Automatic testing system for power supply

A technology of automated testing and power supply, applied in the direction of power supply testing, etc., can solve problems such as electrical accidents, power supply function and performance test analysis, complex operation, etc., and achieve the effect of avoiding the influence of human factors, objective test results, and accurate test basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

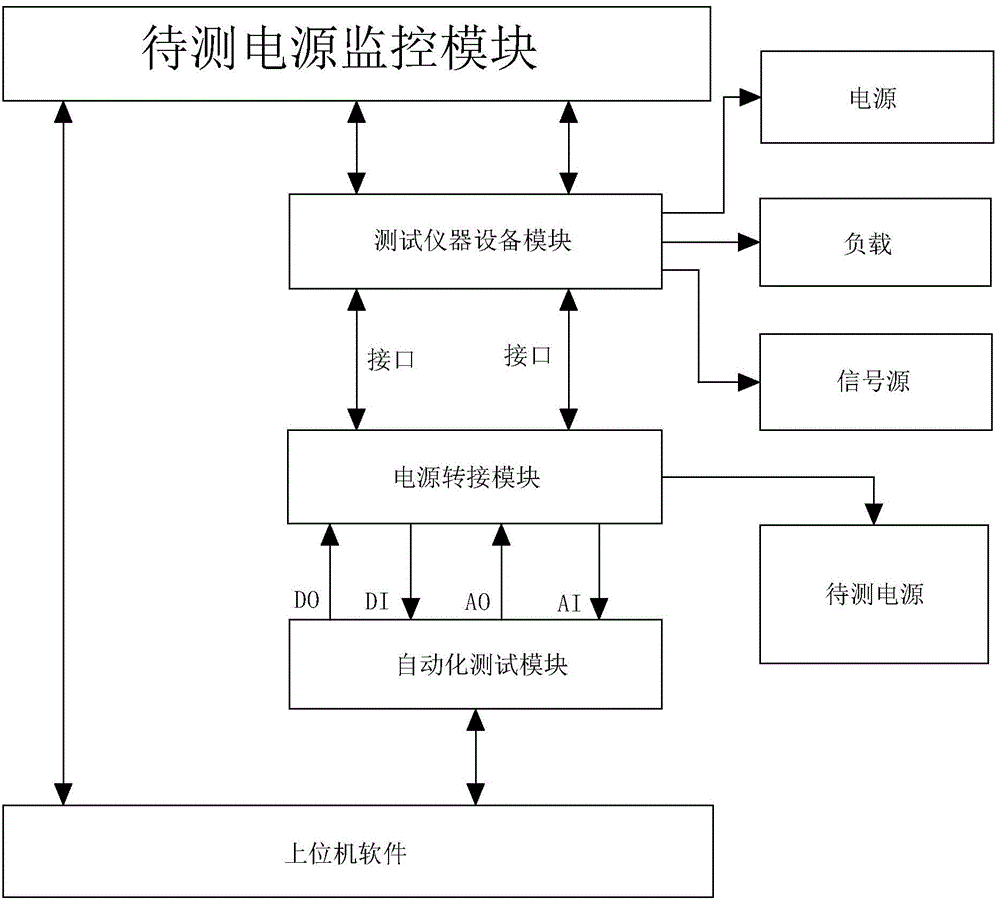

[0018] refer to figure 1 As shown, an automatic test system for a power supply of the present invention includes a power supply to be tested, the power supply to be tested is connected to a power adapter module, the power adapter module is connected to a test instrument equipment module and an automated test module, and the test instrument The equipment module is connected to the power supply monitoring module to be tested and the test equipment, the automated test module is connected to the host computer software, and the host computer software is connected to the power supply monitoring module to be tested by communication; wherein:

[0019] The host computer software generates the corresponding automated test module by compiling the test script to identify the received test data, and the automated test module converts the test data into corresponding interface data after receiving the test data sent by the host computer software, and passes Send interface data to control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com