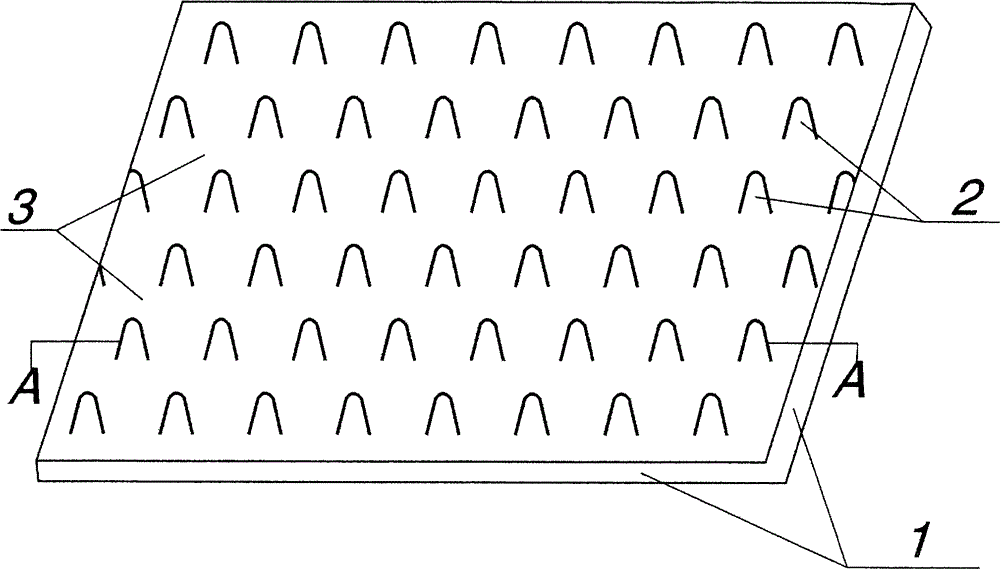

Thin-film solar cell of relief structure

A solar cell and embossing technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of aggravated power attenuation, adverse solar cell surface heat dissipation, etc., to reduce reflection loss, strengthen light capture ability, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

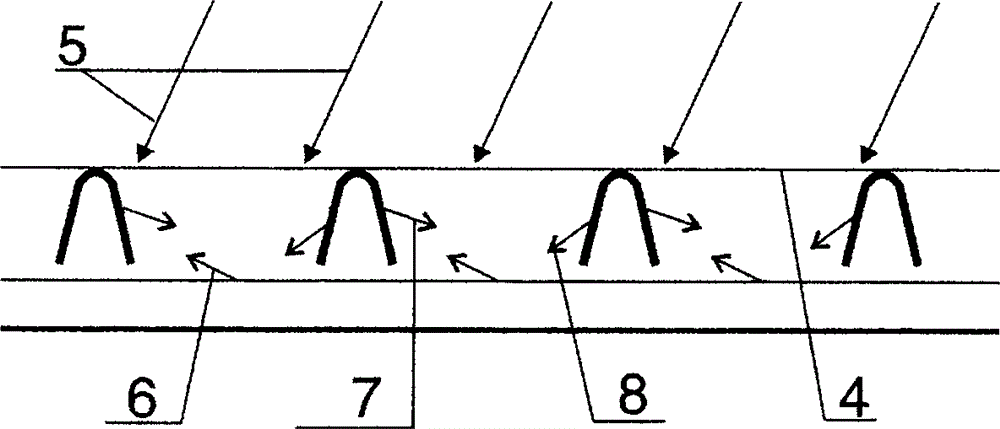

[0017] When the incident sunlight (5) enters the surface of the solar cell with an embossed group structure through the protective film (4), reflected light (6) is generated on the surface flow channel (3), and reflection is generated on the surface of the embossed body (3) Rays (7) and secondary reflected rays (8) form diffuse reflections and repeated reflections for multiple absorptions. Thereby, the reflection loss of light is naturally reduced, the conversion rate is improved, the brightness is reduced, and light pollution is avoided.

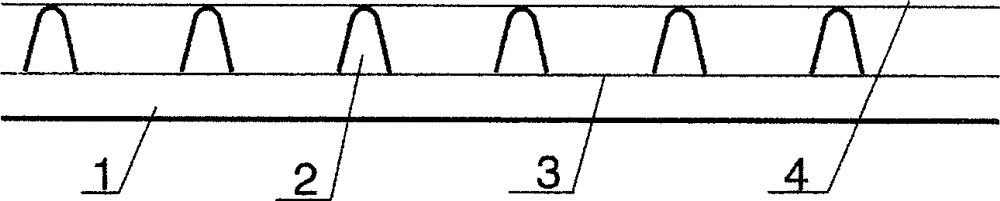

[0018] At the same time, the embossed structure (2) of the present invention effectively strengthens the light-harvesting ability of the solar cell, reduces the complicated process of using laser or chemical methods to make the surface of the existing solar cell film "velvet", and reduces the manufacturing cost .

[0019] Furthermore, the surface flow channel (3) between the embossing bodies (2) also unblocks the discharge of hot air on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com