High-speed hydraulic oil pump ground driving structure and driving method thereof

A technology of hydraulic oil pump and driving structure, which is applied to liquid fuel engines, pumps, pump components, etc., and achieves the effects of simple process requirements, good speed characteristics, and improved speed regulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

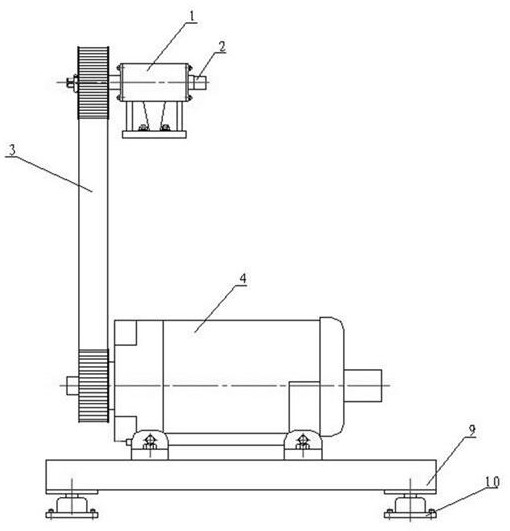

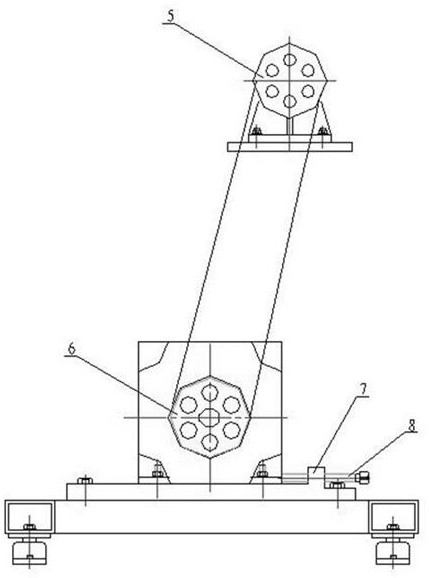

[0026]Refer to the attachmentfigure 1 ,2, A high-speed hydraulic oil pump floor drive structure, the high-speed rotating shaft 2 on the high-speed spindle lubrication box 1 is connected to the synchronous tooth strip 3, the other end of the synchronous toothed belt 3 is connected to the DC motor 4 through the motor speed disk 6, the DC motor 4 passes the motor The adjustment frame 7 is mounted on the mounting frame 9.

[0027]The lower end of the mounting frame 9 is mounted with a damping block 10. One end of the high-speed rotary shaft 2 has a fuel pump speed disk 5. The motor regulator 7 is fixed to the mounting frame 9 by the motor conditioning screw 8.

Embodiment 2

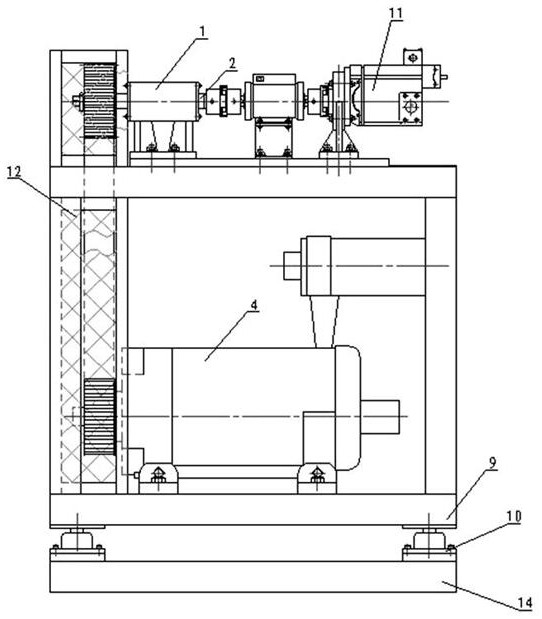

[0029]Refer to the attachmentimage 3 ,4The aircraft hydraulic oil pump provides power to the aircraft hydraulic system. At 1500 ~ 4200R / min speed, the mutual settlement of landing, the flight task profile, etc., the hydraulic system load has a sharp change, and the drive system of the hydraulic oil pump A large influence, the rotational speed changes dramatically, and the impact is eliminated in the ground simulation test of the aircraft hydraulic system.

[0030]The aircraft hydraulic pump 11 is a constant voltage variable plunger pump, a rated pressure 21MPa, a maximum flow of 92.5 L / min, its maximum output power:

[0031]

[0032]Oil pump input power:

[0033]

[0034]In order to ensure that the drive motor has a certain load stiffness on the load oil pump, the drive motor power is pressed:

[0035]PElectricity = KPEntered= 1.5x36 = 54KW

[0036]Where: K - power margin coefficient is generally selected from 1.5 to 2.0, and 1.5 is taken here.

[0037]Therefore, the motor output power is selected from...

Embodiment 3

[0048]A high-speed hydraulic oil pump ground driving method, the method modulates the input current of the DC motor 4, thereby changing the output speed of the DC motor, transmitting the power of the DC motor 4 by the synchronous tooth strip 3, changing the oil pump speed disk 5, motor speed The diameter of the disk 6 is thereby adjusted the transfer speed of the DC motor to the hydraulic oil pump;

[0049]Pump speed disk 5 Connect high speed shaft 2, high speed rotary shaft 2 connecting hydraulic oil pump, high-speed spindle lubrication box 1 to lubricate high-speed rotary shaft 2;

[0050]The DC motor 4 is mounted on the motor regulator 7, moving the DC motor via the motor conditioning screw 8 to adjust the preload of the synchronous toothed belt 3 to ensure that it is not slipping;

[0051]Motor adjustment frame 7, the DC motor 4 is mounted on the mounting frame 9, and the mounting frame 9 is shocked through the entire system through the damper block 10.

[0052] Further, the drive garace 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com