Transverse-mounting type pneumatic piston executing mechanism of angular travel adjusting valve

A technology of pneumatic pistons and actuators, which is applied in the direction of valve operation/release devices, valve devices, engine components, etc., and can solve the problems of poor control accuracy of quarter-stroke regulating valves, larger volumes of actuators, and large accumulated errors. Achieve the effect of improving precision, compact structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

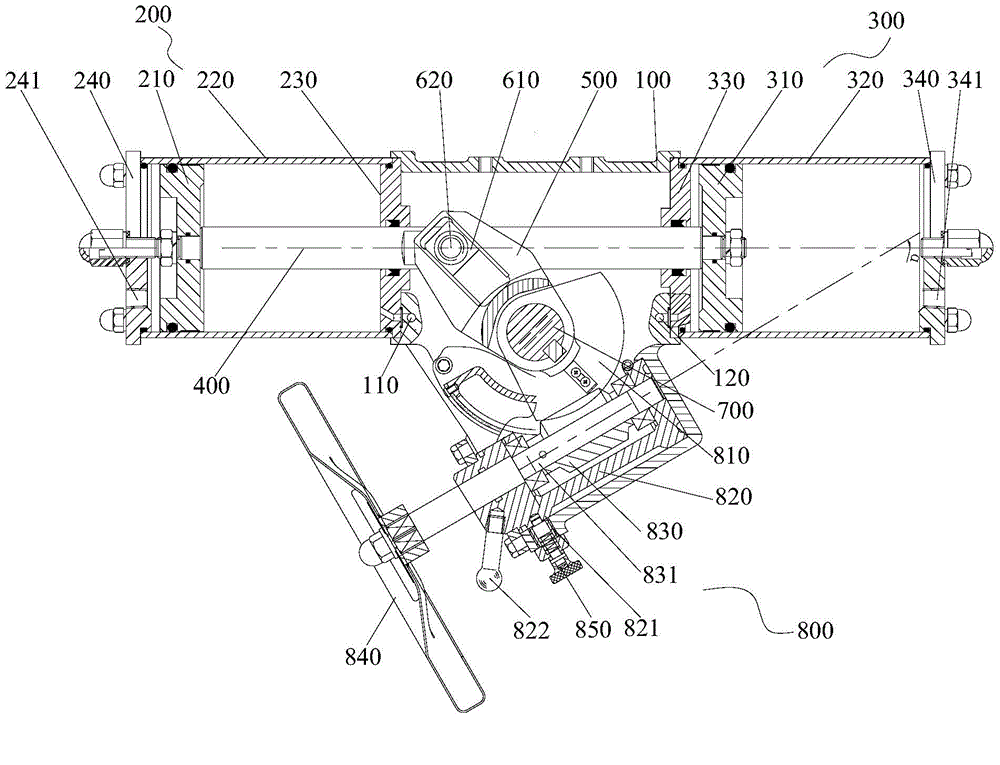

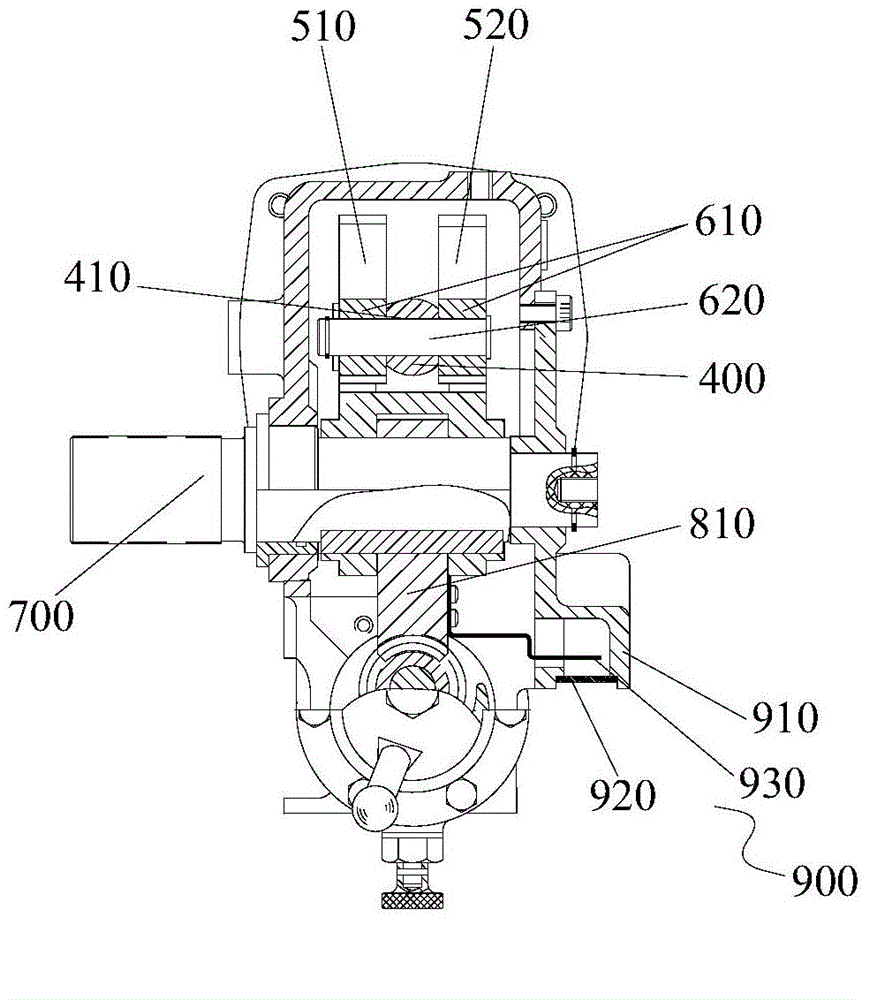

[0074] Such as figure 1 and figure 2 As shown, the horizontal-mounted pneumatic piston actuator of the angular stroke regulating valve in this embodiment includes: a box body 100, a first cylinder 200, a second cylinder 300, a piston rod 400, a shift fork 500, and two slider bodies 610, slider pin 620 and clutch type manual operating mechanism 800;

[0075] The first cylinder 200 is connected to the second cylinder 300 through the box 100; the inside of the first cylinder 200 and the second cylinder 300 are respectively provided with a first piston body 210 and a second piston body 310;

