Thinned fan

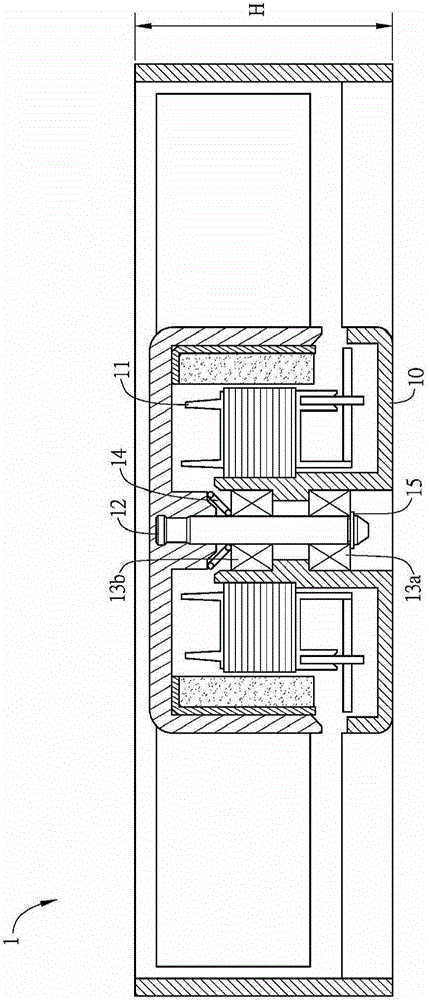

A technology of thin fans and fan blades, applied in the direction of non-variable pumps, pump devices, machines/engines, etc., can solve problems such as difficult to realize fan structure 1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

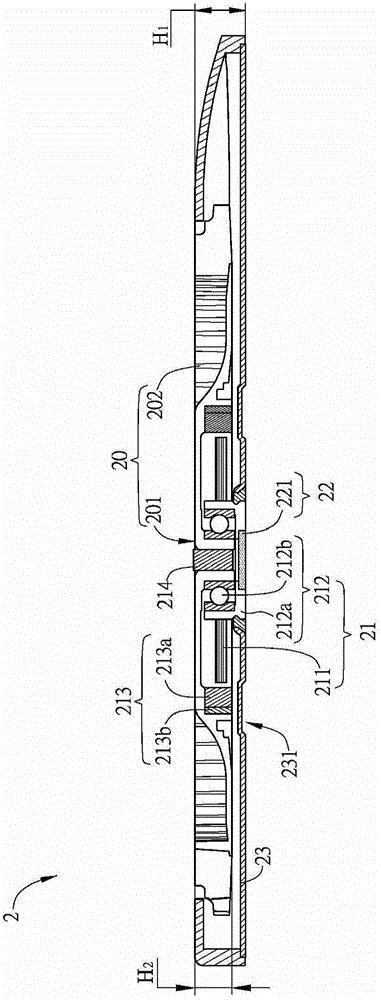

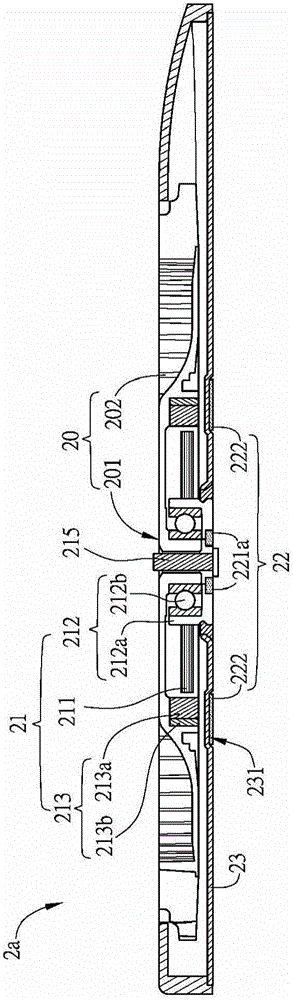

[0050] A thin fan according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference symbols.

[0051] First, please refer to figure 2 , figure 2 It is a schematic cross-sectional view of the first embodiment of the thin fan of the present invention.

[0052] The thin fan 2 of the present invention includes an impeller 20 and a motor 21 . Moreover, the thin fan 2 of this embodiment may further include at least one magnetic component 22 . Wherein, at least one magnetic component 22 in this embodiment includes at least a first magnetic component 221 .

[0053] The impeller 20 has a hub 201 and a blade structure 202 . The blade structure 202 is disposed around the hub 201, wherein the hub 201 has a through hole, and the through hole can be a hollow cylinder. The fan blade structure 202 and the hub 201 illustrated in this figure can be integrated into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com