Light-weight stepless gearbox

A technology of continuously variable gearbox and gearbox body, applied in the direction of gearbox, energy industry, fluid transmission device, etc., can solve the problems of poor stability, high cost, difference in wind power generation speed, etc., and achieve the effect of micro-precision adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

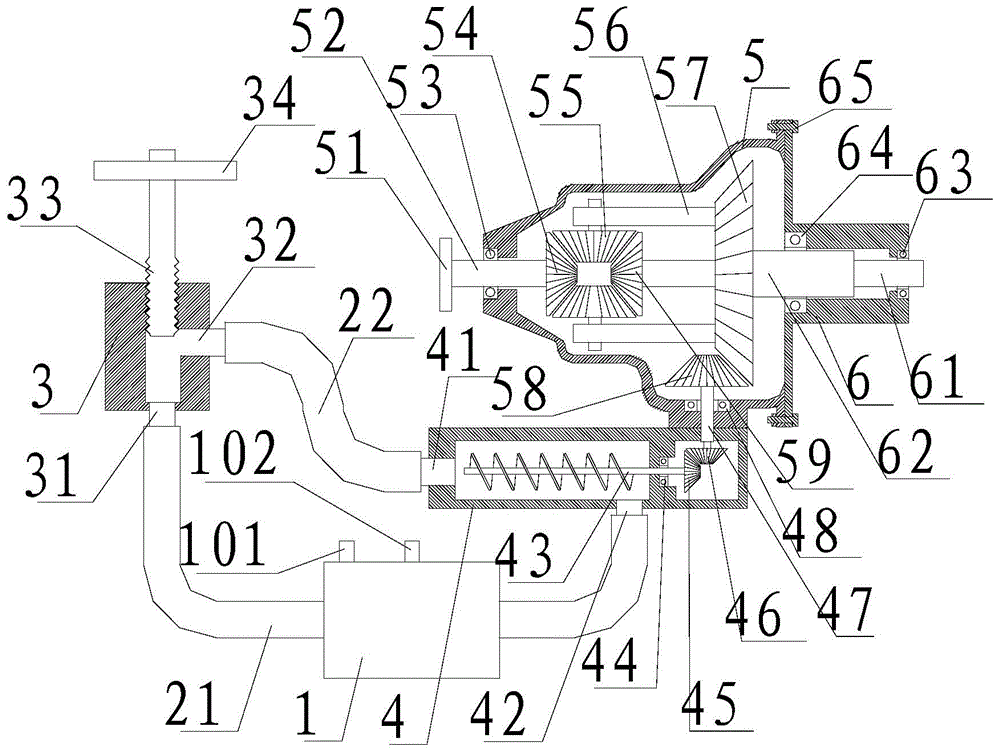

[0018] refer to figure 1 , a light-weight continuously variable transmission of the present invention, comprising a flow control valve 3, a colloidal power pump 4, a transmission case 5 and a transmission cover 6, and the transmission case 5 and the transmission cover 6 are mounted together through fixing bolts 65 , a power input shaft 61 is installed on the transmission cover 6, a speed-regulating power output shaft 62 is installed on the power input shaft 61, a power input gear 59 is installed on the power input shaft 61, and the speed-regulating power A speed regulating power output gear 57 is installed on the output shaft 62, a speed regulating gear bracket 56 is installed on the speed regulating power output gear 57, a speed regulating gear 55 is installed on the speed regulating gear bracket 56, and the gearbox body A third bearing 53 is installed on the 5, a power output shaft 52 is installed on the third bearing 53, a power output gear 54 is installed on the power outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com