Calibration device for rolling wear testing machine

A rolling wear and calibration device technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of large human factors and poor measurement accuracy, and achieve the effects of convenient use, good effect and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

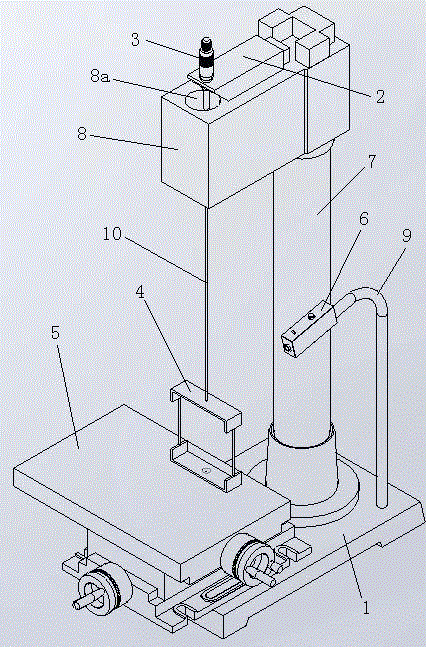

[0021] Depend on figure 1 Given, the present invention comprises support, force transducer and two-dimensional platform, and support comprises base 1, the column 7 that is vertically contained on base 1 and the upper fixed base 8 that is contained in the column top, and force sensor 2 is housed on upper fixed base 8, and force The force sensitive element of the sensor 2 is equipped with a screw adjusting knob 3, and the lower end of the screw adjusting knob 3 is suspended with a hanger 4 through a pull rope 10, and the pressure received by the hanger can be transmitted to the force sensor through the pull rope and the screw adjust knob, forming a suspension type. A force-measuring structure, a horizontal two-dimensional platform 5 is installed on the base 1 under the suspension 4, and a rotational speed sensor 6 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com