Reciprocating impact mining part of guide screw fastening impact rack of mining machine

A lead screw and guide rod technology, applied in the field of machinery, can solve the problems of shock resistance, poor vibration resistance, less dust, and increased maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

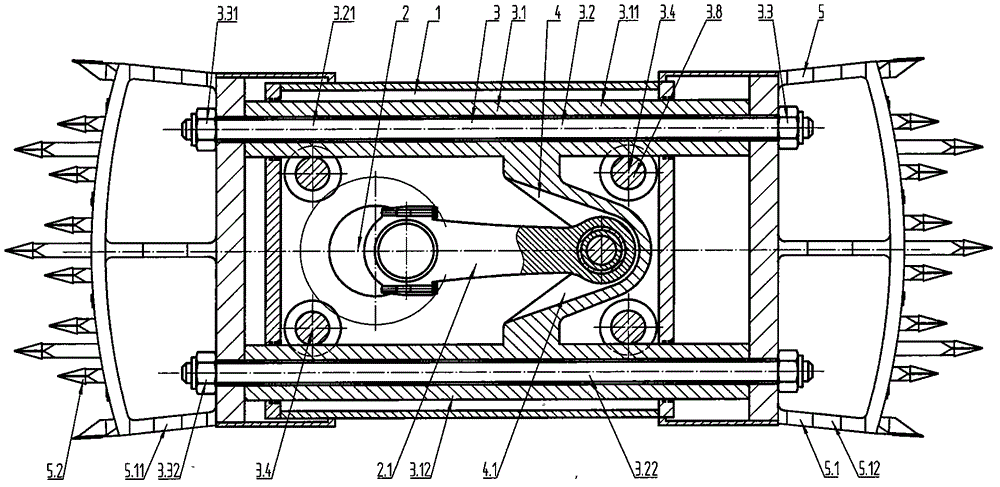

[0073] like figure 1As shown, a mining machine lead screw tightens the impact frame to reciprocate the impact on the mining part, including a box body 1, a power driver 2, a screw guide 3, a guide connector 4, an impact power source 6, and an impact head 5. The impact head 5 includes punching gear holder 5.1 and punching gear 5.2, etc., punching gear holder 5.1 includes front punching gear holder 5.11 and rear punching gear holder 5.12, etc., guide connector 4, power driver 2, etc. are arranged in box body 1, screw guide 3 includes guide rod 3.1, guide screw rod 3.2 and guide nut 3.3, etc., guide rod 3.1 includes guide rod A3.11, guide rod B3.12, etc., guide rod A3.11, guide rod B3.12 are set up and down and / or left and right , lead screw 3.2 includes lead screw A3.21, lead screw B3.22, etc., guide nut 3.3 includes guide nut A3.31, guide nut B3.32, etc., guide connector 4 includes guide rod connector 4.1, etc., guide rod Connector 4.1 is connected with guide rod A3.11, guide ...

