Optimal noise coefficient testing method

A technology of noise figure and test method, applied in the direction of noise figure or signal-to-noise ratio measurement, to achieve the effect of overcoming expensive equipment, reducing test cost, and overcoming few test resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

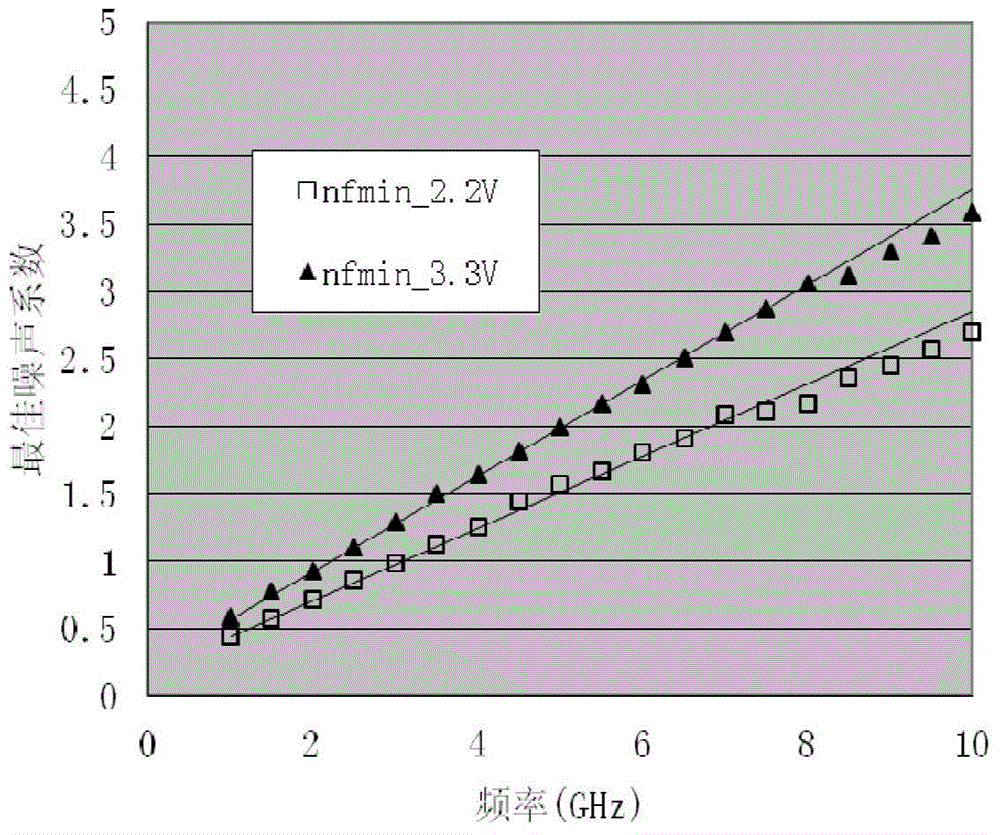

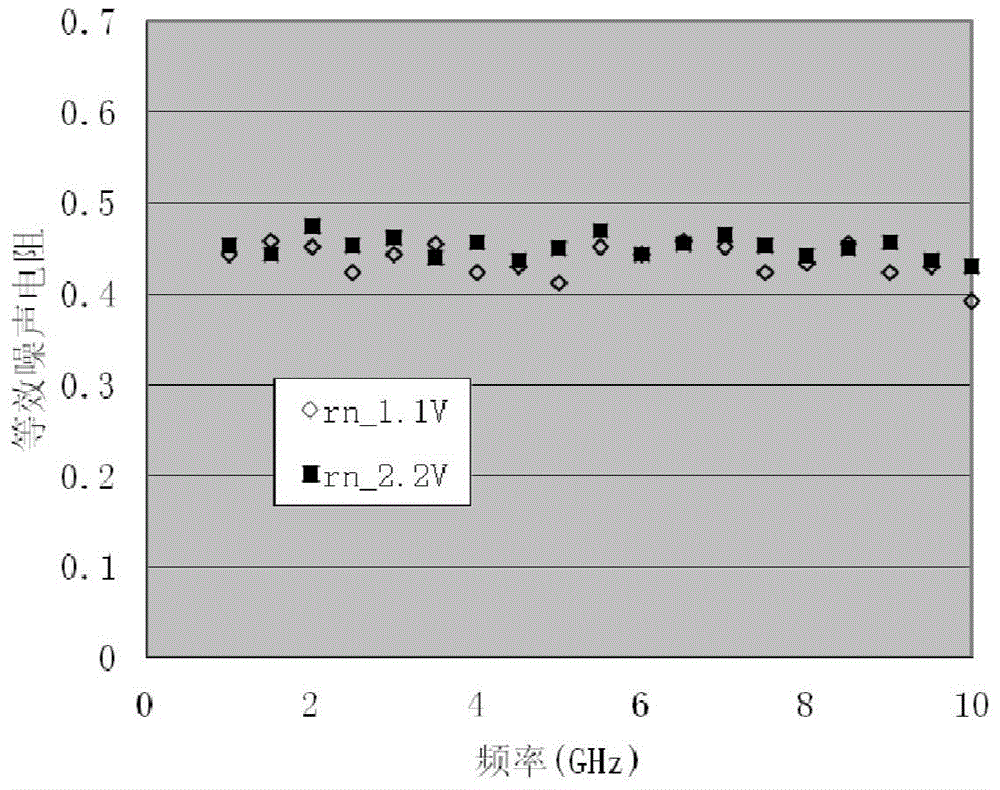

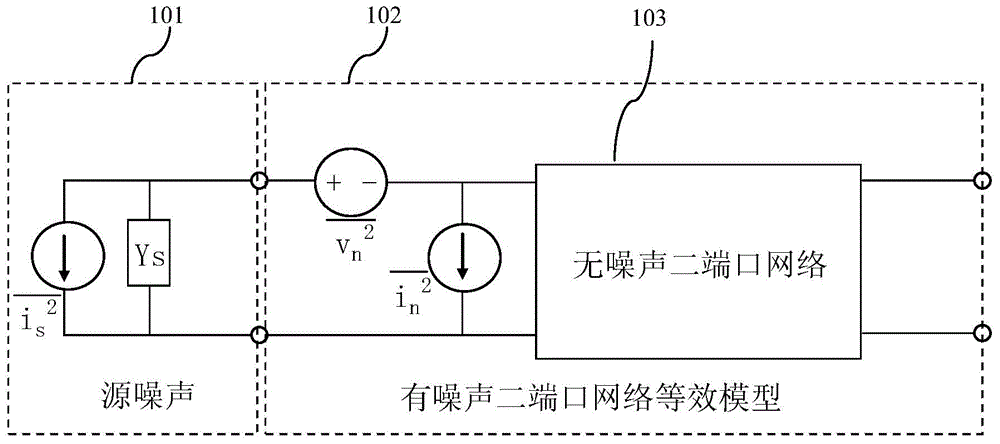

[0042] High frequency noise theoretical formula: F = F min + R n G s [ ( G s - G opt ) 2 + ( B s - B opt ) 2 ] , F stands for noise figure, F min Indicates the best noise figure, R n Indicates the equivalent noise resistance, G s is the source conductance, B s is the source susceptance, G opt Indicates the best source conductance, B opt Indicates the optimum source susceptance.

[0043] Among them, the optimal noise fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com