A heating furnace safety antifreeze blockage process method and device

A process method and technology of a process device, which are applied in the directions of fluid heaters, lighting and heating equipment, etc., can solve the problems of difficult to maintain and activate standby furnaces, difficulties in normal dehydration of crude oil, and influence on diplomatic work of crude oil, etc., and achieve normal operation. , Solve the problem of freezing blockage and ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

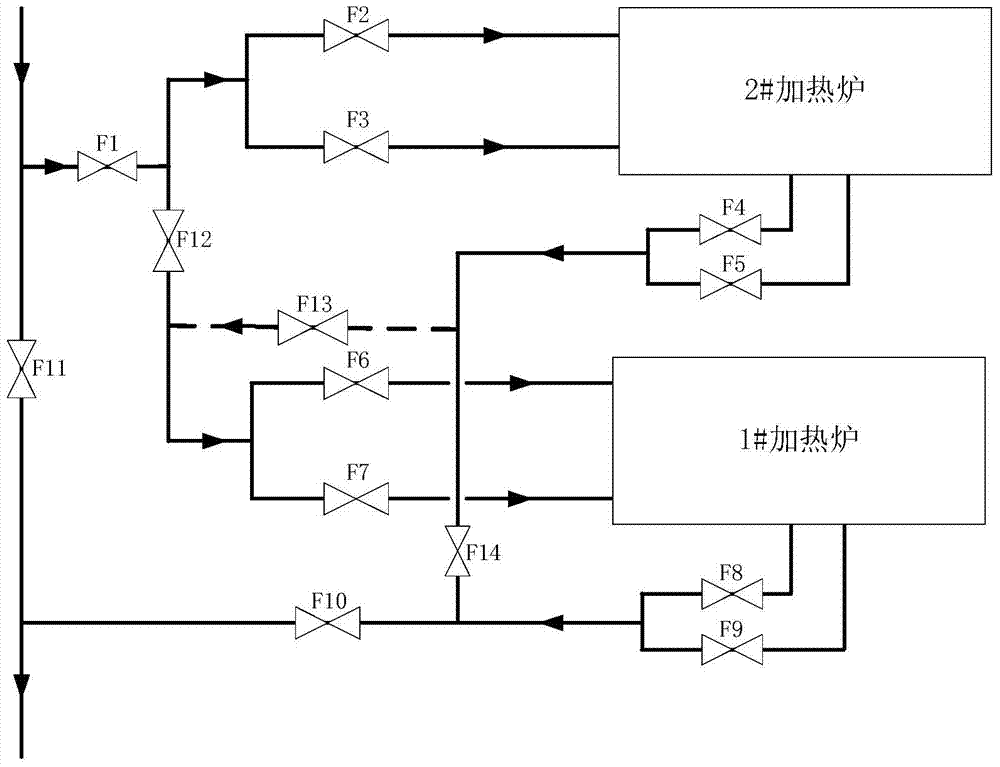

[0015] Embodiment 1: as figure 1 As shown, a heating furnace safety anti-freezing process device, the inlet pipeline is connected to the first inlet valve F1 and the eleventh control valve F11, and the other end of the first inlet valve F1 is connected to the second inlet valve F2, the third inlet valve F3 and the The other ends of the twelfth control valve F12, the second inlet valve F2, and the third inlet valve F3 are connected to the 2# heating furnace, and the outlet pipes of the 2# heating furnace are respectively connected to the fourth outlet valve F4, the fifth outlet valve F5, and the fourth outlet valve. The other ends of the outlet valve F4 and the fifth outlet valve F5 are connected to the thirteenth control valve F13 and the fourteenth outlet control valve F14, the other end of the twelfth control valve F12 is connected to the other end of the thirteenth control valve F13, the tenth The other end of the second control valve F12 and the other end of the thirteenth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com