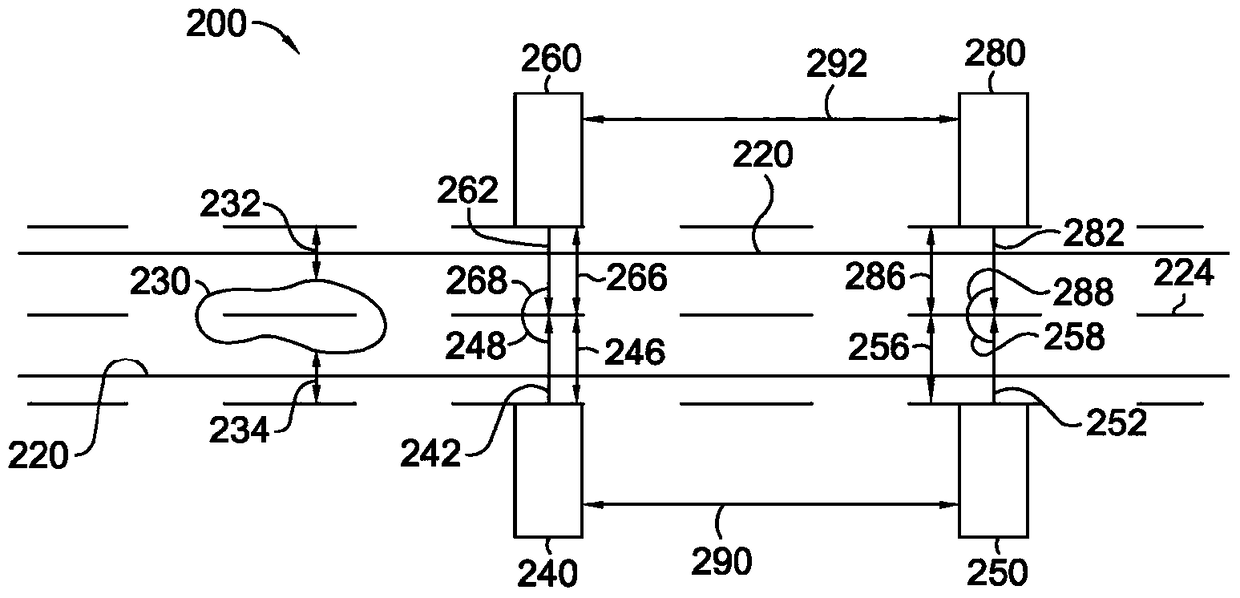

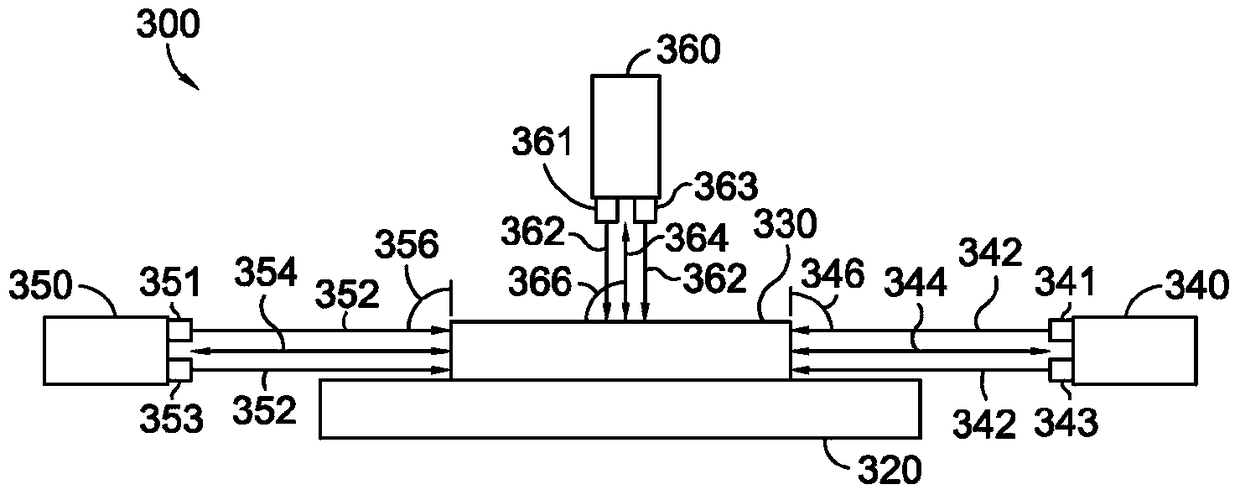

[0064] The present invention relates to the treatment of foam articles. Aspects of the invention relate to polishing an expanded foam item to remove at least a portion of the expanded foam item in preparation for further processing of the expanded foam item. One specific example of a product that typically utilizes foam is an article of footwear. Articles of footwear may include shoes, boots, sandals, and the like. For convenience, the term "shoe" is used herein as representative of an article of footwear. Shoes often utilize ethylene vinyl acetate ("EVA"), polyurethane, or other types of foam to provide cushioning (eg, impact attenuation) to the midsole or elsewhere in the shoe's construction. Although the invention is described in some instances with specific reference to foams such as EVA foam used in shoes, the invention may utilize other types of expanded foam materials and / or for use in products other than shoes.

[0065] According to an aspect of the invention, a met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com