Standby vertical upper and lower double hooks for discharge sling chain of trolley-type thermal treatment furnace charging tray

A trolley-type, furnace-hanging chain technology, applied in the direction of load hanging components, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

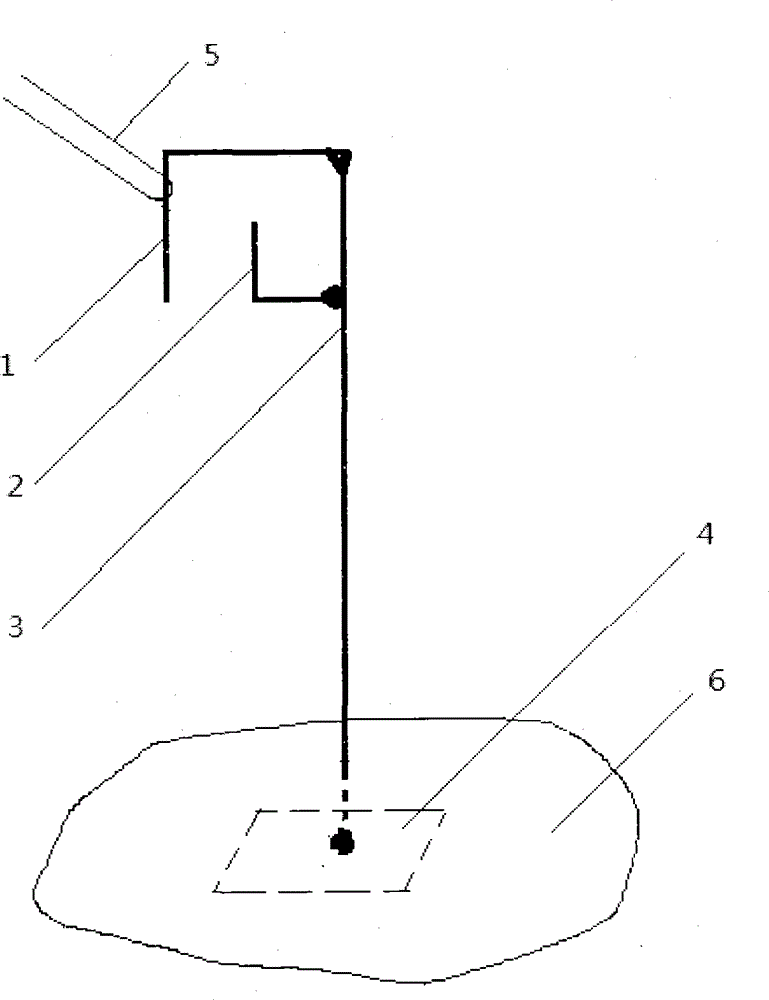

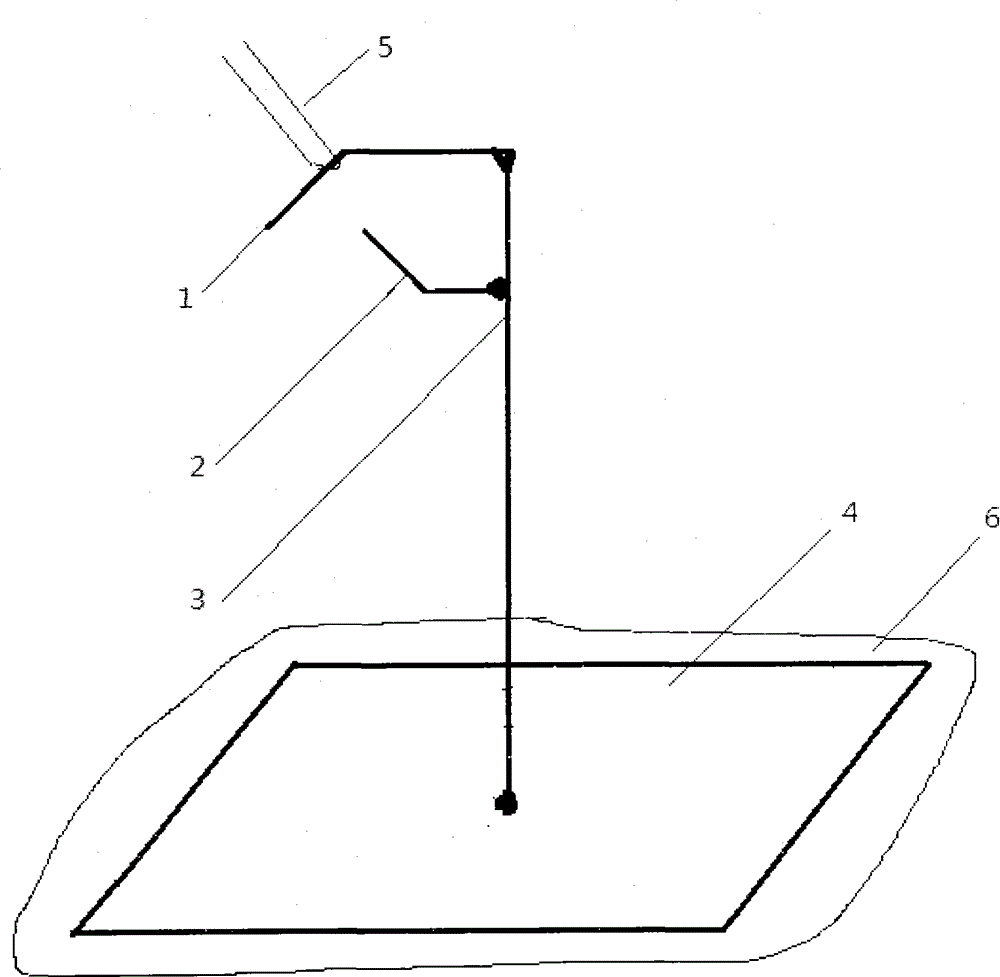

[0022] Embodiment 1: According to the above-mentioned technical solution of the present invention, a trolley-type heat treatment furnace material tray is discharged from the furnace, and the hanging chain is in place. The vertical upper and lower double hooks, its composition structure Such as figure 1 As shown: it is composed of double hook heads 1, 2, vertical rod 3, and chassis 4. The double hook heads 1, 2 are connected to the upper end of the vertical rod 3, and the vertical rod 3 is vertically connected to stand on the chassis 4; the double hook heads 1, 2 are composed of The lower finger outer hook 1 and the upper finger inner hook 2 are composed. The lower finger outer hook 1 is connected to the upper end of the vertical rod 3 with its hook point facing downward, and the upper finger inner hook 2 is connected to the upper part of the vertical rod 3 facing the side of the lower finger outer hook 1. , the hook tip faces upward, and its hook tip is located between the in...

Embodiment 2

