Rare earth trimesic acid complex/yttrium oxide/titanium dioxide composite photo-anode and construction method thereof

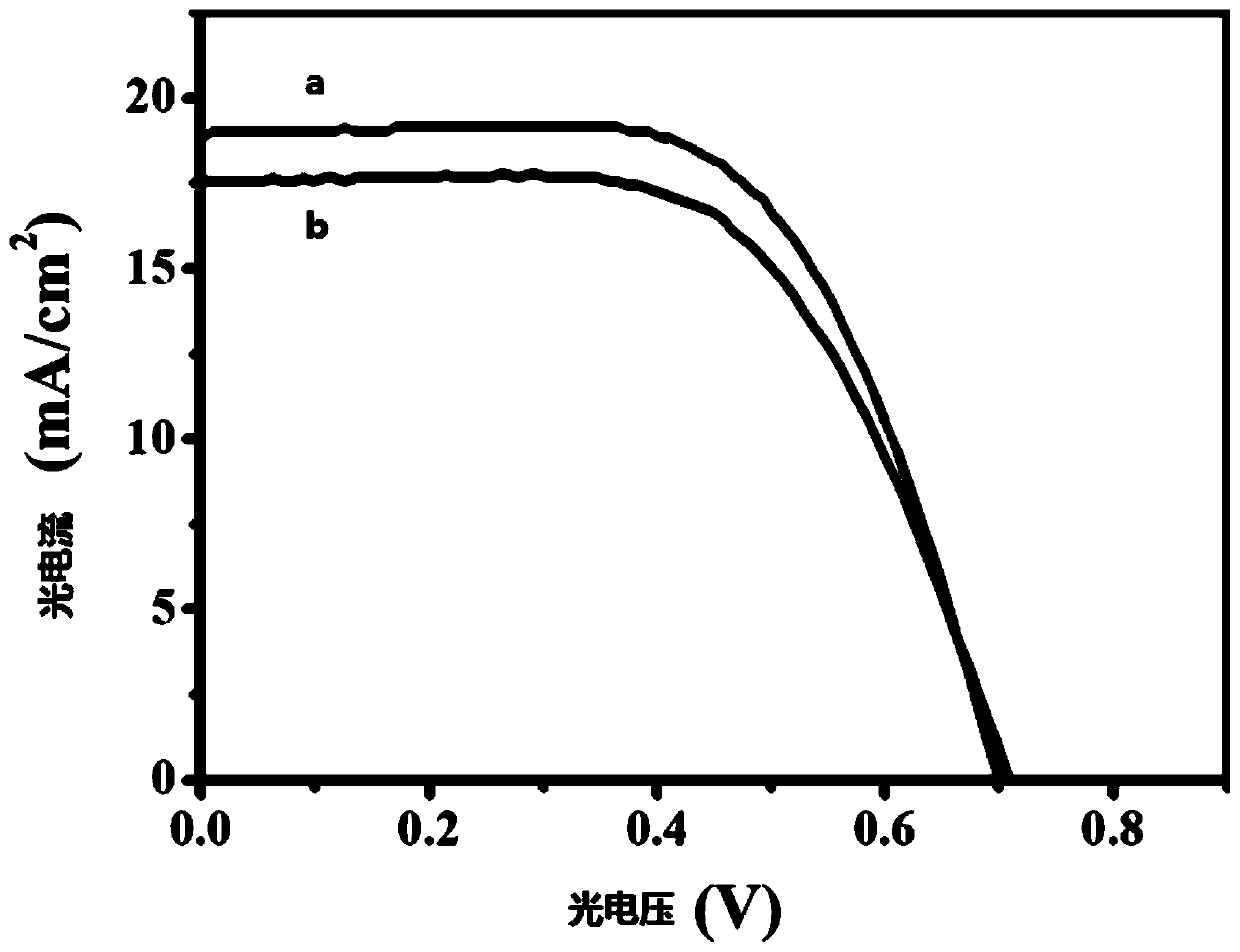

A technology of trimesic acid and yttrium trioxide, applied in photosensitive equipment, photovoltaic power generation, sustainable manufacturing/processing, etc., can solve the problems of low photoelectric conversion efficiency, improve photocurrent and light utilization, and improve photoelectric performance , Improve the effect of light capture ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

