Clamp for fixing slide

A technology for fixing glass slides and fixtures, applied in the field of slide staining, which can solve the problems of poor staining effect, time-consuming, and large waste of staining solution, and achieve the effect of improving staining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

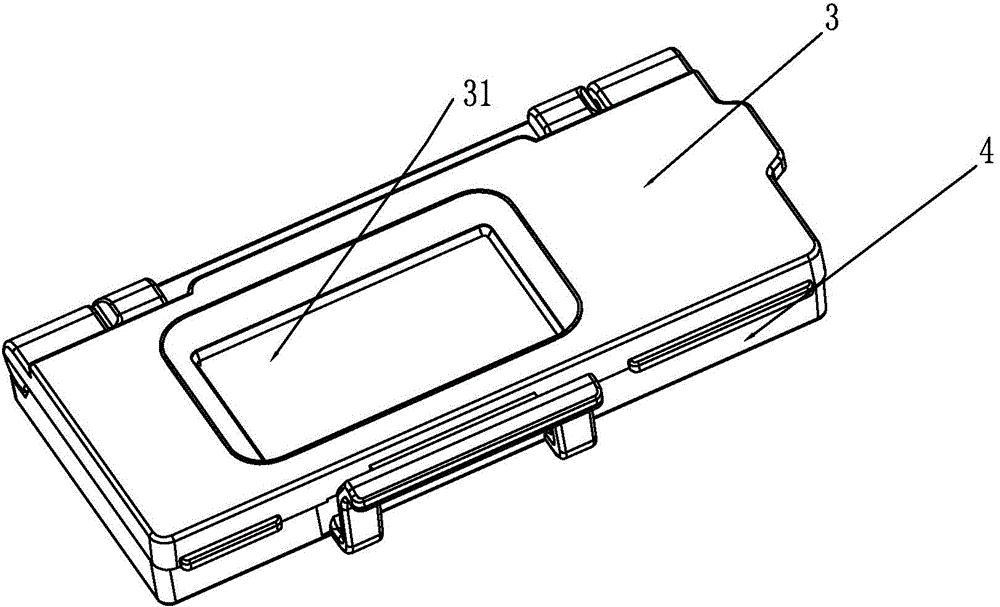

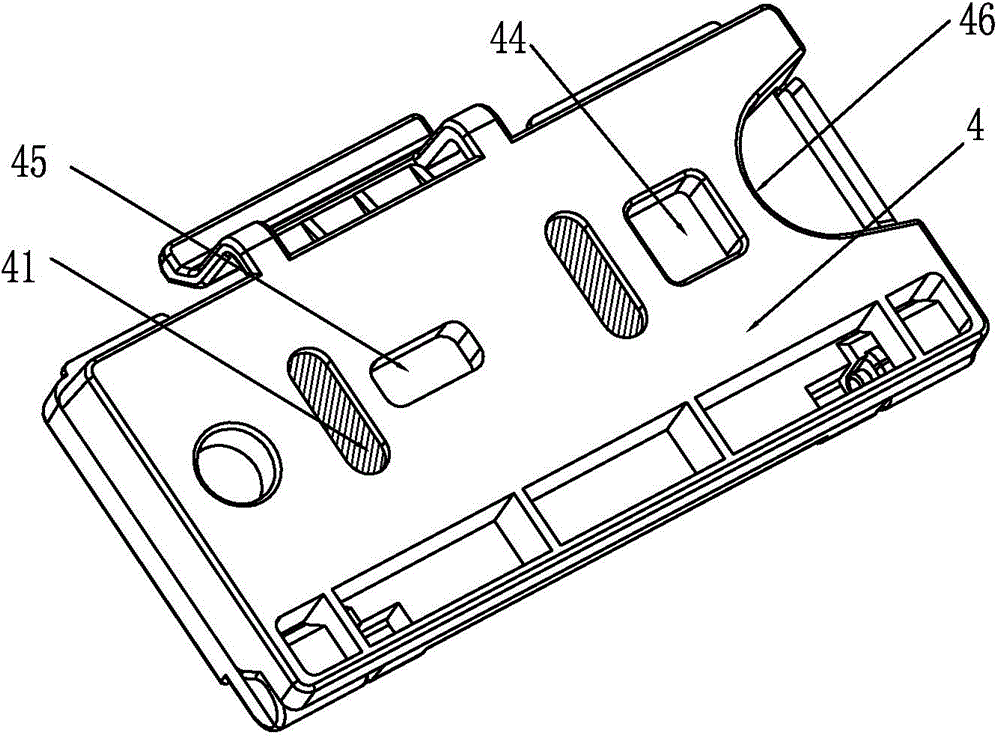

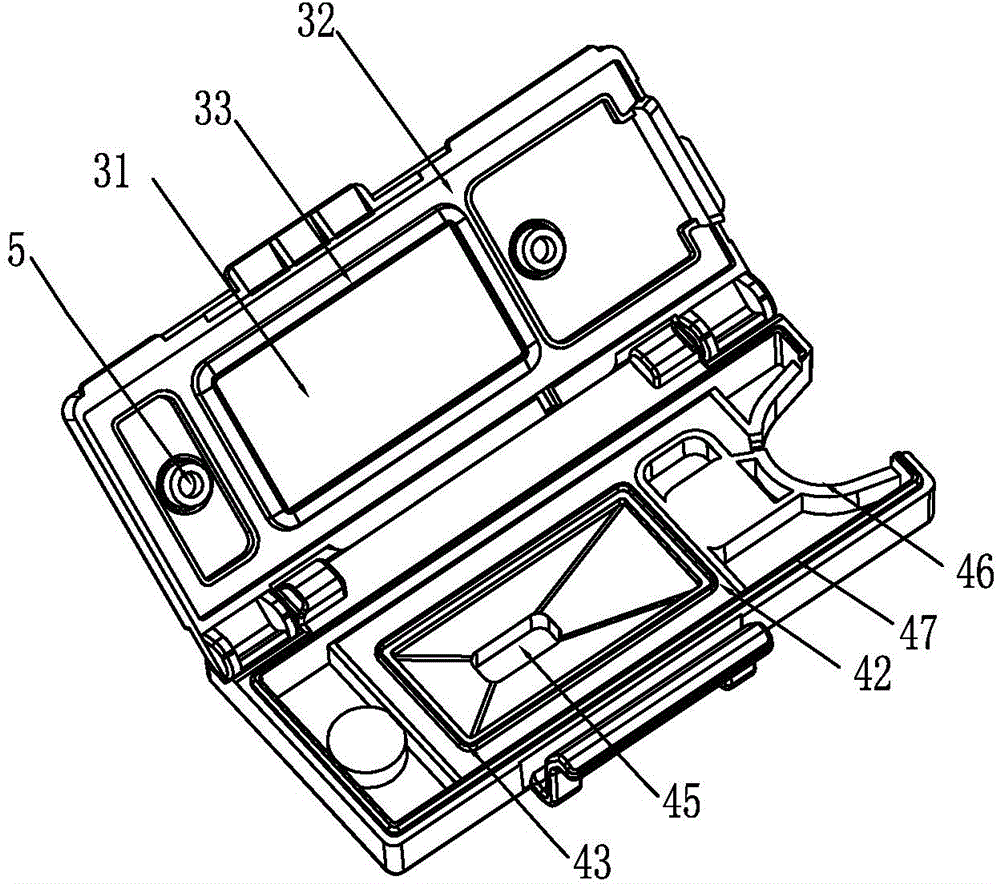

[0023] see figure 1 , a fixture for fixing glass slides of the present invention includes an upper cover 3 and a lower cover 4, wherein the upper cover 3 has a staining window 31, and the inclined surface of the staining window 31 expands outward. The upper cover 3 and the lower cover 4 are connected by hinges, and are fastened together by snap fit, and the slide 2 is fixedly clamped between the upper cover 3 and the lower cover 4 .

[0024] see further image 3 and Figure 4 , the upper cover 3 and the inner surface of the lower cover 4 are respectively coated with an upper elastic body 32 and a lower elastic body 42, such as elastic materials such as TPU, and the upper elastic body 32 is provided with an upper protruding position 33 at the edge of the dyeing window 31, and the lower elastic body The body 42 is provided with a lower protruding position 43 corresponding to the upper protruding position 33, and the upper protruding position 33 and the lower protruding positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com