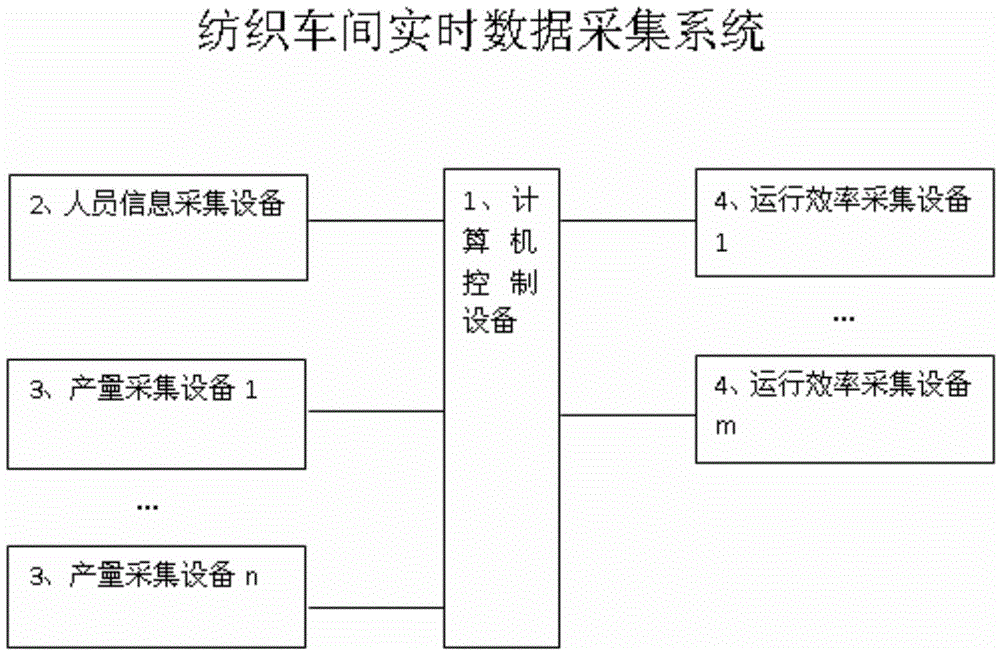

Real-time data acquisition system for textile workshop

A technology of real-time data acquisition and data acquisition system, which is applied in the general control system, control/regulation system, comprehensive factory control, etc., and can solve the problem of not being able to meet the textile workshop management without the combination of equipment data acquisition and personnel information data acquisition. Issues such as lack of data collection requirements and poor real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

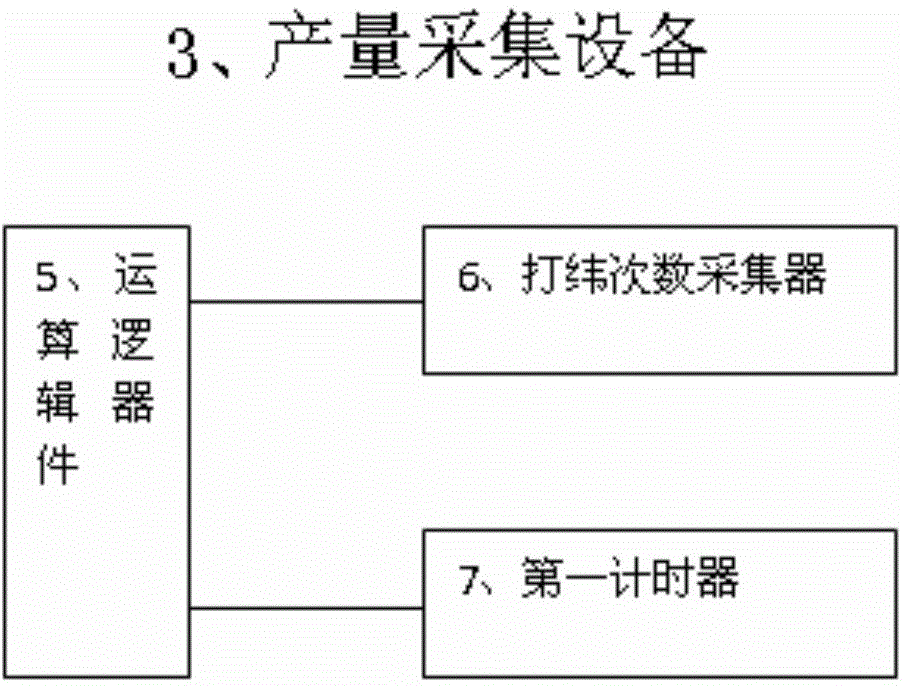

[0016] The embodiment of the real-time data acquisition system of the textile workshop of the present invention will be described in detail below with reference to the accompanying drawings.

[0017] Textile machinery, also known as textile machinery, is a variety of mechanical equipment required to process natural fibers or chemical fibers into textiles. Textile machinery in a broad sense also includes chemical machinery for the production of chemical fibers. Textile machinery is the production means and material basis of the textile industry. Its technical level, quality and manufacturing cost are directly related to the development of the textile industry.

[0018] Although the machinery for producing chemical fibers includes a variety of chemical machinery, it is now considered an extension of textile machinery and belongs to textile machinery in a broad sense. The processes required to process different fibers such as cotton, hemp, silk, wool, etc. into textiles are not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com