A kind of preparation method of bismuth-doped polymeric carbon nitride nanocomposite containing carbon defects

A nano-composite material and carbon nitride technology, applied in the analysis of materials, material electrochemical variables, material analysis by electromagnetic means, etc., can solve the problems of narrow light absorption range of a single PCN, imperfect technical solutions, harsh experimental conditions, etc. , to achieve the effect of improving light capture ability, improving photoelectric activity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

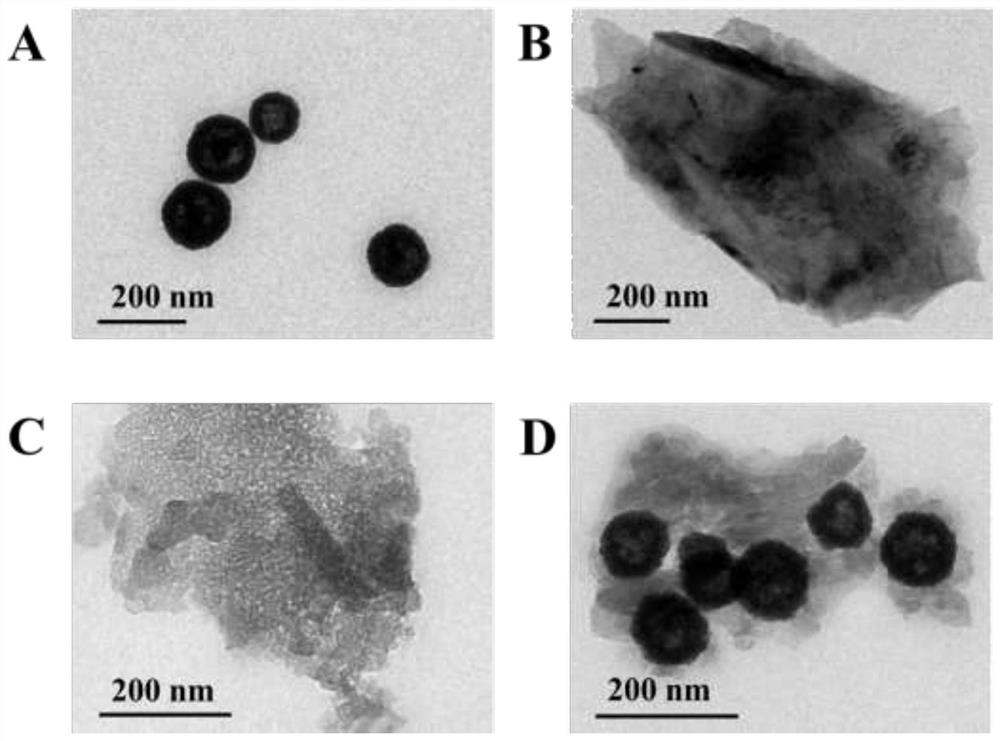

[0041] Preparation of Bismuth-doped Polymerized Carbon Nitride Nanocomposites Containing Carbon Defects

[0042] (1) Preparation of ultrathin PCN nanosheets

[0043] First, 2 g of melamine and 0.2 g of TAP were mixed in 60 mL of ethanol, the mixture was stirred and then heated at 100 °C until the ethanol evaporated to obtain a solid product. Afterwards, use 5 g of molten salt (including NaCl and KCl, wherein the molar ratio of NaCl and KCl is 76:24) as a solvent and template to accelerate the polymerization process, grind with a mortar and mortar to form a homogeneous mixture with the obtained solid product, and put it into the lid In a porcelain crucible, it was heated at 550°C for 4h at a heating rate of 12°C / min, and the final product was marked as PCN.

[0044] For comparison, g-C was synthesized according to the melamine polymerization method reported in the literature 3 N 4 .

[0045] (2) Preparation of bismuth-doped polymeric carbon nitride nanocomposites containing...

Embodiment 2

[0064] Preparation of Bismuth-doped Polymerized Carbon Nitride Nanocomposites Containing Carbon Defects

[0065] (1) Preparation of ultrathin PCN nanosheets

[0066] First, 1 g of melamine and 0.1 g of TAP were mixed in 50 mL of ethanol, the mixture was stirred and then heated at 100 °C until the ethanol evaporated to obtain a solid product. Afterwards, use 4 g of molten salt (including NaCl and KCl, wherein the molar ratio of NaCl and KCl is 76:24) as a solvent and a template to accelerate the polymerization process, grind with a mortar together with the obtained solid product to form a homogeneous mixture, put into the lid In a porcelain crucible, it was heated at 550 °C for 3 h at a heating rate of 12 °C / min, and the final product was marked as PCN.

[0067] (2) Preparation of bismuth-doped polymeric carbon nitride nanocomposites containing carbon defects

[0068] First, 0.145g Bi(NO 3 ) 3 ·5H 2 O dissolved in 9mL with a concentration of 1mol L -1 HNO 3middle. Then,...

Embodiment 3

[0070] Preparation of Bismuth-doped Polymerized Carbon Nitride Nanocomposites Containing Carbon Defects

[0071] (1) Preparation of ultrathin PCN nanosheets

[0072] First, 3 g of melamine and 0.3 g of TAP were mixed in 70 mL of ethanol, the mixture was stirred and then heated at 100 °C until the ethanol evaporated to obtain a solid product. Afterwards, use 6g of molten salt (including NaCl and KCl, wherein the molar ratio of NaCl and KCl is 76:24) as a solvent and template to accelerate the polymerization process, grind with a mortar to form a homogeneous mixture together with the obtained solid product, put into the lid In a porcelain crucible, it was heated at 550°C for 5h at a heating rate of 12°C / min, and the final product was marked as PCN.

[0073] (2) Preparation of bismuth-doped polymeric carbon nitride nanocomposites containing carbon defects

[0074] First, 0.218g Bi(NO 3 ) 3 ·5H 2 O dissolved in 11mL with a concentration of 1mol L -1 HNO 3 middle. Then, 60 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com