Bending-resistant single-sided adhesive tape and preparation method thereof

A bending-resistant and adhesive tape technology, applied to adhesives, film/sheet adhesives, adhesive types, etc., can solve problems such as inability to fully rebound, improve experience comfort, facilitate operation, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

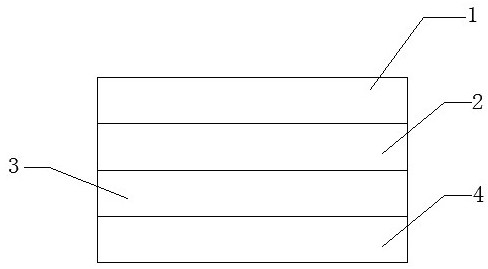

Image

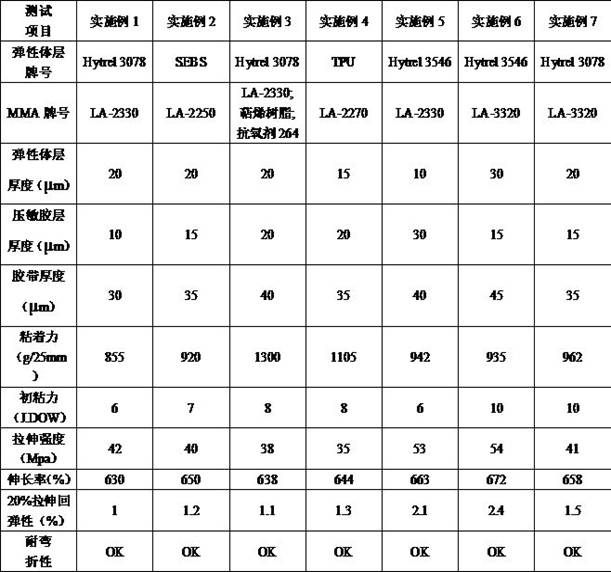

Examples

Embodiment 1

[0026] Add TPEE elastomer Hytrel 3078 to the dryer of No. 1 extruder, the drying temperature is 110°C, and the drying time is 4h; then add MMA elastomer LA-2330 (acrylate block copolymer) to No. 2 extruder In the drying machine of the machine, the drying temperature is 90°C, and the drying time is 4h.

[0027] The temperature of the No. 1 extruder is 220°C, and the speed of the extruder is 120rpm; the temperature of the No. 2 extruder is 220°C, the speed of the extruder is 100rpm, and the temperature of the die is 230°C. 20µm TPEE film and 10µm MMA composite film.

[0028] After the composite film is extruded through the die, the TPEE film layer is cast on the OPP film, the MMA pressure-sensitive adhesive layer is laminated with the silicone release film (organic silicon OPP film) layer, and the bottom film layer-20μmTPEE is obtained after cooling and winding. -10µm MMA -Four layers of anti-bending single-sided adhesive tape with release film layer.

Embodiment 2

[0030] Add SEBS elastomer to the dryer of No. 1 extruder, the drying temperature is 110°C, and the drying time is 4h; then add MMA elastomer LA-2250 (acrylate block copolymer) to the dryer of No. 2 extruder In the dryer, the drying temperature is 90° C., and the drying time is 4 hours.

[0031] The temperature of the No. 1 extruder is 210°C, and the speed of the extruder is 100rpm; the temperature of the No. 2 extruder is 200°C, the speed of the extruder is 120rpm, and the temperature of the die head is 200°C. 20µm SEBS film and 15µm MMA composite film.

[0032] After the composite film is extruded through the die, the TPEE film layer is cast on the matte OPP film, the MMA pressure-sensitive adhesive layer is laminated with the silicone release film (organic silicon OPP film), and the bottom film layer is obtained after cooling and winding -20µmSEBS-15µmMMA -Four layers of anti-bending single-sided adhesive tape with release film layer.

Embodiment 3

[0034] Add TPEE elastomer Hytrel 3078 into the dryer of No. 1 extruder, the drying temperature is 110°C, and the drying time is 4h; then MMA elastomer LA-2330 (acrylic acid) mixed with terpene resin and antioxidant 264 Ester block copolymer) into the dryer of No. 2 extruder, the drying temperature is 90°C, and the drying time is 4h.

[0035] The temperature of the No. 1 extruder is 240°C, and the speed of the extruder is 150rpm; the temperature of the No. 2 extruder is 210°C, the speed of the extruder is 130rpm, and the temperature of the die head is 220°C. 20µm TPEE film and 20µm MMA composite film.

[0036] After the composite film is extruded through the die, the TPEE film layer is cast on the PE coated paper, the MMA pressure-sensitive adhesive layer is laminated with the silicone release film (organic silicon PET film), and the bottom film layer is obtained after cooling and winding. -20µmTPEE-20µmMMA -Four layers of anti-bending single-sided tape with release film layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com