Air compressor air storage tank capable of discharging water automatically

A technology of automatic drainage and air compressor, applied in the direction of machines/engines, container discharge methods, mechanical equipment, etc., can solve problems such as equipment loss, achieve the effect of improving quality, improving quality, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

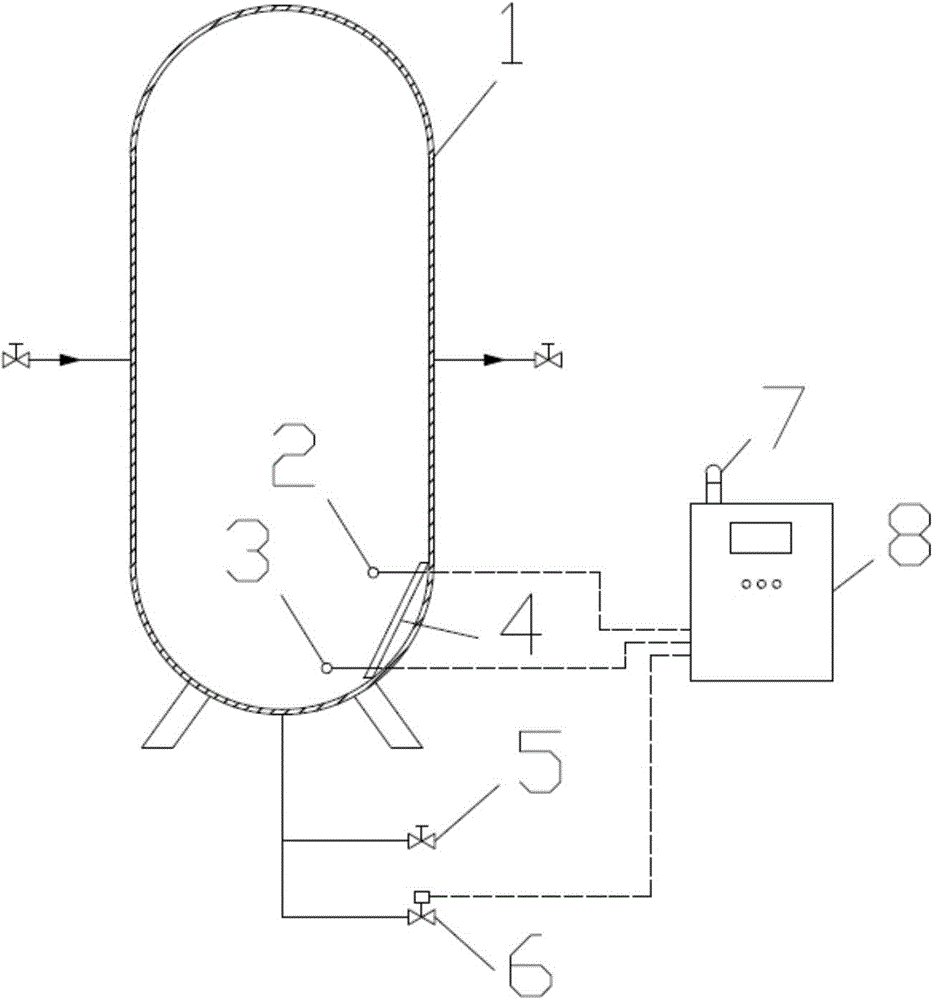

[0021] Such as figure 1 As shown, an air compressor air storage tank with automatic drainage includes a tank body 1 and a manual drain valve 5 arranged on the first drain pipe at the bottom of the tank body 1. The air compressor air storage tank also includes an automatic drainage device, so The automatic drainage device described above includes a fixed adjustment bracket 4 installed at the bottom of the tank body, a high liquid level sensor 2 and a low liquid level sensor 3 respectively arranged at both ends of the fixed adjustment bracket 4, and an electromagnetic sensor arranged at the second drain pipe at the bottom of the tank body. Valve 6, alarm 7 and control box 8.

[0022] The condensed water entering the gas storage tank continuously accumulates at the bottom of the tank body 1. When the liquid level of the condensed water rises to the position that triggers the high liquid level sensor 2, the solenoid valve 6 opens, and the condensed water in the tank body The air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com