Overhang Sensor Bracket

A sensor bracket and sensor technology, applied in the direction of instruments, measuring instrument components, measuring devices, etc., can solve the problems of increasing the influence of the fit clearance, enlarging the fit clearance of pin shafts, and increasing the fit clearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

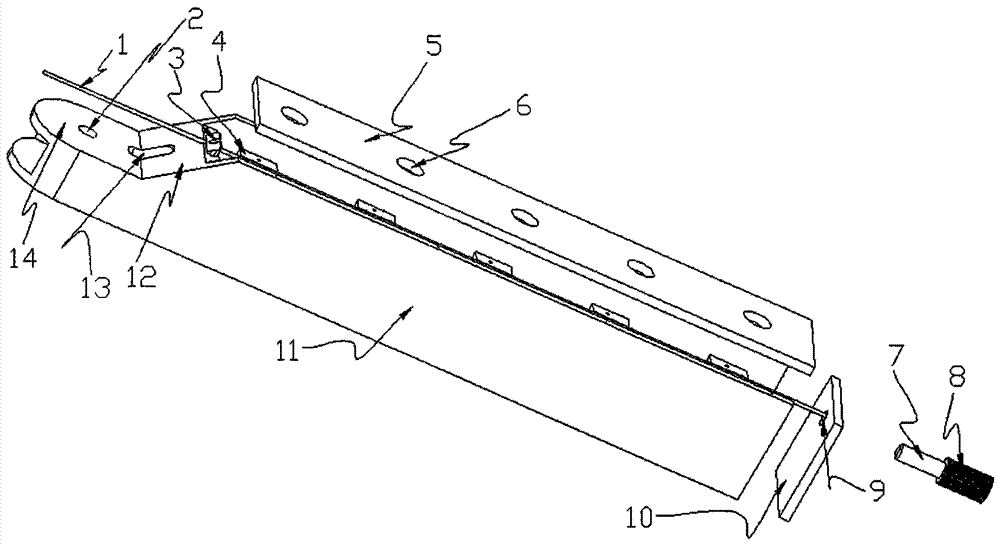

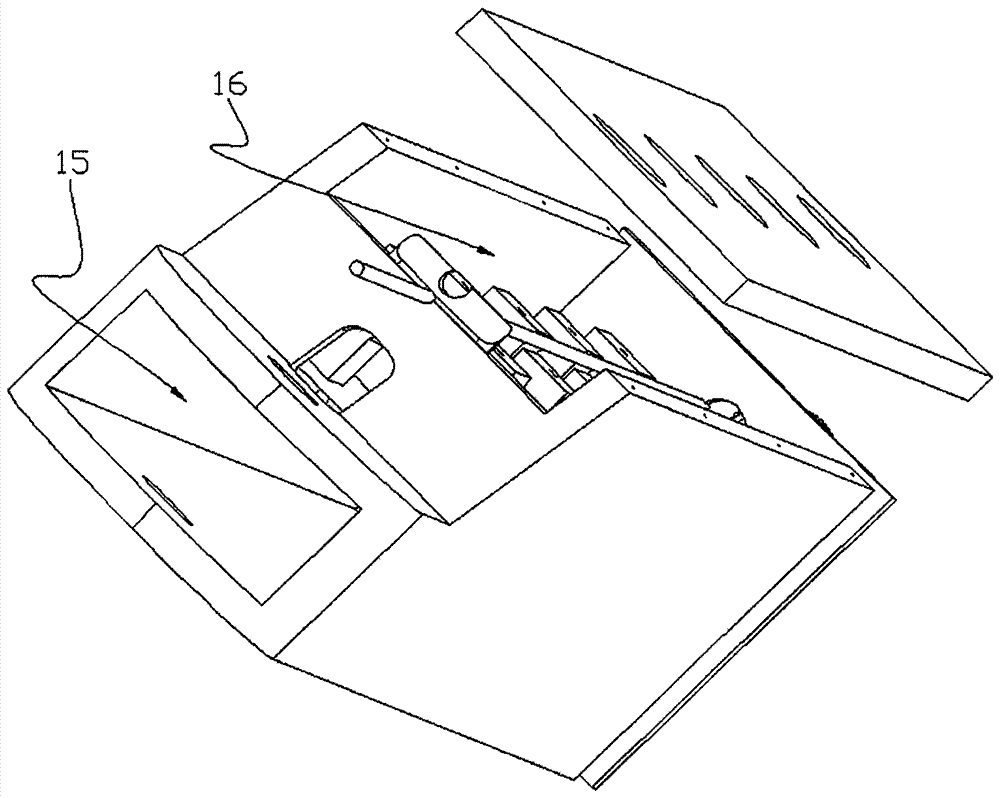

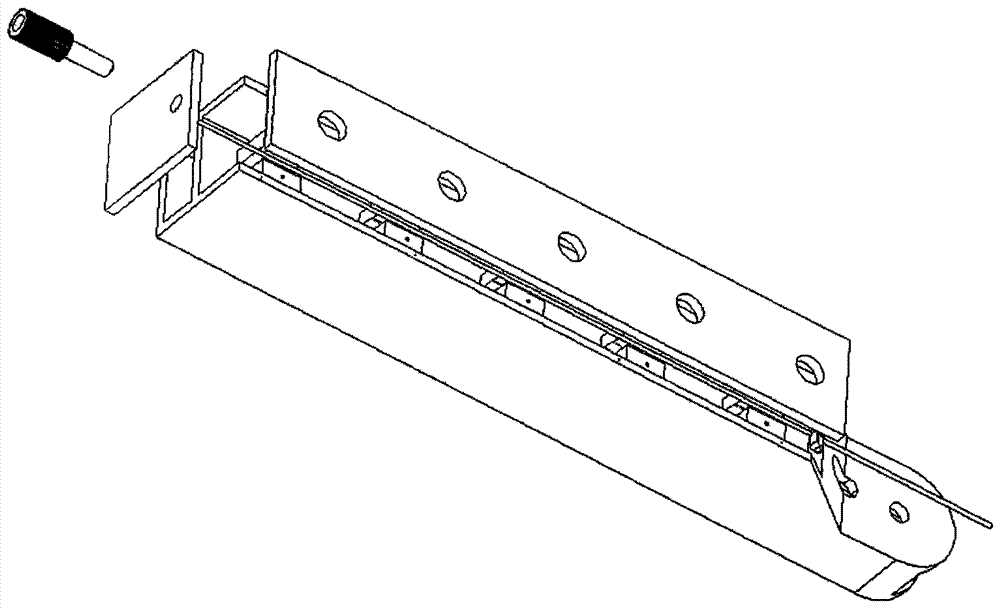

[0039] The cantilever sensor bracket is generally collapsible for easy transportation or storage. This overhanging sensor bracket usually has two states, one is a folded state, and the other is an overhanging state. The overhanging direction mentioned in the present invention refers to the overhanging direction under the overhanging state. technicians can understand.

[0040] As mentioned in the background section, one end of the overhang part is usually installed on the machine body through a pin shaft to form a swing rod, and then a controllable unfolded state, or overhang state, is formed through certain constraints.

[0041] Stress Analysis: For the overhang part, when for example the suspension point of the steel cable 1 is higher than the middle position of the overhang part in the vertical direction, and the other end of the steel cable 1 is also higher than the middle position, the steel cable 1 is pulled, Then the overhanging end of the overhanging part will be subje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com