Silver-doped defect negative refraction photonic crystal three-flat plate group detection system

A photonic crystal and detection system technology, applied in the optical field, can solve the problems of small longitudinal detection distance and small refocusing resolution, and achieve the effects of amplifying strong stimulated radiation, improving refocusing resolution, and increasing transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

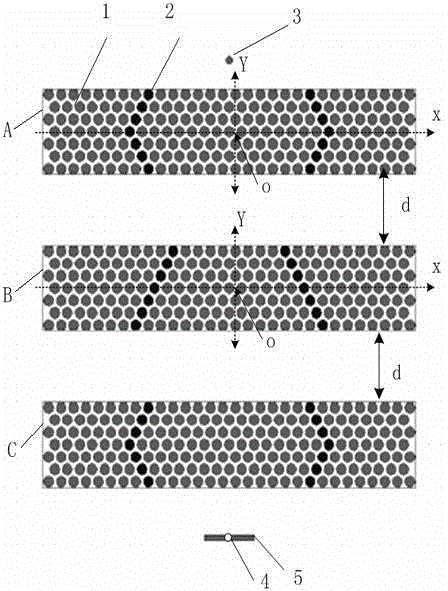

[0014] see figure 1 , the entire detection system of the present invention is composed of a light source 4, a detector 5 and three parallel NR-PC (equivalent negative refraction photonic crystal) flat lenses doped with silver defect impurities on the upper, middle and lower sides. The three flat lenses form a photon Crystal triple plate lens group. The three flat lenses are separated by air, and the air separation distance between two adjacent flat lenses is the same, both being d. Among them, the arrangement structure of silver defects in the upper and lower plate lenses A and C is the same, and the structure of the middle plate lens B between the upper and lower plate lenses A and C is slightly different. by figure 1 The structure is a periodic unit, and the photonic crystal three-plate lens group is arbitrarily extended to the left and right in the x direction (length direction) to form a detection and imaging system. The target diameter of detection target 3 is D =1 / 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com