Stitching Technology Reinforced Foam Sandwich Hat Type Reinforced Wall Panel Structure and Its Forming Method

A technology for reinforcing foam and reinforced wall panels is applied in the field of fiber composite material reinforcement, which can solve the problems of easy debonding of foam sandwiches, and achieve the effects of simple manufacturing process, strong bearing capacity and enhanced strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

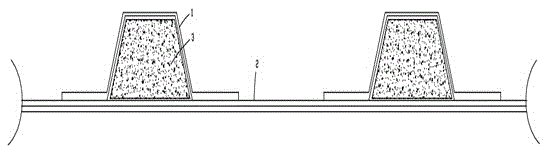

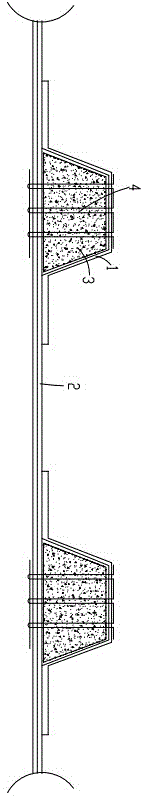

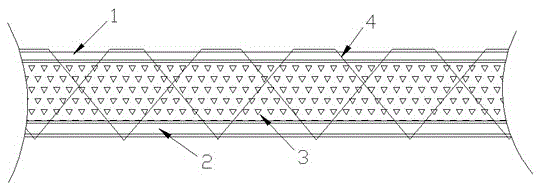

[0027] figure 1 Shown is the structure diagram of the prior art, figure 2 Shown is a schematic cross-sectional view of the structure of the present invention, image 3 Shown is a schematic cross-sectional view of the structure of the present invention along the direction of the ribs, where the reference signs are: hat-shaped rib 1, skin 2, foam core material 3, suture 4.

[0028] Such as Figure 1 to Figure 3 As shown, the stitching technology of the present invention enhances the foam sandwich hat-shaped stiffened wall panel structure, including a hat-shaped rib 1 and a skin 2. The hat-shaped rib 1 is fixed on the skin 2 and the hat-shaped rib 1 and the cover A cavity is formed between the skins 2 and the cavity is filled with a foam core material 3, wherein: the hat-shaped stiffened wall structure passes through the hat-shaped rib 1, the foam c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com