Steel pipe counter

A counting machine and steel pipe technology, applied in the direction of counting mechanism/objects, instruments, etc., can solve the problems that steel pipes cannot accurately and efficiently count the number of steel pipes, reduce the work efficiency of the construction team, and consume the physical strength of workers. The effect of increasing friction coefficient and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

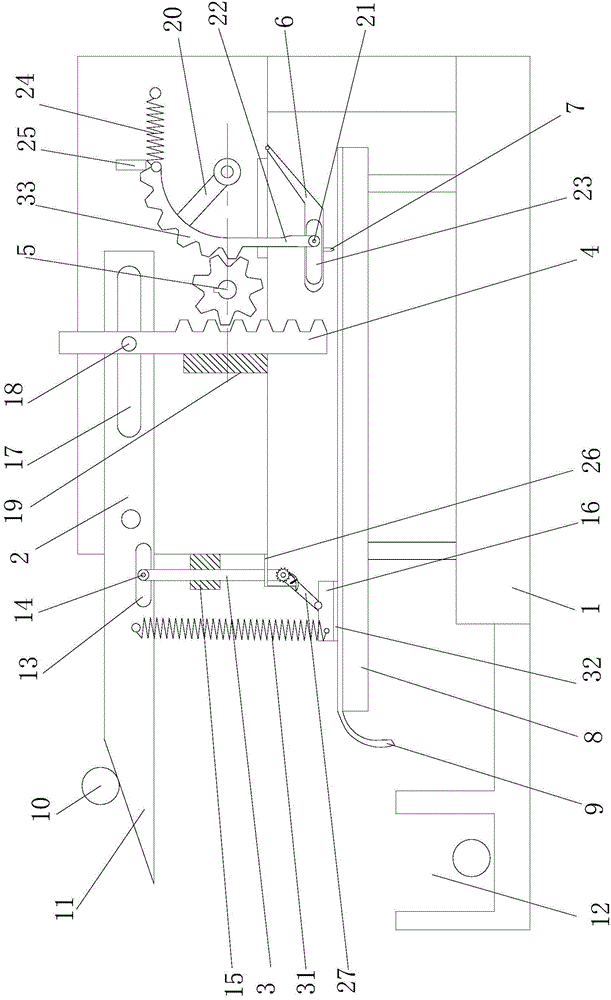

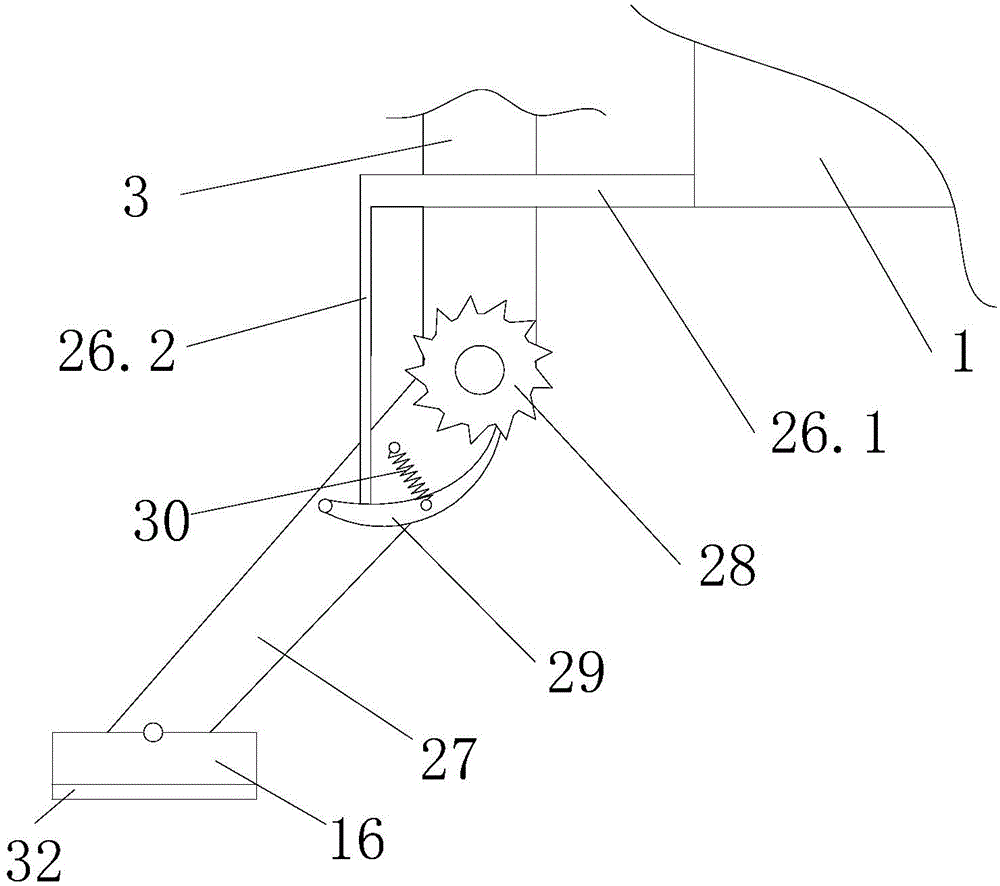

[0017] As shown in the figure, the steel pipe counting machine of the present invention includes a base 1, a connecting rod 2, a push rod 3, a linear rack 4, a gear 5, an arc rack 33, a rocking plate 6 and a punch 7, and on the base 1 A workbench 8 is provided, and a paper tape 9 is laid on the workbench 8; the middle part of the connecting rod 2 is hinged with the base 1, and the left end of the connecting rod 2 is provided with an inclined platform 11 for the steel pipe 10 to roll; The base 1 is provided with a blanking chute 12 for accommodating the steel pipe 10; the left end of the link rod 2 is provided with a first chute 13, and the upper end of the push rod 3 is provided with a first roller 14 for rolling and matching with the first chute 13 , the outer wall of the push rod 3 is covered with a sleeve 15, the sleeve 15 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com