Batching control method and system of concrete batching plant

A control method and concrete technology, applied in the direction of control devices, etc., can solve the problems of over-tolerance measurement and low batching efficiency, and achieve the effect of preventing over-tolerance and improving batching accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

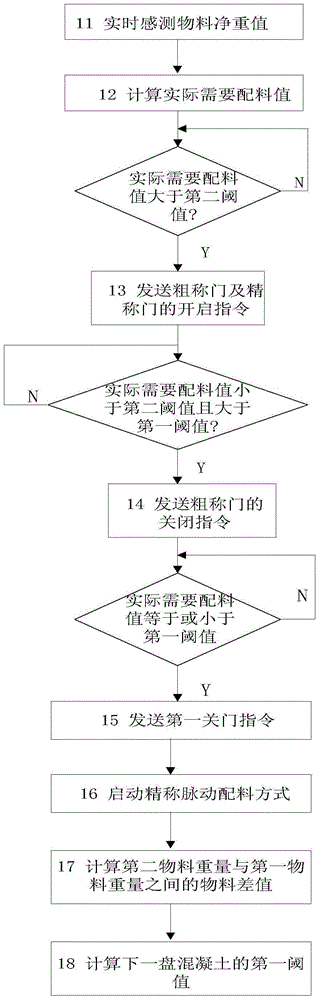

[0021] figure 1 The flow chart of the batching control method of the concrete batching plant provided by the embodiment of the present invention; figure 1 As shown, the batching control method of the concrete batching plant may include:

[0022] Step 11: Real-time sensing of the net weight value of the material in the weighing hopper of the concrete mixing plant.

[0023] Step 12: Calculate the difference between the preset target ingredient value and the net weight value of the material in real time to obtain the actual required ingredient value.

[0024] Then determine whether the actual required ingredient value is greater than the preset second threshold (can be understood as the mid-range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com