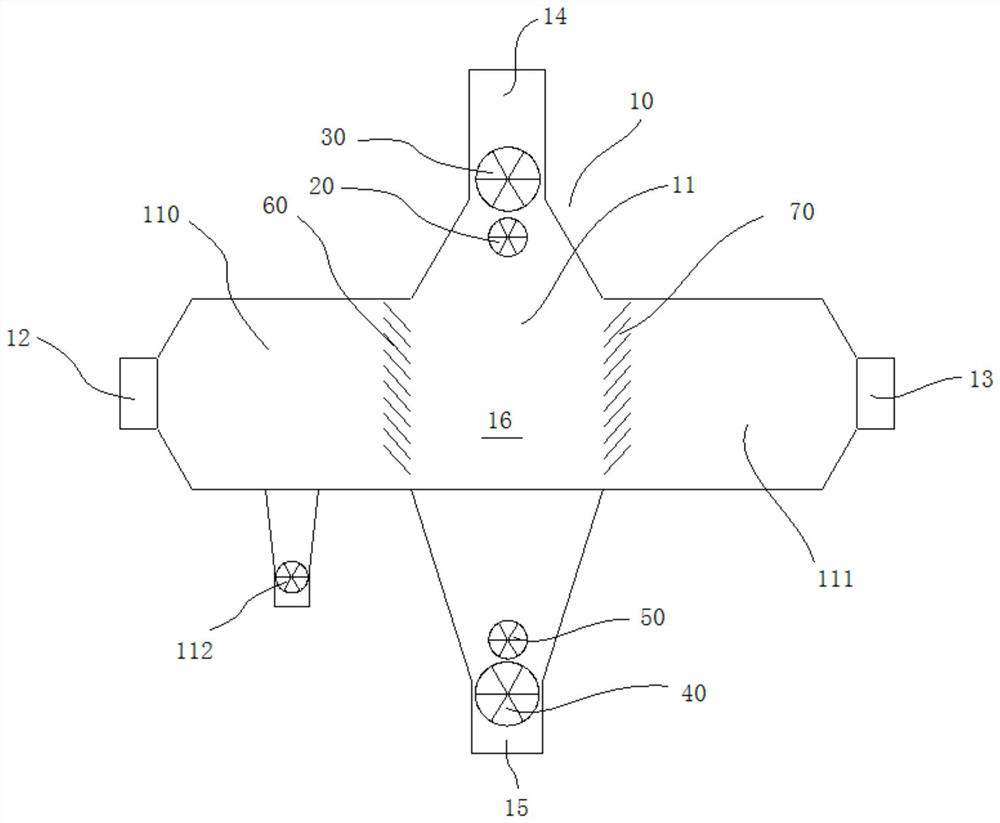

Granular bed dust removal device

A particle bed dust removal and internal cavity technology, applied in gas dust removal, dispersed particle filtration, dispersed particle separation, etc., can solve problems such as affecting the normal operation of the device and increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

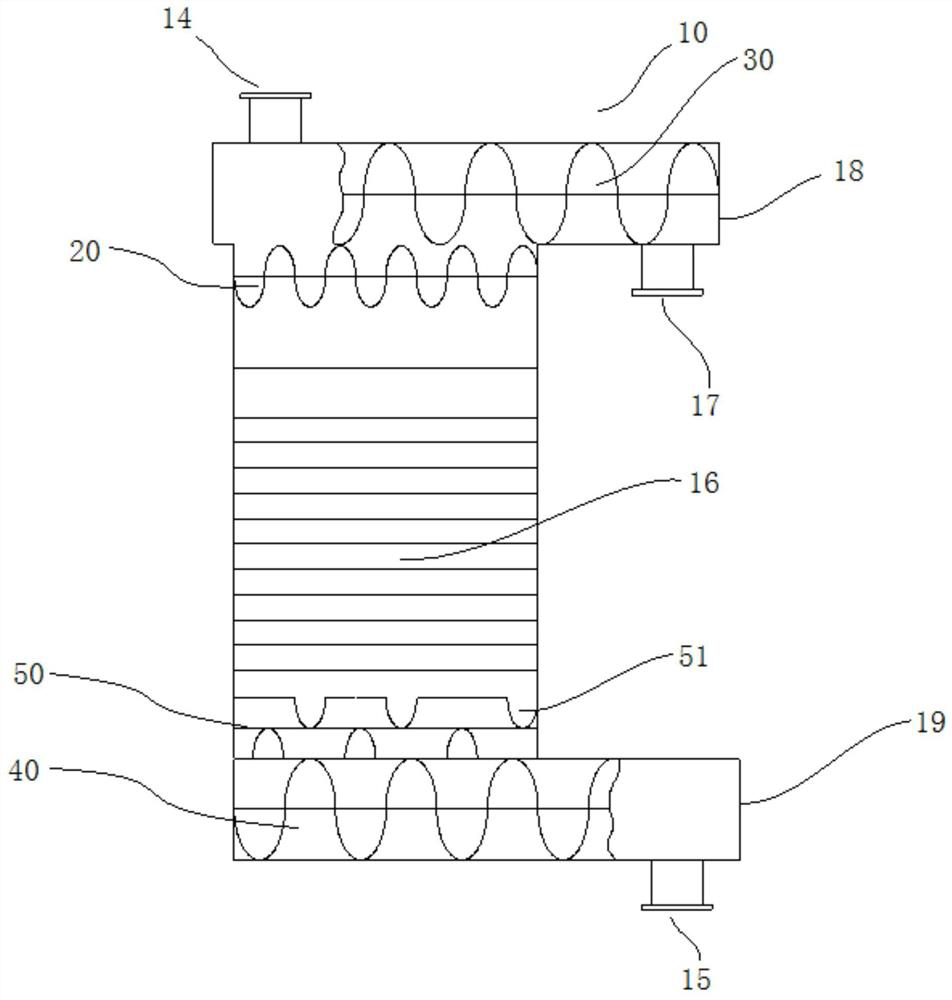

[0036] In this embodiment, ensure that the material conveying capacity of the auxiliary discharge screw conveying mechanism 50 is less than or equal to the material conveying capacity of the discharge screw 40, so that the material conveying capacity of the auxiliary discharge screw conveying mechanism 50 will not be too large As a result, the discharge screw 40 cannot deliver the auxiliary discharge screw mechanism 50 to the material near the dust removal material outlet 15 in time, resulting in material accumulation. Of course, it can be understood that, preferably, v1 / v2 is equal to V1 / V2, and at this time, the material conveying capacity of the auxiliary discharge screw conveying mechanism 50 matches the material conveying capacity of the discharge screw 40, reducing material accumulation. At the same time, the discharge screw 40 can output the material with the maximum conveying capacity.

[0037] And, specifically, as an easy-to-understand embodiment, the pitch of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com