Protecting structure for big-gradient stone slope

A stone slope and large slope technology, applied in infrastructure engineering, application, container cultivation, etc., can solve problems such as long time period, damage to natural ecological harmony, and inability to meet ecological harmony and unity, so as to reduce the difficulty of installation, The effect of simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

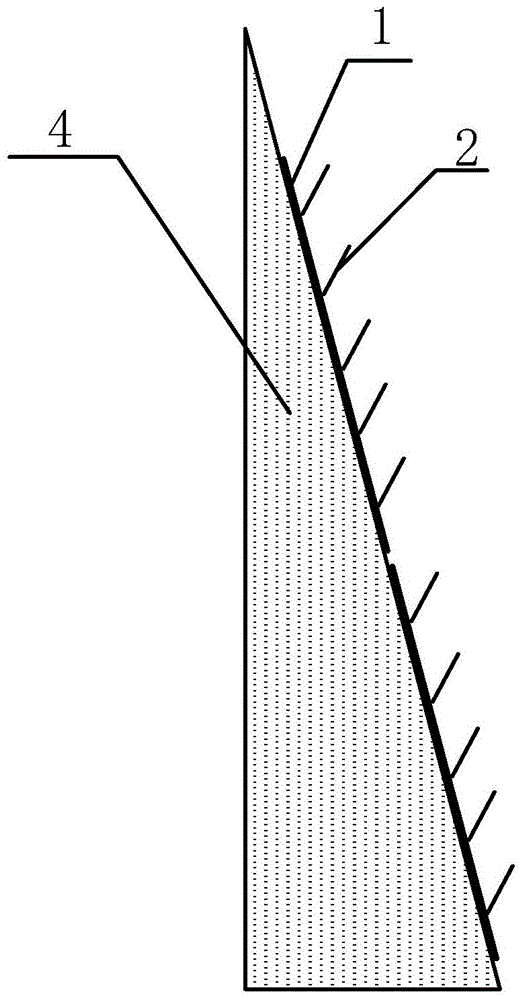

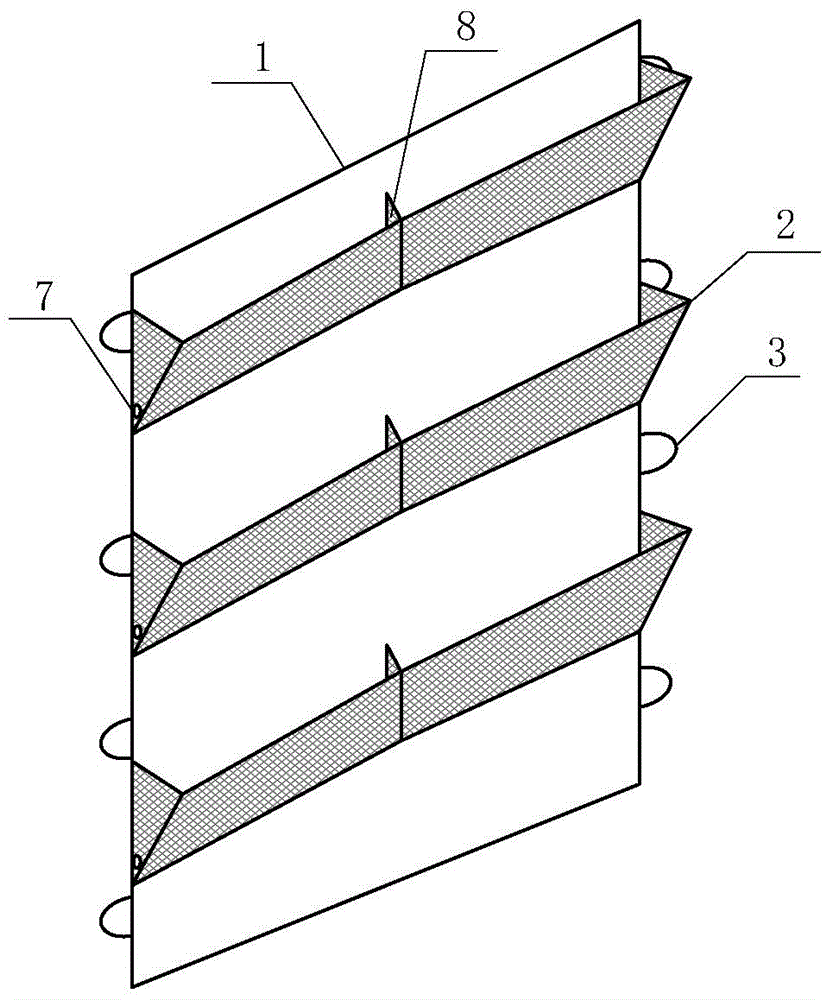

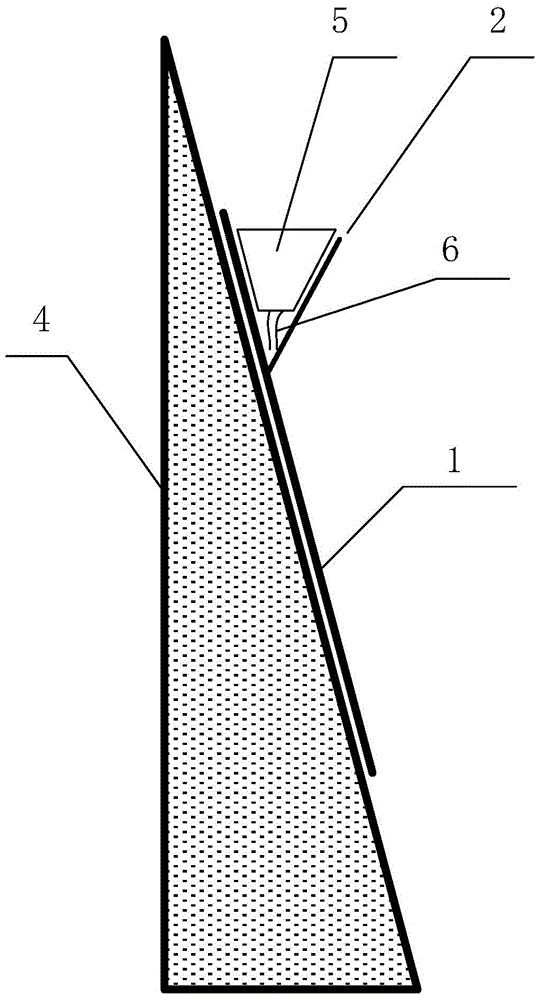

[0019] Such as figure 1 and 2 As shown, a nursing structure for a large slope stone slope of the present invention includes a plurality of nursing structure modules distributed in an array on the hillside, and each nursing structure module includes a planting board, a planting member, and anchors for fixing Hole and rectangular frame.

[0020] The planting board is connected by two sub-boards through the middle fixing board and fixed on the frame. The planes of the two sub-boards are at a certain angle to the plane of the frame, and the two sub-boards have a rising angle towards the middle fixing board. The planting board formed is in an inverted V shape; the ends of the two sub-boards facing the outside are closed, forming strip-shaped wedge-shaped grooves with the frame respectively; an overflow hole is opened in the middle of the closed end; the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com