Concrete continuous and uniform blanking device for pipe pile production

A technology for concrete and concrete mixers, applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of poor working environment, waste, and splashing out of workers, and achieve the effects of avoiding discontinuous blanking, eliminating potential safety hazards, and reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

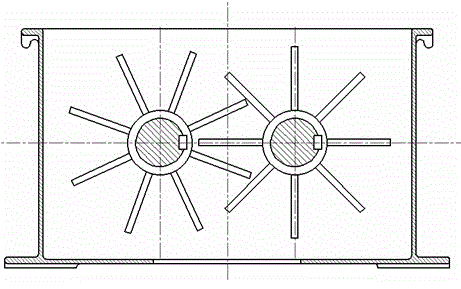

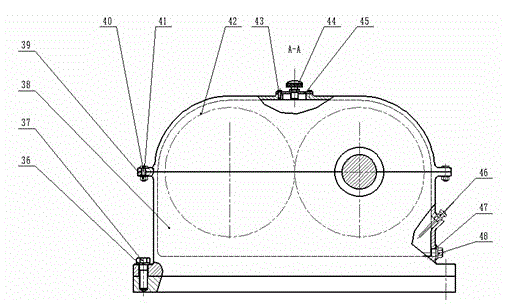

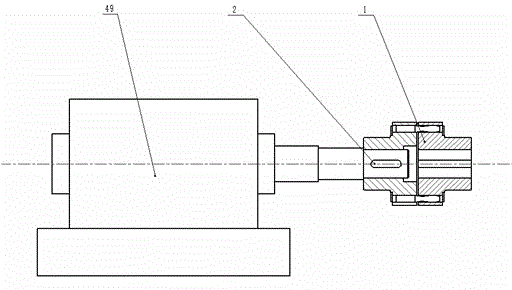

[0034]The device proposed by the present invention includes four parts: a power source, a driving shaft shaft assembly, a driven shaft shaft assembly and a feed bin. The power is provided by the reduction motor, the driving shaft shaft system obtains power from the power source, drives the blades on the driving shaft to rotate, and the driven shaft shaft system obtains power from the driving shaft through gears, drives the blades on the driven shaft to rotate, the driving shaft blades and The driven shaft blade rotates to mix the concrete, and the silo temporarily stores the concrete to provide space for the mixing. After the mixing is even, the concrete is discharged from the lower outlet of the silo. The details of each part will be introduced in detail in conjunction with the figure below.

[0035] combine Figure 5 and Figure 6 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com