A variable-hole row-spacing impingement film cooling structure for the nozzle wall

A film cooling and wall surface technology, which is applied to jet propulsion devices, machines/engines, etc., can solve the problems of small drop, the infrared radiation suppression effect needs to be improved, and the overall cooling of the wall surface temperature has not been realized, so as to improve the impact cooling efficiency and enhance the Wall-adhesive effect, uniform cooling distribution effect on the wall surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

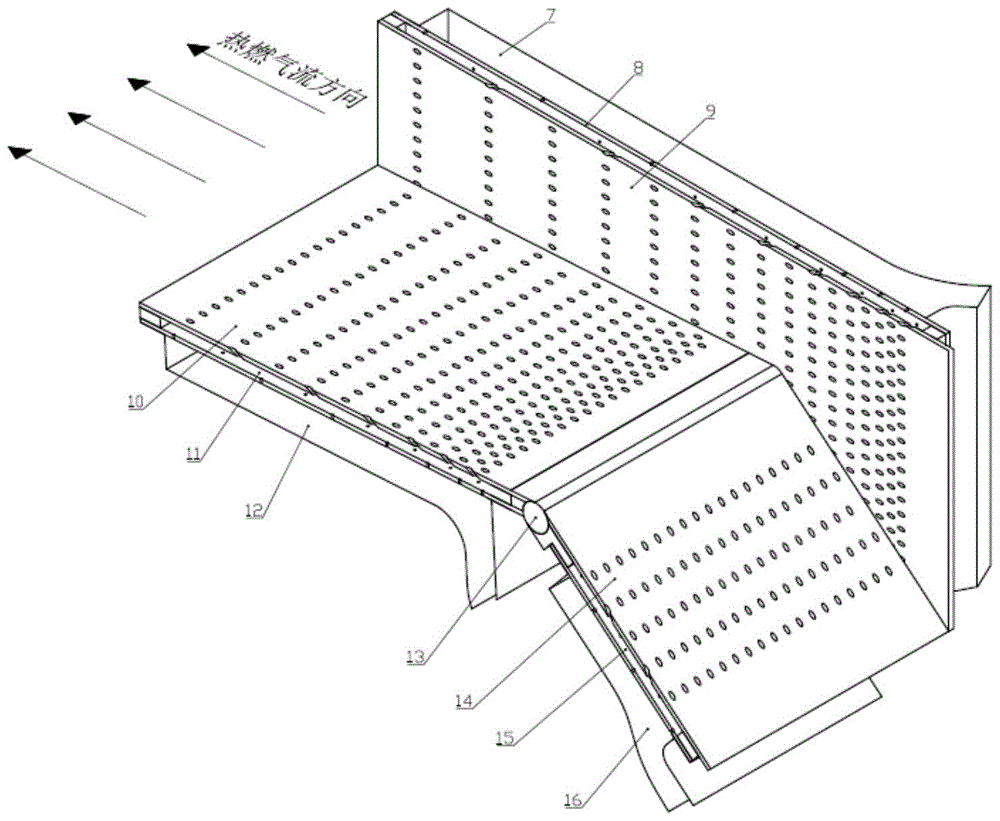

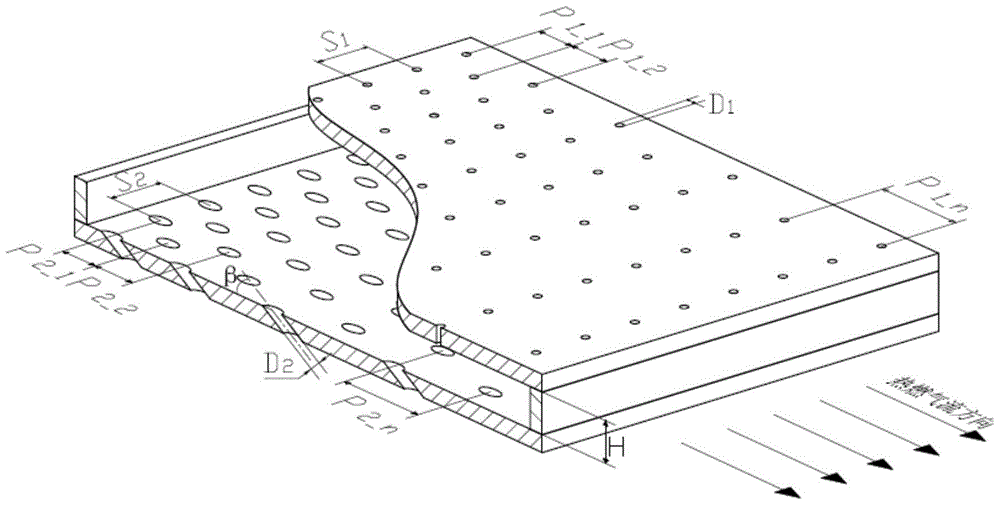

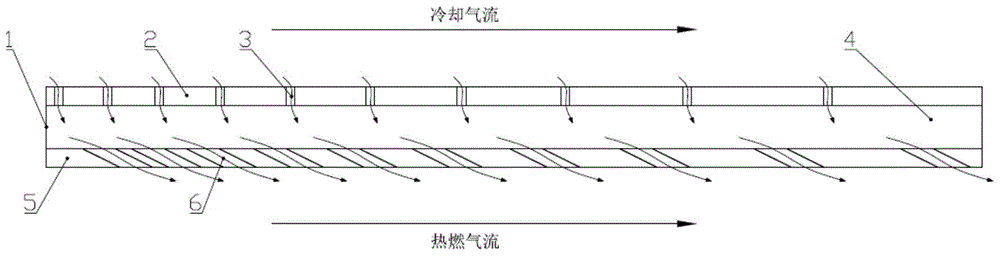

[0026] Please refer to Figure 1 to Figure 3 As shown, the impingement film cooling structure with variable hole row pitch applied to the nozzle wall of the present invention mainly includes an end wall 1 , an outer side wall 2 and an inner side wall 5 . The end wall 1 connects the outer wall 2 and the inner wall 5 to form a cooling chamber 4, the outer wall 2 is provided with an impact hole 3, and the inner wall 5 is provided with a gas film hole 6; the impact hole 3 is a circular hole with a diameter of D. 1 , which is consistent with the normal direction of the outer wall surface; the air film hole 6 is a circular hole with a diameter of D 2 , forms a certain deflection angle β with the normal direction of the inner wall surface, and the deflection direction is consistent with the hot gas flow direction; the row spacing of the impact holes 3 is den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com