Online assembly aging integrated wire of intelligent toilet and operation technology thereof

A technology for smart toilets and smart toilet lids, applied in assembly machines, water supply devices, manufacturing tools, etc., can solve the problems of complicated product labeling process, reduce enterprise production efficiency, increase labor costs, etc., achieve stable and reliable test results, and avoid damage and damage, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

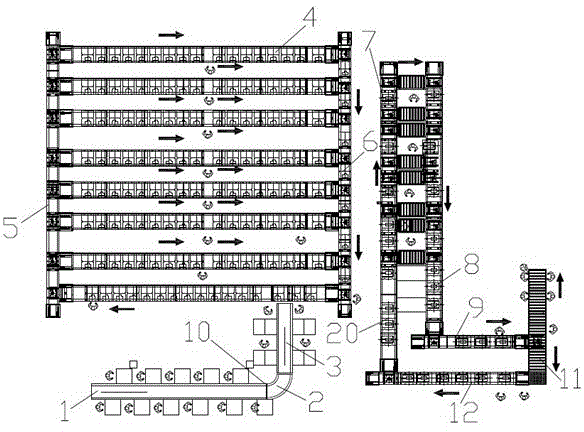

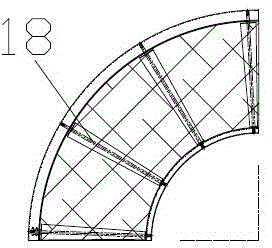

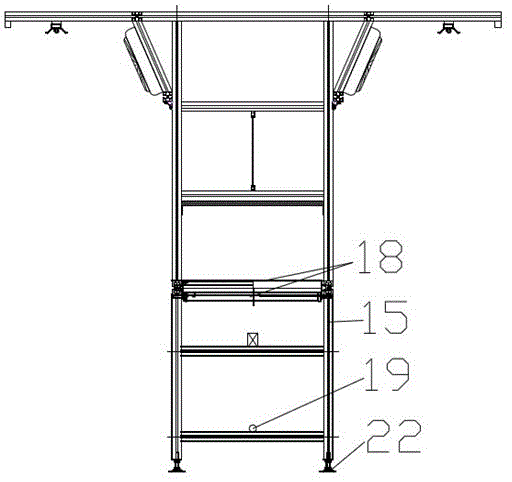

[0034] Such as Figure 1-7 As shown, an on-line assembly and aging integrated line of an intelligent toilet, the integrated line mainly includes an assembly line, an aging test line, a transmission line and a packaging line 11, and the described assembly line includes the first assembly line for assembling the intelligent toilet cover line 10 and the second assembly line 20 that assembles the toilet body and the intelligent toilet cover together; the described water test aging line includes the first aging test water line 4 that carries out high-pressure aging and water test detection on the intelligent toilet cover and the toilet Body and smart toilet cover are assembled together to form the second aging water test line 7 for the whole set of toilets to carry out power-on test water test; the transmission line includes sending the assembled smart toilet cover to the first aging test line 4 for aging The first transmission line 5 for water testing and the second transmission l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com