[0023] Embodiment 2: According to the above-mentioned technical solution of the present invention, a trolley-type heat treatment furnace material tray is discharged from the furnace, and the hanging chain is waiting for the position. Vertical upper and lower double hooks, its composition structure Such as figure 1 As shown: it is composed of double hook heads 1, 2, vertical rod 3, and chassis 4. The double hook heads 1, 2 are connected to the upper end of the vertical rod 3, and the vertical rod 3 is vertically connected to stand on the chassis 4; the double hook heads 1, 2 are composed of The lower finger outer hook 1 and the upper finger inner hook 2 are composed. The lower finger outer hook 1 is connected to the upper end of the vertical rod 3 with its hook point facing downward, and the upper finger inner hook 2 is connected to the upper part of the vertical rod 3 facing the side of the lower finger outer hook 1. , the hook tip faces upward, and its hook tip is located be...

Embodiment 3

[0024] Embodiment 3: According to the above-mentioned technical solution of the present invention, a trolley-type heat-treated furnace material tray is discharged from the furnace, and the hanging chain is in place. Vertical upper and lower double hooks, the technical solutions such as its composition and structure are basically the same as Embodiment 2, the difference is: The angle between the tip of the outer hook under the finger and the horizontal plane is 30°; the angle between the tip of the inner hook on the finger and the upper part of the pole is 30° and it points upward and The above points to the direction of the outer hook. All the other are identical with embodiment two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com