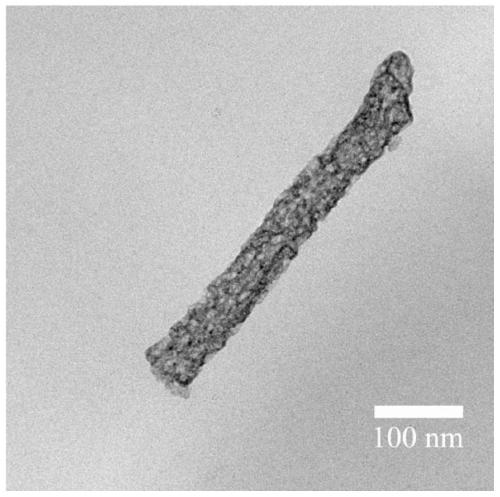

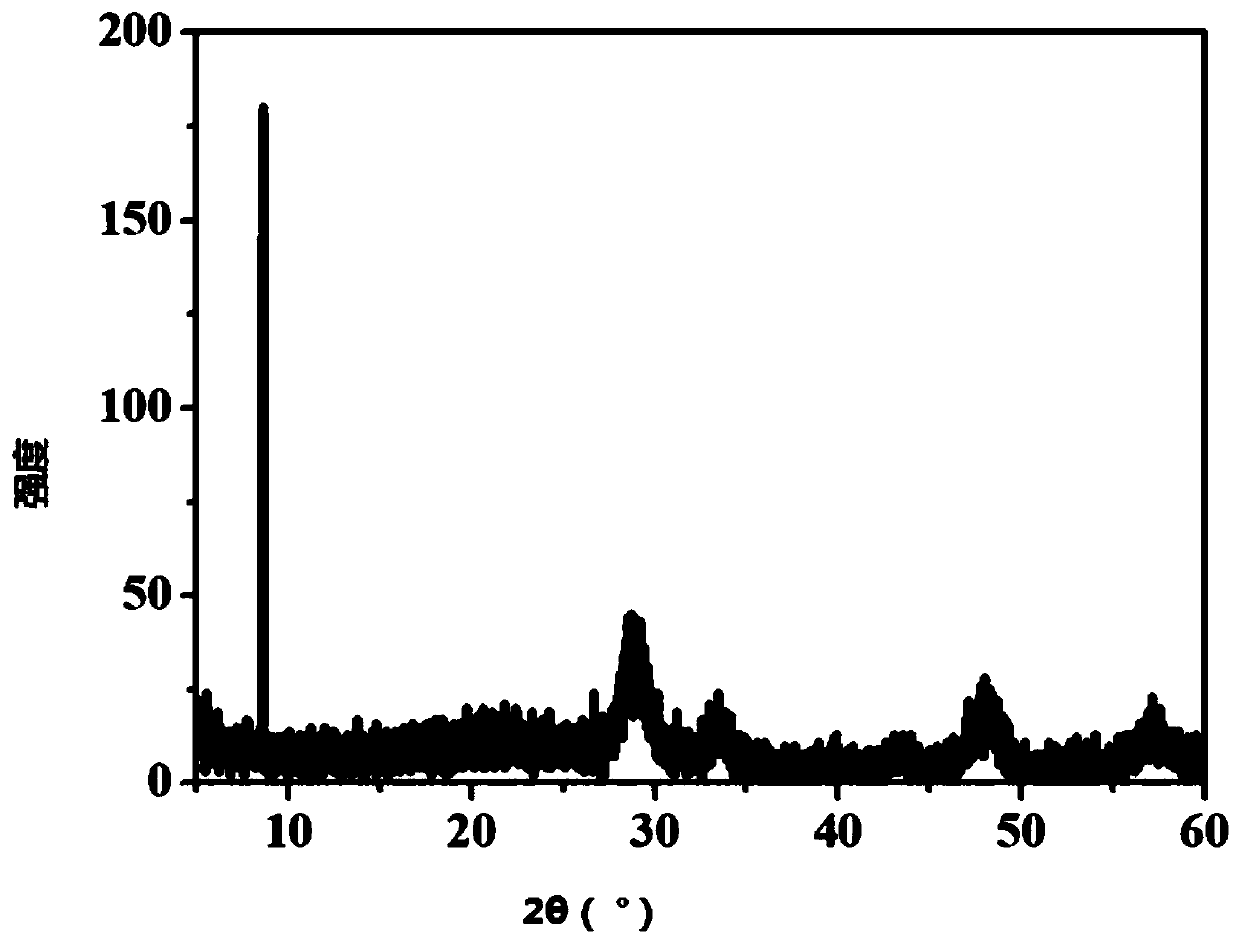

[0021] Specific embodiment 1: The preparation material of the rare earth trimesic acid complex / yttrium trioxide / titanium dioxide composite photoanode of this embodiment includes Ln(BTC) / Y 2 O 3 :Ln 3+ Composite, TiO 2 And FTO conductive glass; FTO conductive glass is conductive glass doped with F; Ln(BTC) / Y 2 O 3 :Ln 3+ Composite and TiO 2 The mass ratio is 1:(100~1000).

specific Embodiment approach 2

[0022] The second embodiment: The difference between this embodiment and the first embodiment is that the surface resistance of the FTO conductive glass is 30Ω / cm 2 , The length is 2cm, the width is 1.5cm, and the thickness is 3mm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: This embodiment is different from specific embodiment one or two: Ln(BTC) / Y 2 O 3 :Ln 3+ The preparation method of the compound is carried out according to the following steps:

[0024] 1. Mix and dissolve trimesic acid and N,N-dimethylformamide, and add them to the aqueous chloride solution to obtain a mixture;

[0025] 2. The mixture obtained in step 1 is subjected to solvent heat treatment, the temperature of solvent heat treatment is 60~100℃, the treatment time is 12~24h, and then washed with methanol and centrifuged, the precipitate obtained by centrifugation is dried, and the drying temperature is 60~80℃. Obtain rare earth trimesic acid complex crystals;

[0026] 3. Put the rare earth trimellitic acid complex crystals obtained in step 2 into a muffle furnace for high-temperature calcination, and the high-temperature calcination temperature is 400-450°C to obtain Ln(BTC) / Y 2 O 3 :Ln 3+ Complex. Others are the same as the first or second embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com