Forming method and cup body structure of paper cup

A molding method and a cup body technology are applied in the field of paper cups containing food or beverages, which can solve the problems of improper setting of outer paper layer fibers in the method of cutting and drawing materials, difficulty in folding and crimping of the cup mouth and curling, and insufficient structural strength of the cup body. , to achieve the effect of taking into account structural strength and durability, improving structural strength, flexibility and variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

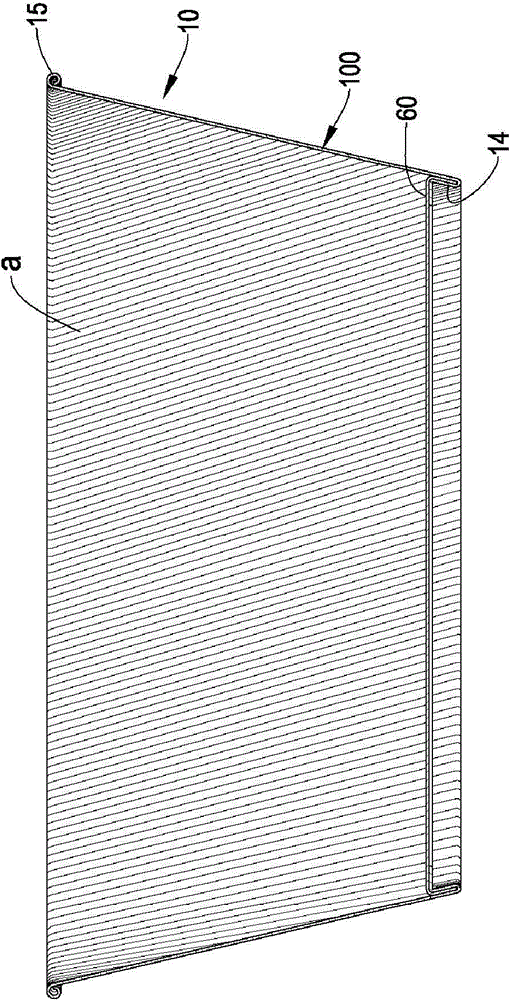

[0029] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings of the description and the preferred embodiments of the present invention.

[0030] see figure 1 and image 3 Shown, the forming step of the forming method of the paper cup that the present invention proposes comprises:

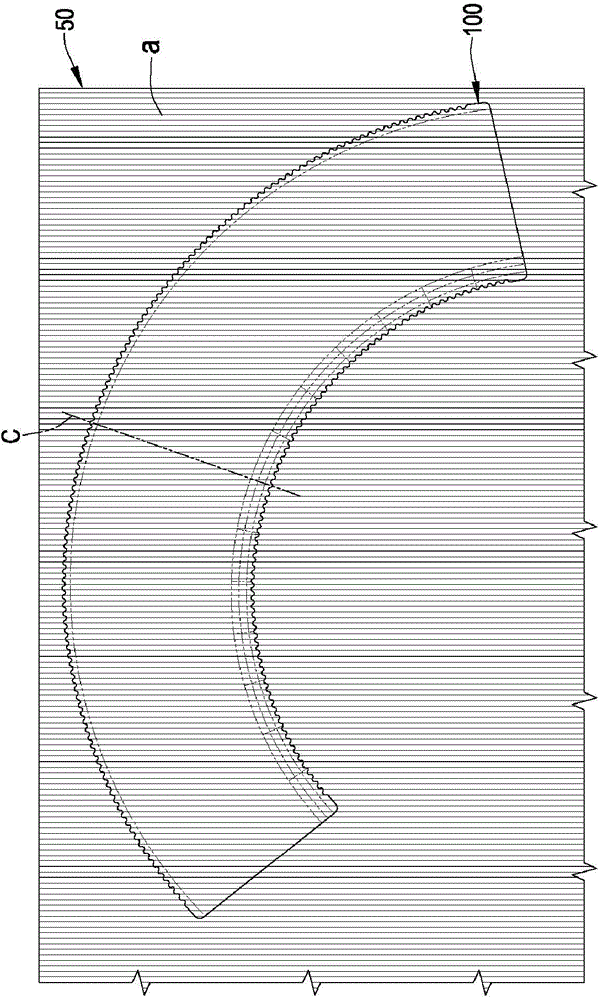

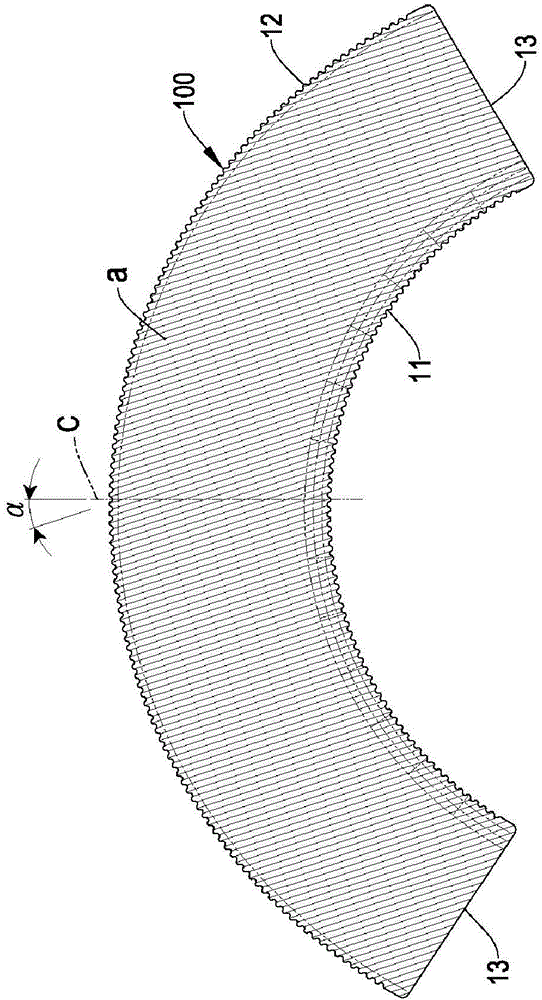

[0031] Select raw paper material: select a raw paper material 50, which includes two outer paper layers 51, an inner paper layer 52 disposed between the two outer paper layers 51, and a drape bonded to one of the outer paper layers. The waterproof membrane 53 of the paper layer 51, and the extending direction of the outer paper layer fibers a of the two outer paper layers 51 and the extending direction of the inner paper layer fibers b of the inner paper layer 52 are vertically staggered.

[0032] Typesetting die cutting: such as figure 1 As shown, using a fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com