A method for blending and transporting Marui crude oil in a long-distance pipeline at room temperature

A long-distance, Maritime-transporting technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of increasing crude oil processing costs, reduce transportation costs and processing costs, and be simple and easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described with the following examples, which are only used to help those skilled in the art understand the present invention, rather than to limit the scope of application of the present invention.

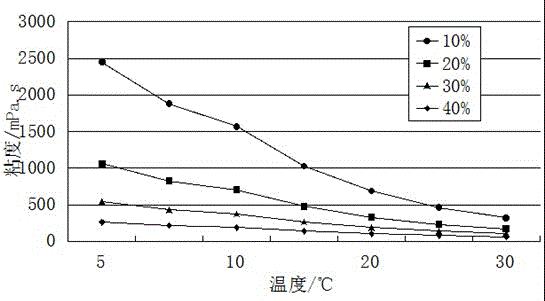

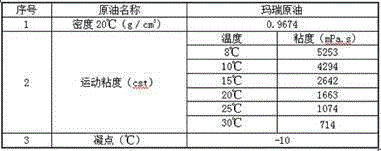

[0018] For domestic waxy crude oil, its shear history and thermal history will affect its viscosity. In the process of the invention, firstly, the relationship between the Marui crude oil and the mixed oil (Marui crude oil + blended crude oil) and the shear rate is measured and analyzed. The results are shown in Table 2:

[0019] Table 2 The relationship between the viscosity and shear rate of the blended oil of Marui crude oil and its blending ratio

[0020]

[0021] It can be seen from the above data that no matter it is Marui crude oil or mixed oil, its viscosity has nothing to do with the shear rate it receives. In addition, the analysis of the viscosity measurement results of Maray crude oil and mixed oils that have undergone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com