[0076] Piston rod 400, the two ends of the piston rod 400 penetrate into the inside of the first cylinder 200 and the second cylinder 300 respectively, the two ends of the piston rod 400 are respectively connected with the first piston body 210 and the second piston body 310, the piston rod 400 A slider pin connecting hole 410 is provided on the top, and the central axis of the slider pin ...

Embodiment 2

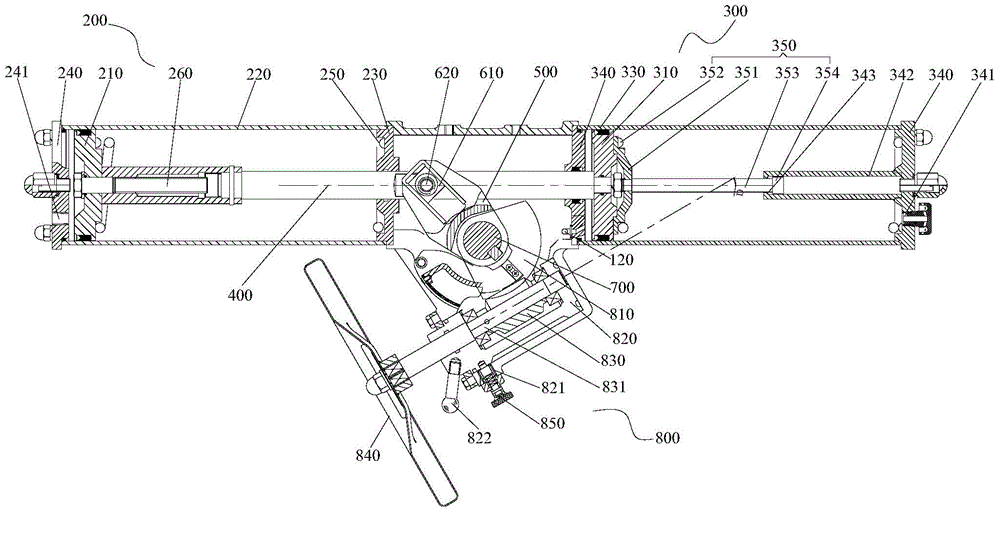

[0092] Such as image 3 and Figure 4As shown, the difference between this embodiment and the embodiment is that when the horizontal-mounted pneumatic piston actuator of the quarter-stroke regulating valve adopts a single-acting structure, the first cylinder 200 also includes a first Spring member 250, the first spring member 250 is between the first guide cover 230 and the first end cover 240, the first spring member 250 is set on the piston rod 400, the first spring member 250 is connected with the first guide cover 230; The second cylinder 300 further includes a second spring component 350 disposed inside the second cylinder body 320 , and the second spring component 350 is located between the second piston body 310 and the second end cover 340 .

[0093] When the pneumatic piston actuator of the angular stroke control valve adopts a single-acting structure, when the piston rod 400 needs to move to the right, the air pressure is input into the first operating air source in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com