Vertically arranged indexing table mechanism in automation control

An automatic control and vertical arrangement technology, applied in the direction of transmission devices, fluid transmission devices, mechanical equipment, etc., can solve the problems of wasting manpower, fatigue, and difficult transmission in place accurately, and achieve convenient expansion, high degree of automation, and automatic transmission effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

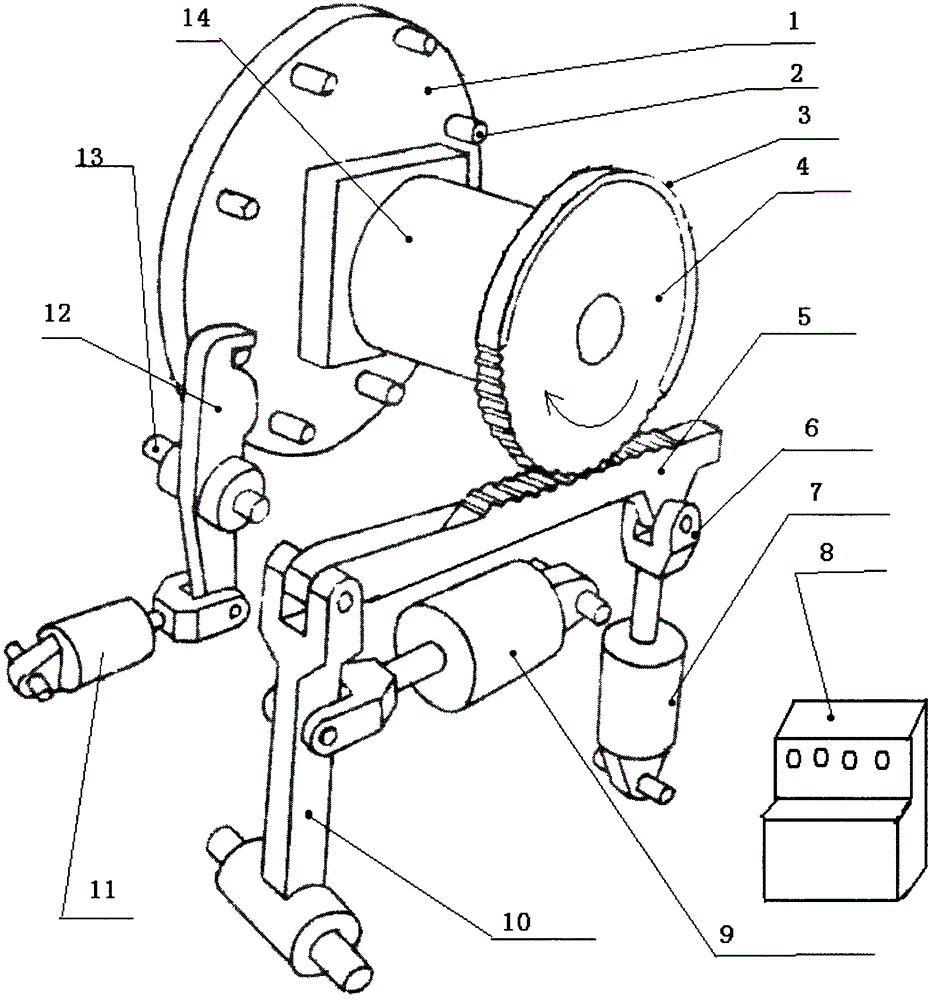

[0020] like figure 1 As shown, when the index plate 1 needs to be indexed, the piston rod of the cylinder C11 stretches out, and since the fixed shaft 13 is fixed on the frame, the positioning rod 12 becomes a lever. When the lower end of positioning rod 12 is pushed to the right. When the upper end of positioning rod 12 must move to the left, at this moment positioning pin 2 separates from positioning rod 12, and index plate 1 just can rotate freely. Now the piston rod of the cylinder B9 stretches out, pushes the connecting rod 10, the lower end of the connecting rod 10 is fixed, and the upper end of the connecting rod 10 pulls the rack 5 to move, thereby driving the gear 4 to turn through a certain angle, and the center of the gear 4 is equipped with a rotating shaft. The rotating shaft is supported by the bearing seat 14, and the rotating shaft drives the indexing plate 1 to turn over an indexing angle. After the indexing is completed, the piston rod of the cylinder C11 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com