Optical component support structure, unit lens group, exposure optical system and photoetching machine

A technology for exposing optical systems and optical components, which is applied in the field of high-precision optical lens manufacturing and assembly, which can solve problems such as complex structure, difficult assembly, and occupancy, and achieve the effects of active compensation, easy processing and manufacturing, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

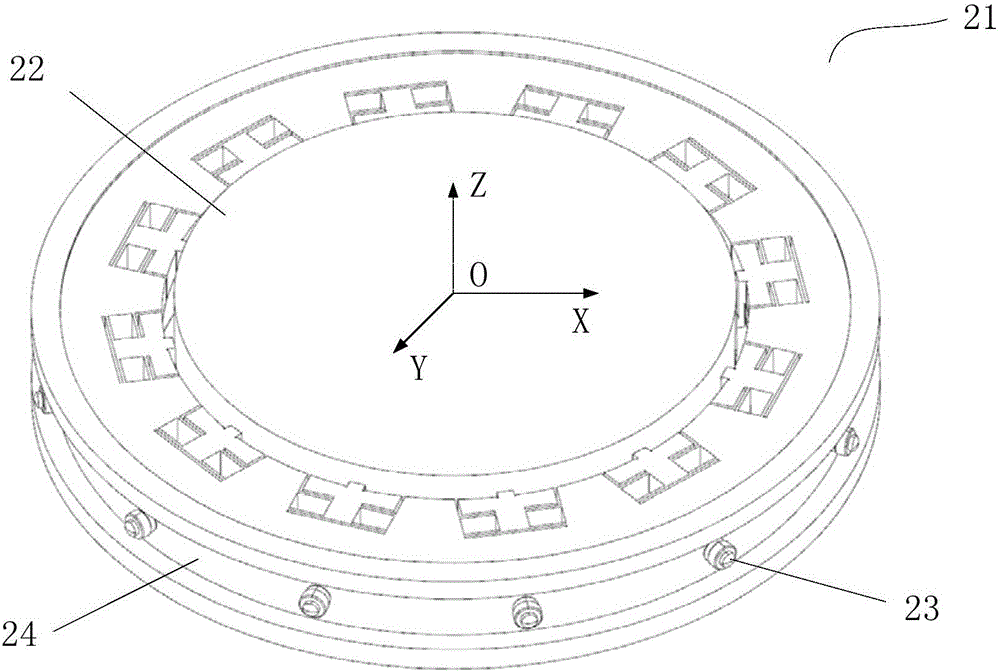

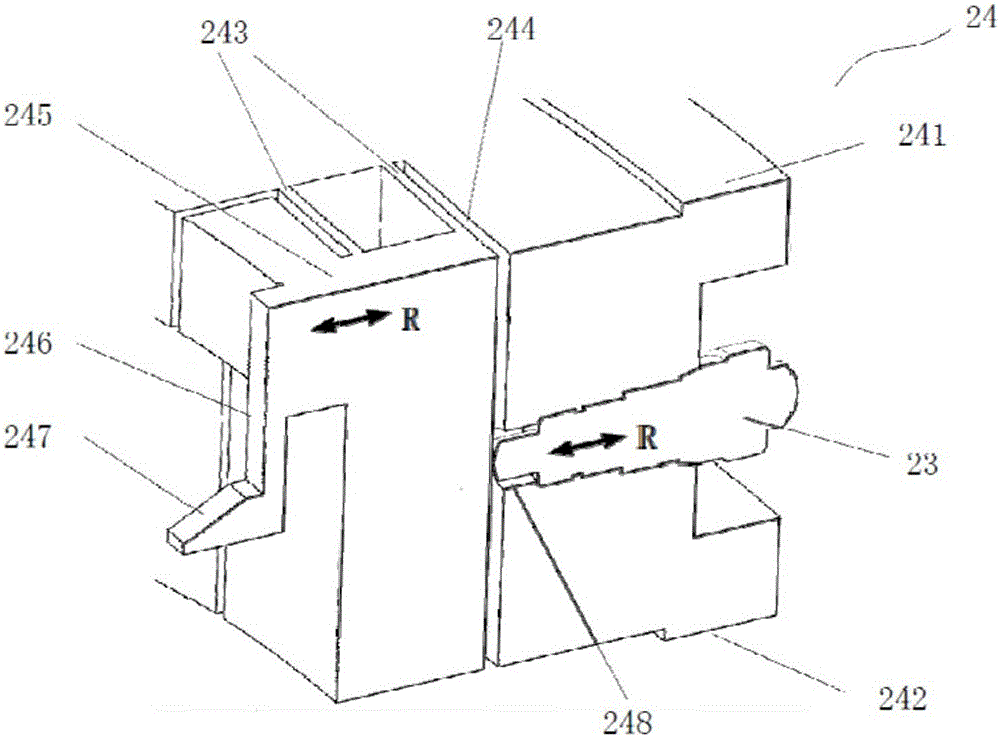

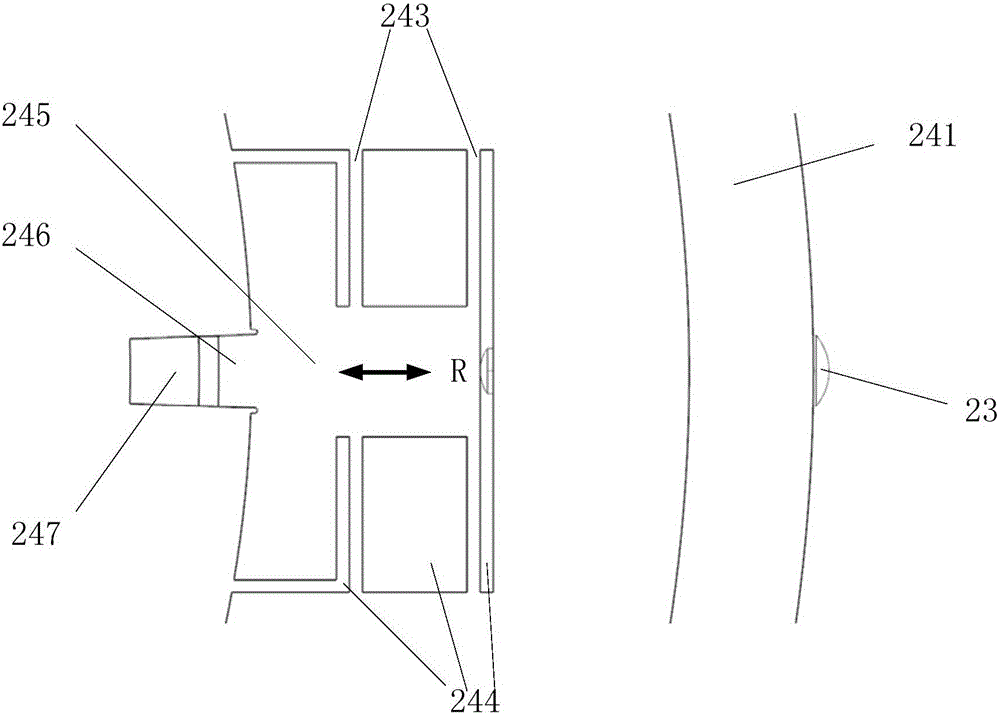

[0028] combine Figure 1 to Figure 5 , the optical element supporting structure provided by an embodiment of the present invention includes a mirror base 24 and a driving mechanism 23 . The mirror base 24 includes an upper connecting flange 241 , a lower connecting flange 242 , a guiding mechanism 243 , a slit 244 , a moving platform 245 , a supporting rod 246 , a supporting surface 247 and a positioning hole 248 which are integrally formed.

[0029] Such as figure 1, the supporting structure of the optical element is included in the unit lens group 21 , and the unit lens group 21 is usually composed of an optical element 22 , a driving mechanism 23 and a lens holder 24 . Usually, the direction parallel to the optical axis of the optical element 22 is defined as the Z axis, the center of the coordinate system is located at the center of the upper or lower surface of the optical element 22, and the plane perpendicular to the Z axis is the XY plane. The material of the optical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com