Winding displacement lifting type fireproof roller shutter

A fire-proof rolling shutter and lift-type technology, which is applied in the direction of fire doors, door/window protection devices, shutters/movable grilles, etc., can solve the problems of increased weight and deflection of rolling bearings, affecting the operation of rolling shutters, etc., reaching the application range broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

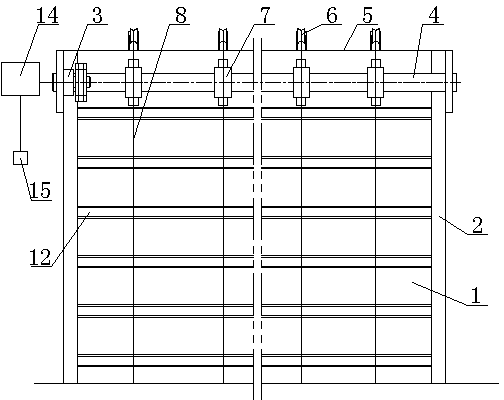

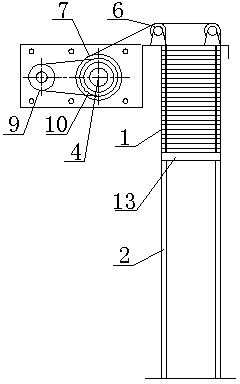

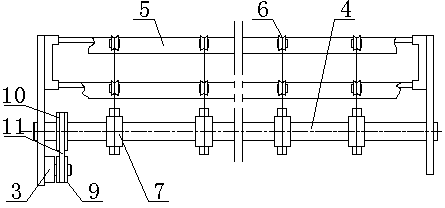

[0023] Such as Figure 1-Figure 3 As shown, the cable lifting type fire shutter is composed of a curtain surface 1, a lifting mechanism and a guide rail 2. Wherein, the lifting mechanism consists of a fireproof electric hoist 3, a reel 4, a transmission mechanism connected between the fireproof electric hoist 3 and the reel 4, a universal coupling connected between adjacent reels 4, A plurality of fixed pulleys 6 arranged on the top bracket 5 of the doorway of the building, a plurality of sheaves 7 arranged on the reel 4 corresponding to the fixed pulleys 6, and a plurality of horizontally evenly arranged on the curtain surface 1 Lifting is made up of wire rope 8, and in the present embodiment, adopts a reel 4, thereby does not need to be provided with universal coupling. The transmission mechanism is a chain transmission mechanism, which is composed of sprocket I9, sprocket II10 and chain 11 connected between the sprockets I, II9, and 10 respectively arranged on the fireproo...

Embodiment 2

[0029] Such as Figure 4 As shown, the cable lifting type fire shutter is composed of a curtain surface 1, a lifting mechanism and a guide rail 2. Wherein, the lifting mechanism is composed of a fireproof electric hoist 3, a reel 4, a transmission mechanism connected between the fireproof electric hoist 3 and the reel 4, and a universal coupling 16 connected between adjacent reels 4. , a plurality of fixed pulleys 6 arranged on the top bracket 5 of the door opening of the building, a plurality of rope pulleys 7 arranged on the reel 4 corresponding to the fixed pulleys 6, and a plurality of pulleys 7 evenly arranged on the curtain surface 1 in the transverse direction In this embodiment, the installation environment is U-shaped, so three reels 4 are used, which are respectively reels I, II and III, and two universal couplings 16 are arranged in total. The transmission mechanism is a chain transmission mechanism, which is composed of sprocket I9, sprocket II10 and chain 11 conn...

Embodiment 3

[0031] Such as Figure 5 As shown, the cable lifting type fire shutter is composed of a curtain surface 1, a lifting mechanism and a guide rail 2. Wherein, the lifting mechanism is composed of a fireproof electric hoist 3, a reel 4, a transmission mechanism connected between the fireproof electric hoist 3 and the reel 4, and a universal coupling 16 connected between adjacent reels 4. , a plurality of fixed pulleys 6 arranged on the top bracket 5 of the door opening of the building, a plurality of rope pulleys 7 arranged on the reel 4 corresponding to the fixed pulleys 6, and a plurality of pulleys 7 evenly arranged on the curtain surface 1 in the transverse direction In this embodiment, the installation environment is curved, and a plurality of reels 4 are used, and two universal couplings 16 are respectively arranged between the two reels 4. The transmission mechanism is a chain transmission mechanism, which is composed of sprocket I9, sprocket II10 respectively arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com