Workpiece optical testing mechanism

A technology for optical testing and workpieces, applied in the direction of testing optical performance, etc., can solve the problems of wasting time, unfavorable positioning of workpieces, affecting testing results, etc., and achieve the effects of improving testing efficiency, shortening interval testing time, and improving testing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

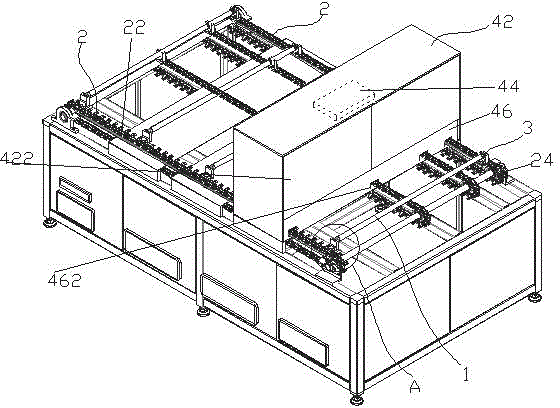

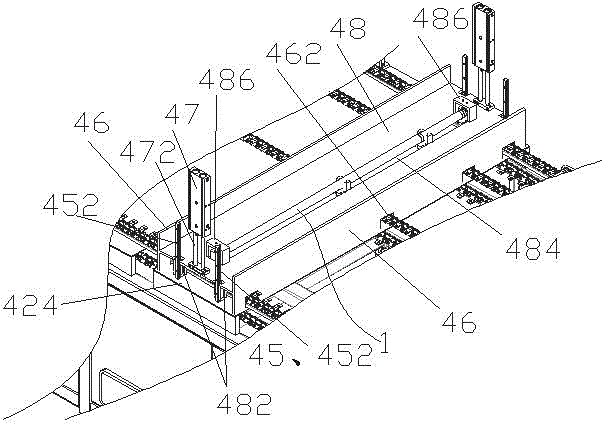

[0025] Such as Figure 1-4 As shown, a workpiece optical testing mechanism specifically includes a hollow dark box 42, an optical testing device is arranged in the dark box 42, and at least two transmission devices 2 are provided. An opening for workpieces to pass is provided on one side upstream in the conveying direction, and a movable door 46 capable of opening and closing the opening is provided.

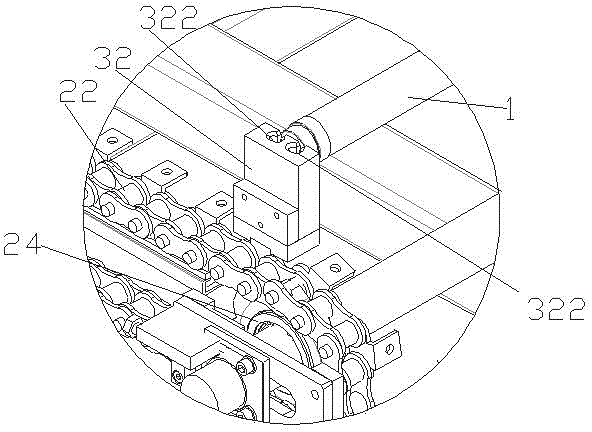

[0026] The conveying device 2 is arranged horizontally through the dark box 42, and is specifically assembled by a chain 22, a sprocket 24 and a driving device according to a conventional method in the art, and each conveying device 2 advances synchronously under the drive of the driving device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com