Embodiment 2

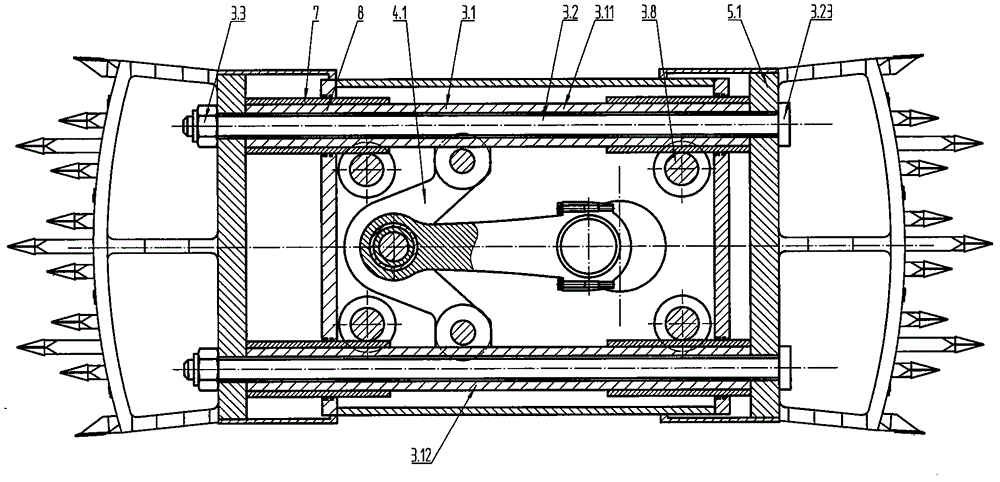

[0076] like figure 2 As shown, one end of the guide screw 3.2 is provided with a positioning boss 3.23, and the other end is installed with a guide nut 3.3. The guide screw 3.2 passes through the guide rod 3.1, the guide rod connector 4.1, and the punching seat 5.1. One end is positioned with the positioning boss 3.23, and the other end Lock with the guide nut 3.3, the positioning boss 3.23 is connected separately or integrally with the guide screw 3.2, and one end of the guide screw 3.2 is the positioning boss 3.23, reducing the number of guide nuts 3.3 used, reducing the number of guide screws 3.2 and guide nuts 3.3 Cooperate with the probability that the guide nut 3.3 is easy to loosen, enhance the tension force, and make a guide screw 3.2 fasten the guide rod 3.1, the guide rod connector 4.1, the punch seat 5.1, etc., so that the stability and structural strength of the impact frame are higher than multiple Bolted shock mounts.

[0077] The guide rod A3.11 and the guide ...

Embodiment 3

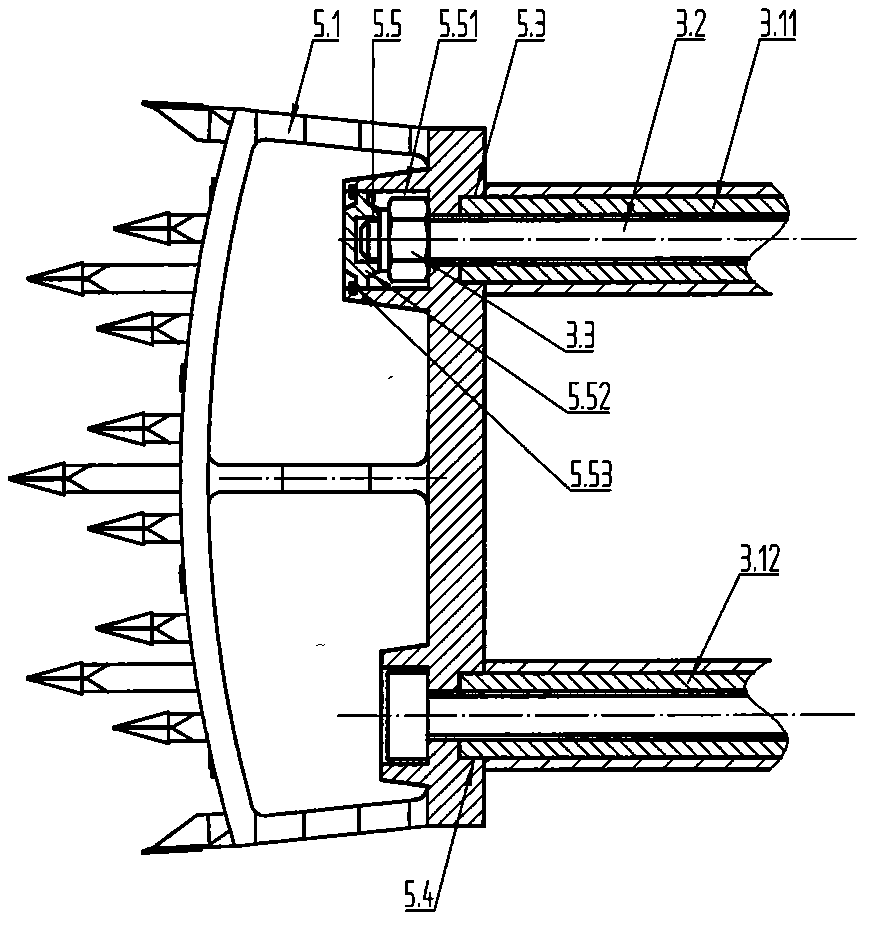

[0081] like image 3 As shown, the punch seat 5.1 includes the guide rod positioning hole A5.3 and the guide rod positioning hole B5.4, etc., one end of the guide rod A3.11 is set in the guide rod positioning hole A5.3, and one end of the guide rod B3.12 is set in the In guide rod positioning hole B5.4, guide rod A3.11 cooperates with guide rod positioning hole A5.3 and / or guide rod B3.12 cooperates with guide rod positioning hole B5.4, and guide rod A3.11, guide rod B3.12 The righting strength of the counter-tooth gear seat 5.1.

[0082] Punch tooth seat 5.1 is provided with easy-to-disassemble protection guide nut mechanism 5.5 etc., easy-to-remove protection guide nut mechanism 5.5 comprises tooth seat guide nut hole 5.51, guide nut shield 5.52 and shield connector 5.53 etc., guide screw rod 3.2 ends are arranged on In the guide nut hole 5.51 of the tooth seat, the guide nut 3.3 is fastened to the guide screw 3.2 in the guide nut hole 5.51 of the tooth seat, and the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com