Automatic liquid level controller for industrial wastewater treatment

An automatic controller and industrial sewage technology, applied in the direction of liquid level control, non-electric variable control, control/regulation system, etc., can solve the problems of inaccurate control and complex structure, and achieve the effect of precise control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

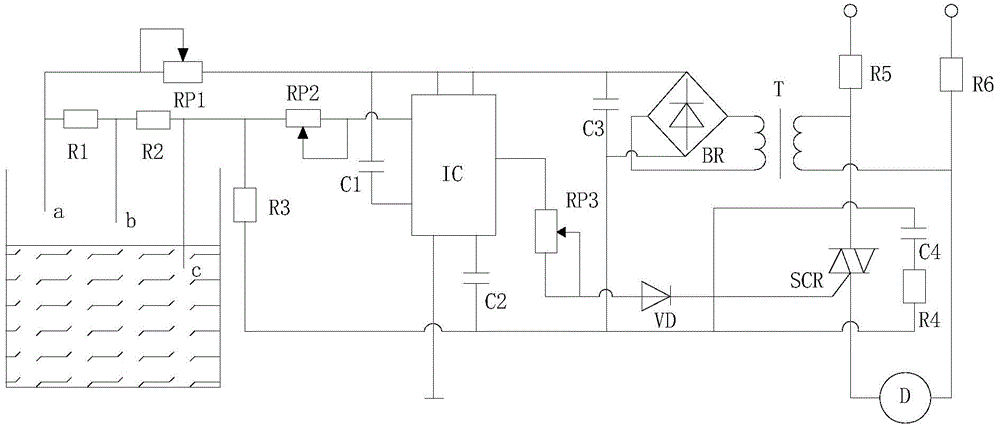

[0009] The present invention will be further described below in conjunction with accompanying drawing:

[0010] Such as figure 1 As shown, the present invention is an automatic liquid level controller for industrial sewage treatment, including time base chip IC, water pump D, bidirectional thyristor SCR, bridge finishing circuit BR, diode VD, first potentiometer RP1, second Two potentiometer RP2, third potentiometer RP3, first resistor R1, second resistor R2, third resistor R3, fourth resistor R4, fifth resistor R5, sixth resistor R6, first capacitor C1, second capacitor C2 , the third capacitor C3 and the fourth capacitor C4, the a detection port is respectively connected with the first end of the first resistor R1, the first end of the first potentiometer RP1 and the sliding end of the first potentiometer RP1, and the b detection port is connected with the first end of the first potentiometer RP1 respectively. The second terminal of the first resistor R1 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com