A method for strengthening concrete structures

A technology of concrete structure and carbon fiber cloth, which is applied in the field of concrete, can solve the problems of high price, poor wettability, and poor fire resistance, and achieve the effects of enhanced shear resistance and stress cycle resistance, increased mechanical bonding, and improved reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

[0035] A carbon fiber cloth pretreatment method for concrete reinforcement, comprising the following steps:

[0036] (1) For treatment with anhydrous ethanol solution, soak the carbon fiber cloth with an anhydrous ethanol solution with a concentration of more than 99% for more than 24 hours; when soaking, the entire container should be sealed to prevent moisture in the air from entering the anhydrous ethanol and reduce the concentration of anhydrous ethanol , to ensure the soaking treatment effect;

[0037] (2) Alkaline solution treatment, prepare 40g / L sodium hydroxide solution, soak the carbon fiber cloth treated with absolute ethanol in the sodium hydroxide solution for more than 4 hours; this can effectively remove the organic matter and impurities on the surface of the carbon fiber cloth, and avoid It affects the follow-up reaction without damaging the carbon fiber cloth itself;

[0038] (3) Phosphate solution treatment, prepare a saturated ammonium dihydrogen phosphate ...

Embodiment ( 2

[0041] Embodiment (2) This specific embodiment is different from the specific embodiment (1) only in the soaked phosphate solution, and the rest are the same. The saturated phosphate solution in this specific embodiment is a saturated potassium dihydrogen phosphate solution with a concentration of 22.6 g / L.

Embodiment ( 3

[0042] Embodiment (3) This specific embodiment is different from the specific embodiment (1) only in the soaked phosphate solution, and the rest are the same. The saturated phosphate solution in this specific embodiment is a saturated sodium dihydrogen phosphate solution with a concentration of 86.9 g / L.

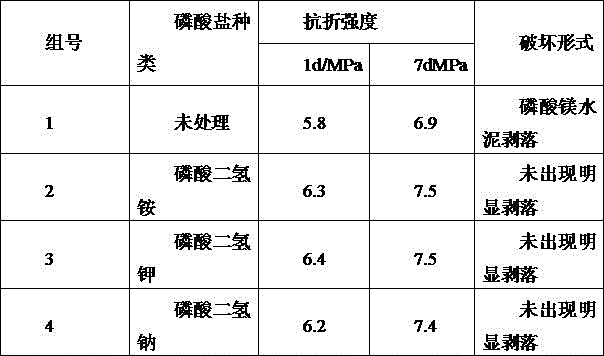

[0043] In order to further prove that the carbon fiber cloth obtained by the above pretreatment method can well generate magnesium ammonium phosphate hexahydrate between the fiber filaments inside the carbon fiber cloth, and improve the bonding strength between the carbon fiber cloth and the magnesium phosphate cement. The applicant used the distribution of carbon fiber cloth pretreated by the above three phosphate solutions and compounded it with magnesium phosphate cement made in the laboratory, and formed a 40mm×40mm×160mm test piece for testing. The size of the carbon fiber cloth was 40mm×160mm, and the carbon fiber cloth was arranged in The distance between the test pie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com