A kind of low temperature cracking resistant asphalt and preparation method thereof

A low-temperature, asphalt-resistant technology, applied in building thermal insulation materials, building components, buildings, etc., can solve problems such as poor desulfurization and degradation effect, scorch of rubber, affecting product performance, etc., to achieve small G*sinδ and production efficiency. High, short processing time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

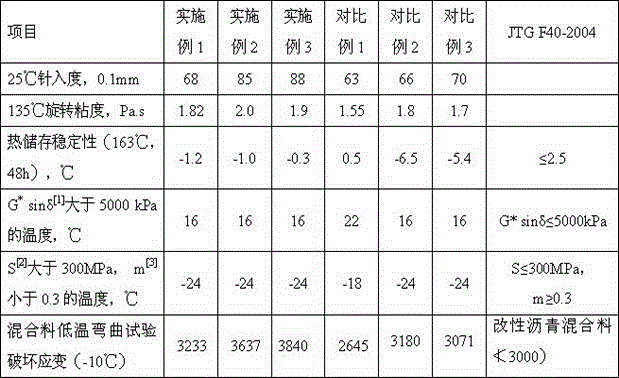

Examples

Embodiment 1

[0033] The ratio of the rubber particles of the anti-cracking asphalt composition is as follows:

[0034] 30 mesh rubber powder 89%

[0035] Furfural Extract Oil 8%

[0036] Organic boron surfactant SB-181 (Qingdao Siwei) 3%

[0037] The proportion of anti-crack bitumen composition is as follows:

[0038] Rubber particles 13%

[0039] Base bitumen 87%

[0040] The preparation process is as follows:

[0041] (1) Heat and melt furfural oil (8%) at 120°C, then add surfactant (3%) and stir evenly. The rubber powder (89%) is pre-soaked in oil by spraying. Then thin pass 110 times under the conditions of roll temperature 40°C and roll distance 0.8 mm, and then crushed into rubber particles with a diameter of 0.1-0.5 cm.

[0042] (2) Heat the Zhenhai base asphalt with a penetration (25°C) of 95 1 / 10mm to 165-175°C, add rubber particles and perform high-shear grinding for 10 minutes to obtain the crack-resistant asphalt composition of the present invention.

Embodiment 2

[0044] The ratio of the rubber particles of the anti-cracking asphalt composition is as follows:

[0045] 60 mesh rubber powder 85%

[0046] Minus 10% of oil extracted from the fourth line

[0047] Organic boron surfactant SPE-1 (Qingdao Siwei) 5%

[0048] The proportion of anti-crack bitumen composition is as follows:

[0049] Rubber particles 15%

[0050] Base bitumen 85%

[0051] The preparation process is as follows

[0052] (1) Heat and melt the minus four-line extraction oil (10%) at 120°C, then add surfactant (5%) and stir evenly. The rubber powder (85%) is pre-soaked in oil by spraying. Then thin pass 140 times under the conditions of roller temperature 60°C and roller distance 0.6mm, and then crushed into rubber particles with a diameter of 0.1-0.5cm.

[0053] (2) Heat Zhenhai base asphalt with a penetration (25°C) of 115 to 160°C-170°C, add 15% rubber particles and grind for 5 minutes under high shear to obtain a crack-resistant asphalt composition. The prope...

Embodiment 3

[0055] The composition formula is the same as that in Example 2, except that the rubber particles obtained after three-roll thin pass crushing are further subjected to microwave activation treatment. Treatment conditions: microwave power 1000W, microwave frequency 2000MHz, activation time 30 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com