Electric roller

A technology of electric rollers and rollers, applied in the direction of conveyors, roller tables, conveyor objects, etc., can solve the problems of high noise, uneven operation, large volume, etc., and achieve the effect of reducing noise and convenient and accurate connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

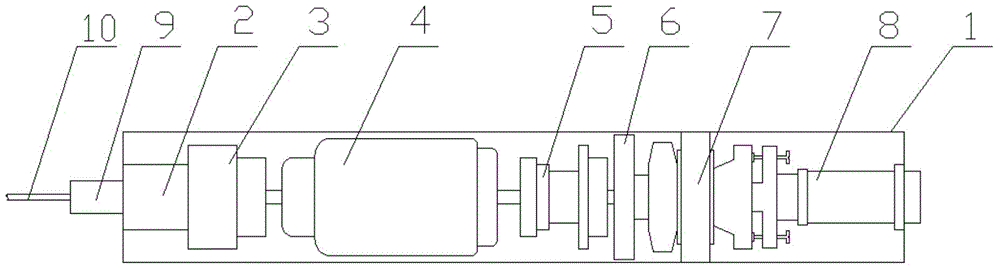

[0035] Such as figure 1 , figure 2 , image 3 An electric drum is shown, which includes a drum shell 1, a drum seat 2 is provided on one side of the drum shell 1, one side of the drum seat 2 is movably connected with the drum shell 1, and the other side of the drum seat 2 is provided with The stabilizing element 3 is movably connected with the drum seat 2, and the other side of the stabilizing element 3 is movably connected with the motor 4, and the other side of the motor 4 is provided with a gear set 5, which is connected with the motor 4 through a transmission shaft, and the gear set The other side of 5 is provided with a connector 6, which is movably connected with the gear set 5, and one side of the connector 6 is provided with a tensioning device 7, which is movably connected with the connector 6, and the drum shell 1 is provided with a roller seat 2. A cable sleeve 9 is arranged on the outside of the side, which is movably connected with the drum shell 1. The cable s...

Embodiment 2

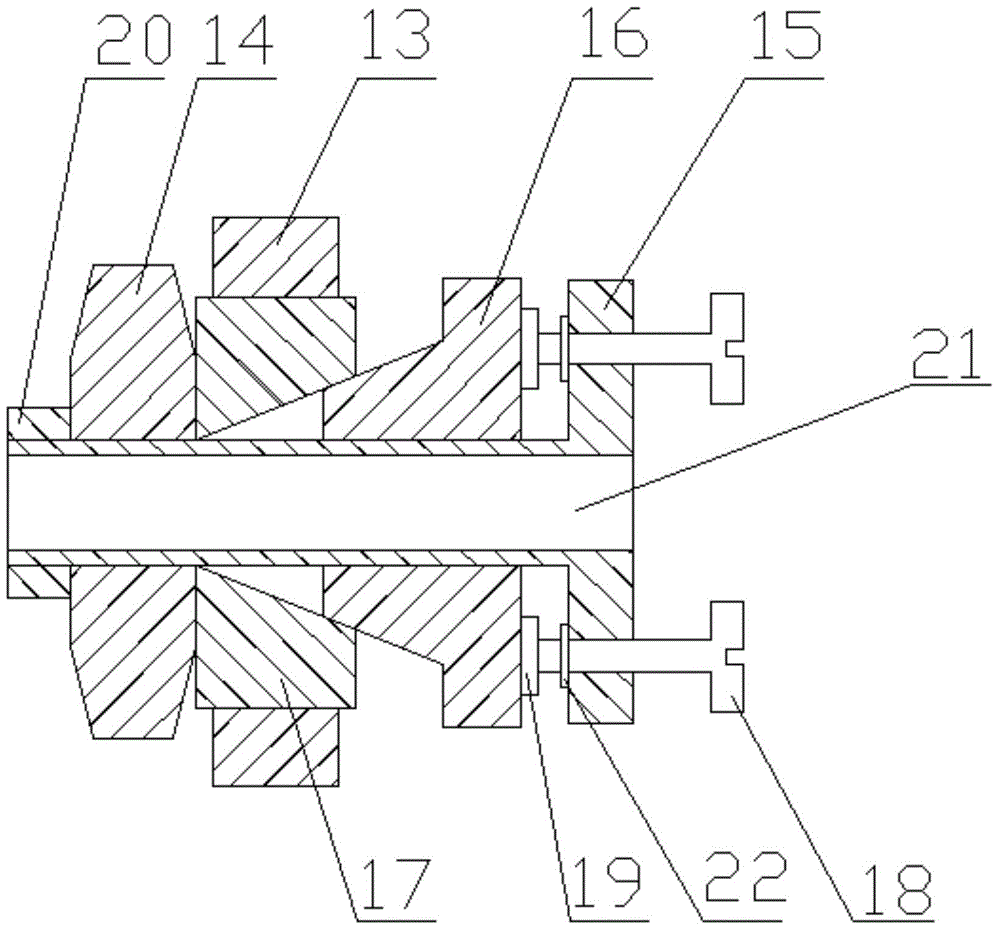

[0038] Such as figure 1 , Figure 4 , Figure 5 An electric drum is shown, which includes a drum shell 1, a drum seat 2 is provided on one side of the drum shell 1, one side of the drum seat 2 is movably connected with the drum shell 1, and the other side of the drum seat 2 is provided with The stabilizing element 3 is movably connected with the drum seat 2, and the other side of the stabilizing element 3 is movably connected with the motor 4, and the other side of the motor 4 is provided with a gear set 5, which is connected with the motor 4 through a transmission shaft, and the gear set The other side of 5 is provided with a connector 6, which is movably connected with the gear set 5, and one side of the connector 6 is provided with a tensioning device 7, which is movably connected with the connector 6, and the outside of the tensioning device 7 is provided with a rubber pad 13 , is movably connected with the tensioning device 7, and is closely attached to the drum shell 1...

Embodiment 3

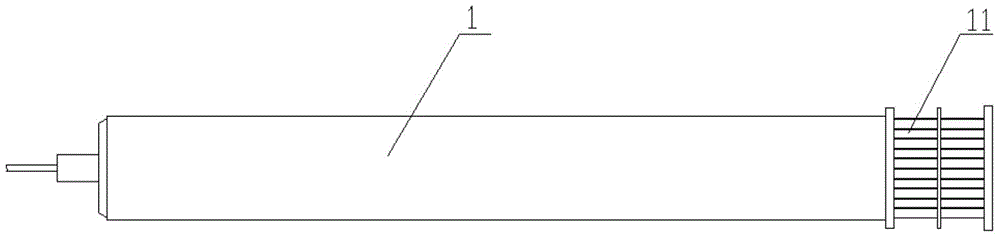

[0041] Such as Figure 6 , Figure 7 An electric drum is shown, which includes a drum shell 1, a drum seat 2 is provided on one side of the drum shell 1, one side of the drum seat 2 is movably connected with the drum shell 1, and the other side of the drum seat 2 is provided with The stabilizing element 3 is movably connected with the drum seat 2, and the other side of the stabilizing element 3 is movably connected with the motor 4, and the other side of the motor 4 is provided with a gear set 5, which is connected with the motor 4 through a transmission shaft, and the gear set The other side of 5 is provided with a connector 6, which is movably connected with the gear set 5, and one side of the connector 6 is provided with a tensioning device 7, which is movably connected with the connector 6, and the drum shell 1 is provided with a roller seat 2. A cable sleeve 9 is arranged on the outside of the side, which is movably connected with the drum shell 1. The cable sleeve 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com